Automatic overturning device with telescopic arms

A technology of automatic flipping and telescopic arms, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problem of flipping to another parallel setting, and achieve the effect of high-precision automatic flipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An automatic turning device with a telescopic arm according to the present invention will be described in detail below with reference to the drawings and embodiments.

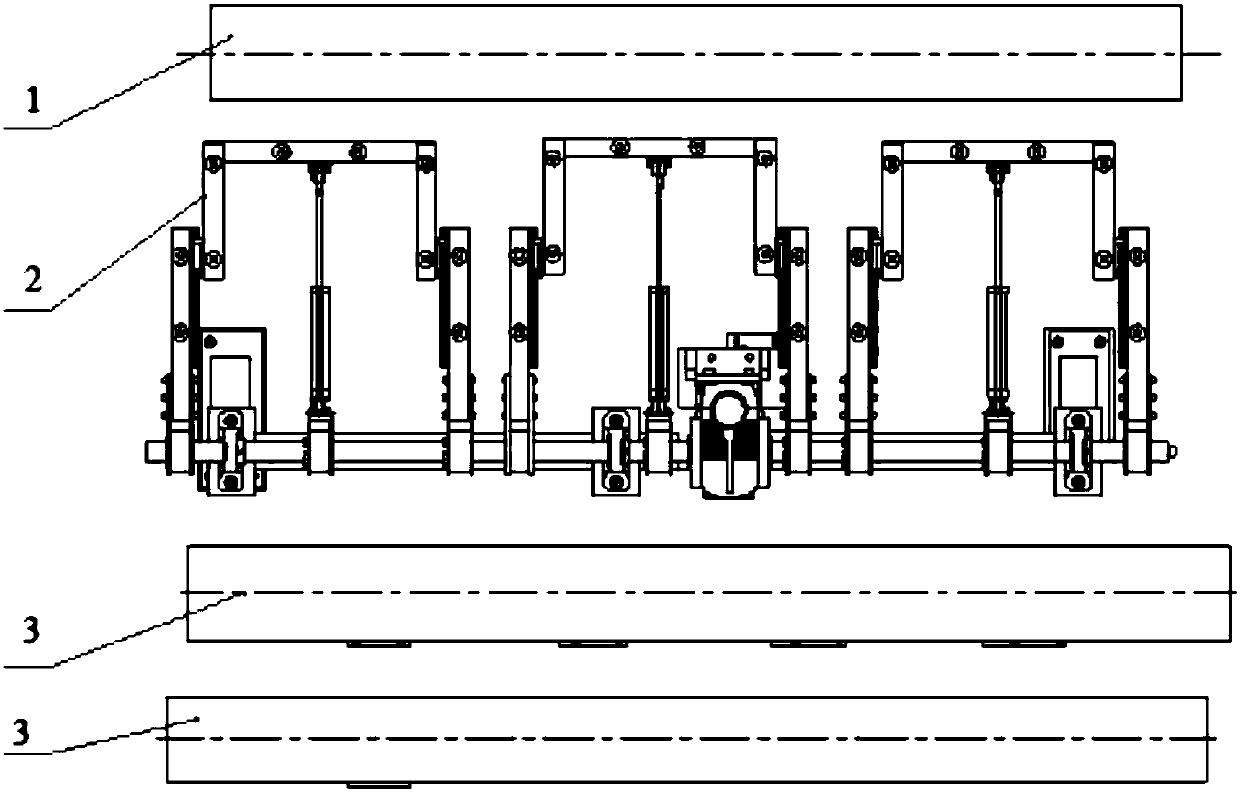

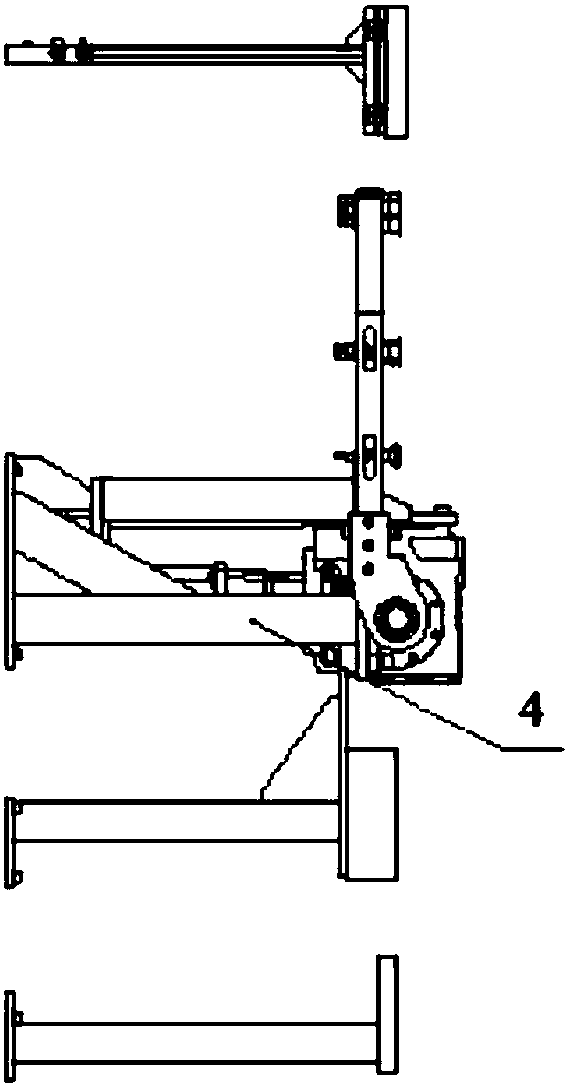

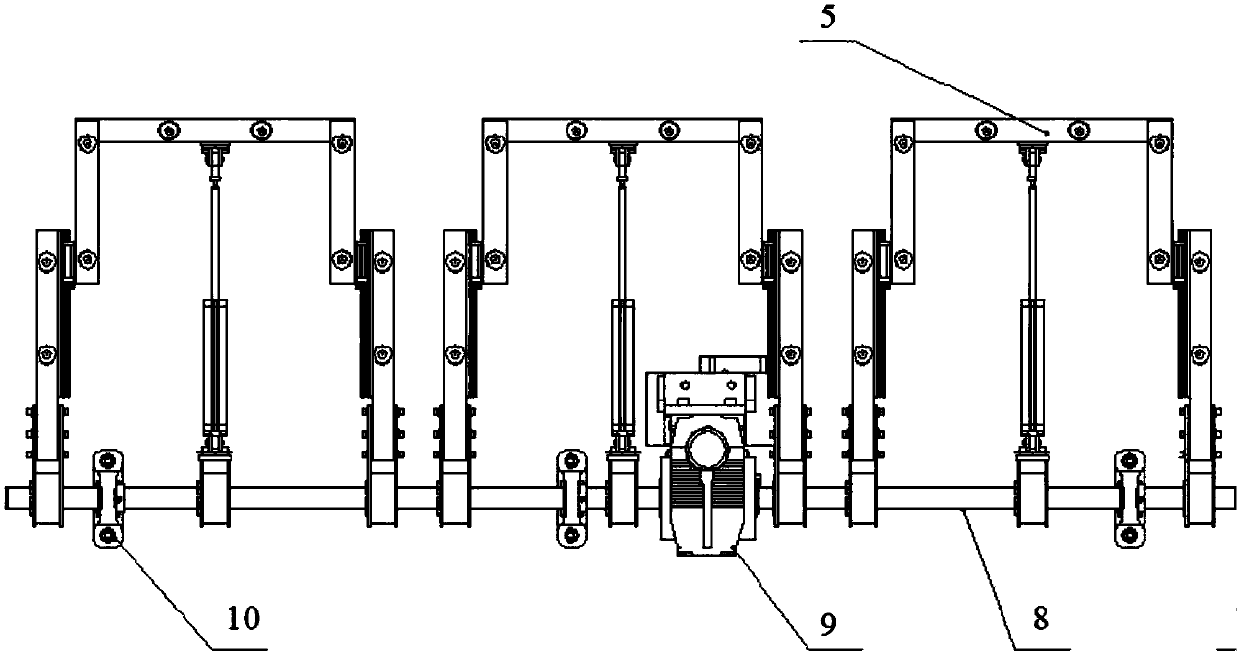

[0023] Such as figure 1 with figure 2 As shown, an automatic turning device 2 with a telescopic arm according to the present invention is arranged between the first sub-production line 1 and the second sub-production line 3 . When the production line is working, the mechanical grippers (not shown) driven by the servo motor clamp the blanks (not shown) one by one, and pass through each sub-production line. Limited by the site, the entire production line is split into two parallel sub-production lines (1, 3). When the sheet is transported to the turnover station, it not only needs to be turned 180°, but also needs to be turned from the first One sub-production line 1 is turned over to the second sub-production line 3 for the next step of processing. Therefore, the automatic turning device 2 of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com