Yarn scraping device for spun bobbin and control method thereof

A spun bobbin and No. 1 technology, applied in the spinning bobbin scraping device and its control field, can solve the problems of high labor intensity and poor cleaning effect of residual yarn, achieve good cleaning effect of residual yarn and improve yarn scraping effect , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

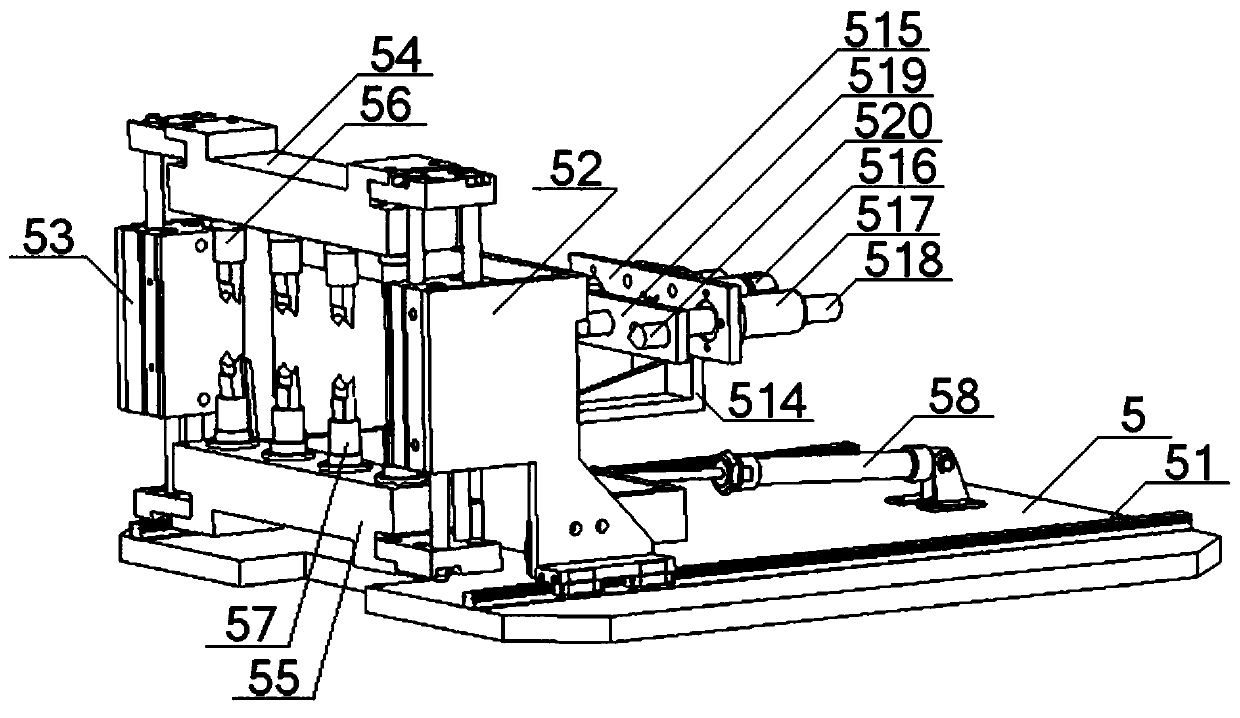

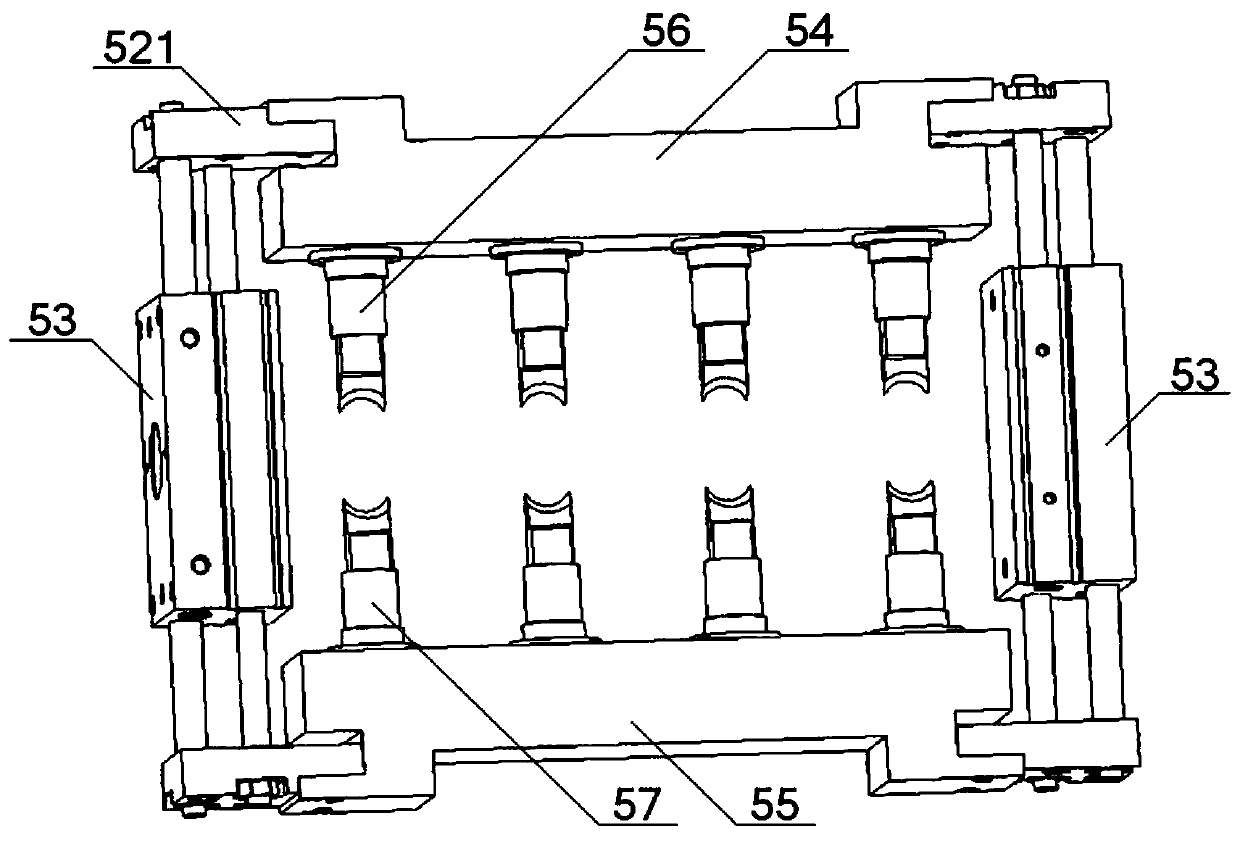

[0058] see Figure 1 to Figure 8 , a spun bobbin yarn scraping device, comprising a circular guide rail 1 and a conveying trolley 2 slidably connected thereon, a timing belt 3 is arranged on the inner side of the circular guide rail 1, the synchronous belt 3 is connected with the conveying trolley 2, and the conveying trolley 2 is horizontally provided with a plurality of sleeves 21 for fitting the spun bobbin 4, and the outer side of the annular guide rail 1 is located near the conveying trolley 2 and is provided with an installation base plate 5, and two guide rails 51 are arranged in parallel on the installation base plate 5, Two guide rails 51 are slidably connected with a No. support 52, and two bidirectional cylinders 53 are vertically and symmetrically arranged on the No. 1 support 52, and one end of the two bidirectional cylinders 53 is vertically connected with a No. One end is vertically connected with No. 2 plate 55, and the No. 1 plate 54 is located on the end face...

Embodiment 2

[0061] Basic content is the same as embodiment 1, the difference is:

