Detection mechanism of range hood equipment assembly

A detection mechanism and equipment technology, applied in the fields of tobacco, cigarette manufacturing, application, etc., can solve the problems of low detection efficiency, shutdown of cigarette machines, affecting production, etc., and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

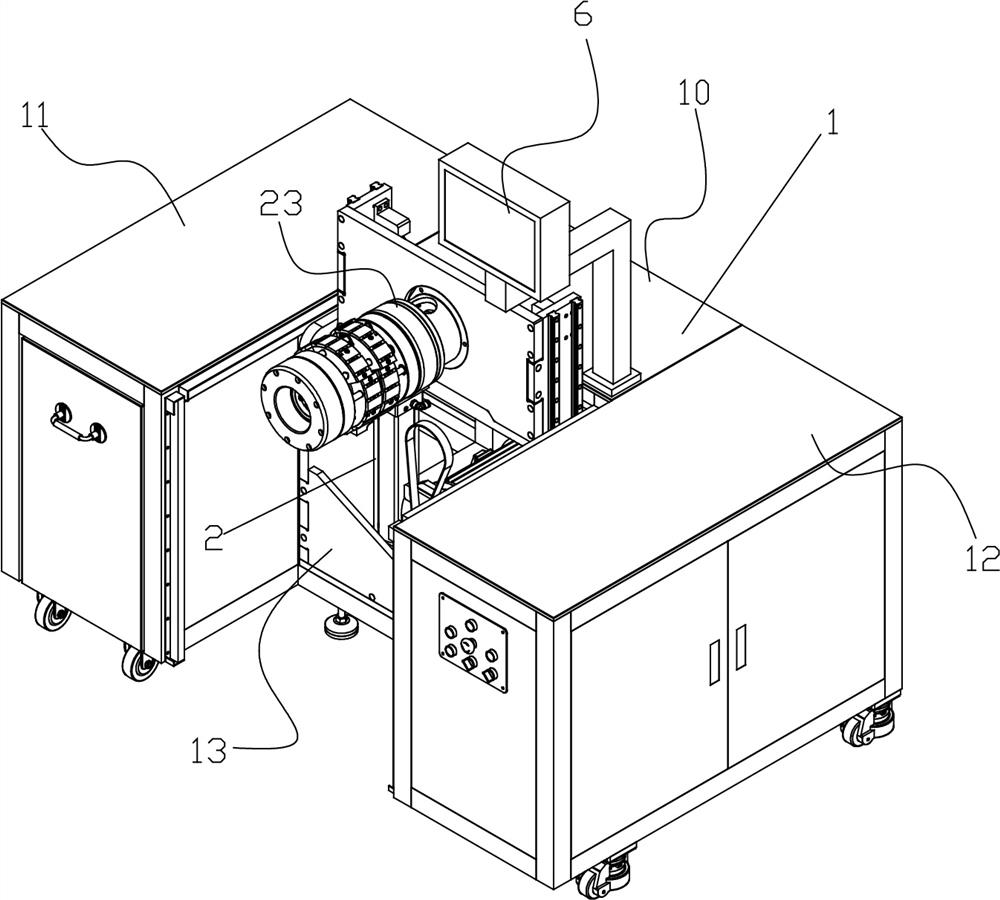

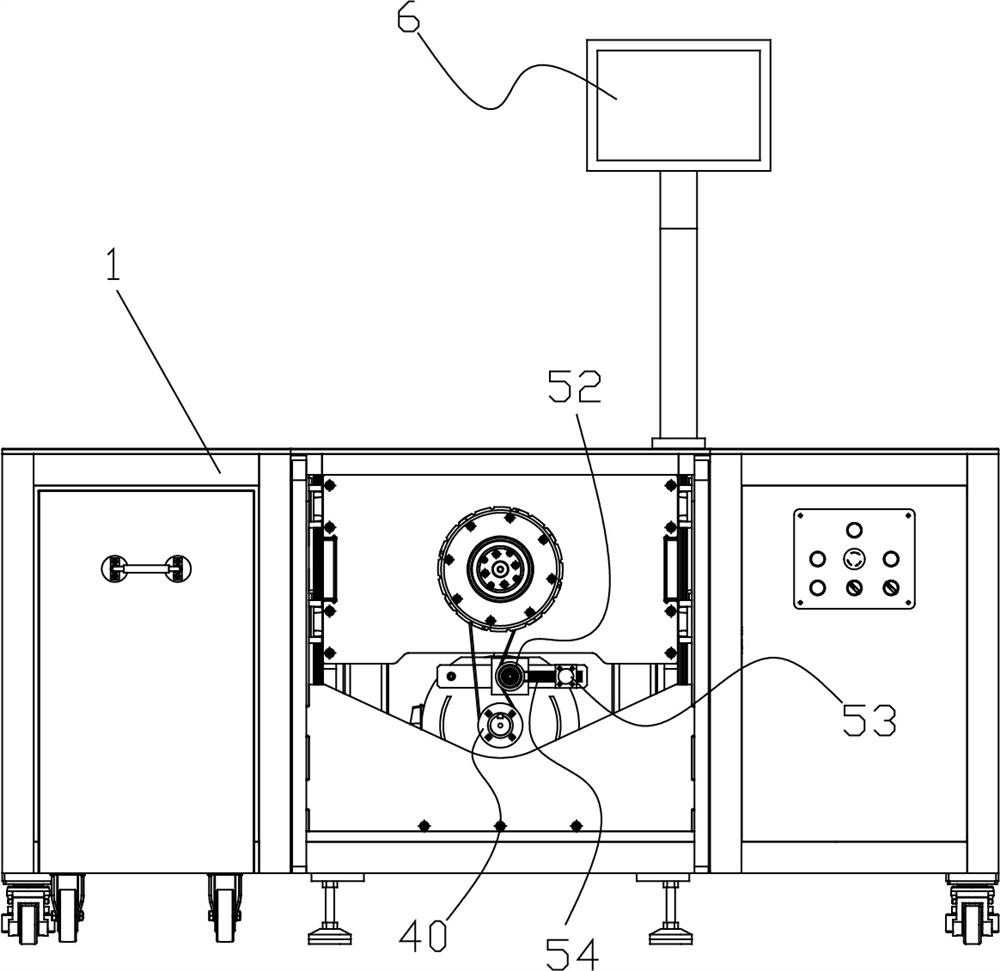

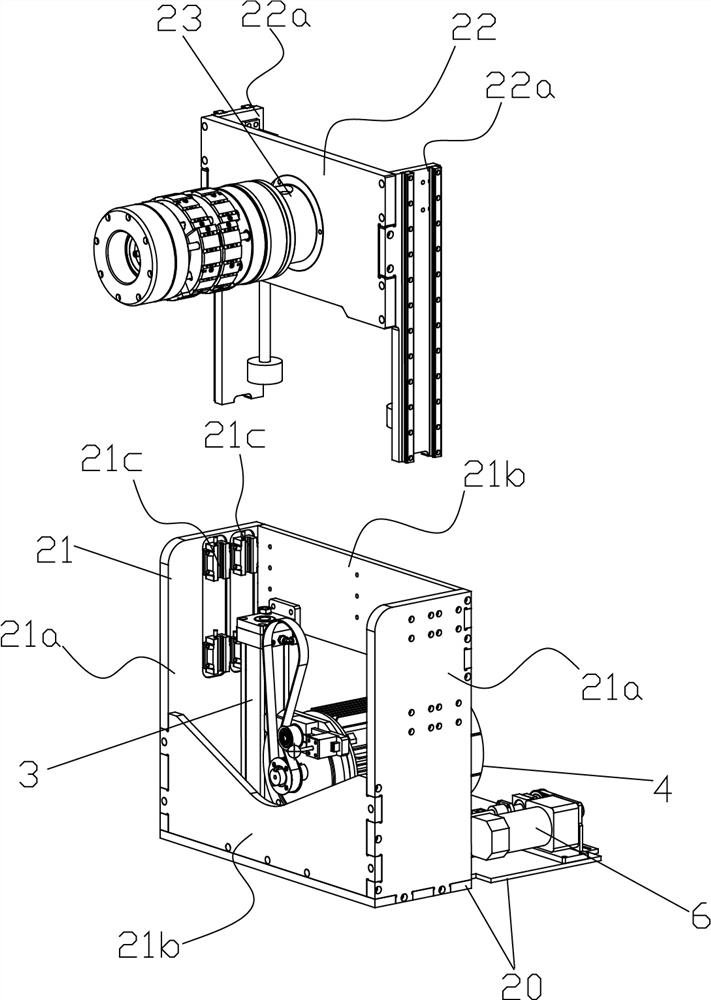

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments: see Figure 1 to Figure 5 ,

[0023] The detection mechanism of the smoke machine equipment assembly includes a workbench 1 , a detection tool 2 arranged in the workbench 1 , a display module 6 and a sensor module matched with the detection tool 2 .

[0024] The workbench 1 includes a test table 10 located in the middle, a tool placement table 11 located on one side of the test table, and an electrical component placement box 12 located on the other side of the test table 10. The test table 10, the tool placement table 11 . The electrical component placement box 12 is U-shaped as a whole, and an open end 13 is formed on one side thereof. The tool placement table 11 can place tools for inspection or maintenance to facilitate operators; the electrical component placement box 12 is used to integrate the electrical components of the whole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com