[0062] see figure 2 , No. 2 bracket 514 is set on the installation bottom plate 5, No. 1 installation plate 515 and No. 2 cylinder 516 are arranged on No. 2 bracket 514, linear bearing 517 is arranged on No. 1 installation plate 515, and guide Rod 518, guide rod 518 is connected with No. 2 mounting plate 519, is provided with a plurality of top cones 520 on No. 2 mounting plate 519, and the output end of described No. 2 cylinder 516 passes through No. 2 bracket 514, No. 1 mounting plate successively After 515, it is connected with No. 2 mounting plate 519.

[0063] After the No. 1 bracket 52 stops moving, control the No. 2 cylinder 516 to extend, and the No. 2 cylinder 516 drives the No. 2 mounting plate 519 to move in the direction of the spinning bobbin 4 until the top cone 520 tightens the spinning bobbin 4 behind the No. 2 mounting plate 519 stops moving.

Embodiment 3

[0065] Basic content is the same as embodiment 1, the difference is:

[0066] see Figure 1 to Figure 5 The No. 1 yarn scraping knife 56 and the No. 2 yarn scraping knife 57 all include a base 59, a knife case 510, and a cutter head 511. One end of the knife case 510 is set on the base 59, and the other end of the knife case 510 is set on the On one end of the cutter head 511, the other end of the cutter head 511 is provided with a semicircular groove 512, and a spring 513 is arranged in the described cutter housing 510, and one end of the spring 513 is in contact with the base 59, and the other end of the spring 513 is in contact with the cutter head 511. contact, the cutter head 511 can move along the inner wall of the cutter housing 510 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com