Multi-station rotary efficient intermediate bulk container cleaning machine

A rotary, multi-station technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem of unguaranteed cleanliness of safety cleaning buckets, simple device structure exposure danger, and worker labor. High strength and other problems, to achieve the effect of small equipment footprint, low labor cost, and good cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

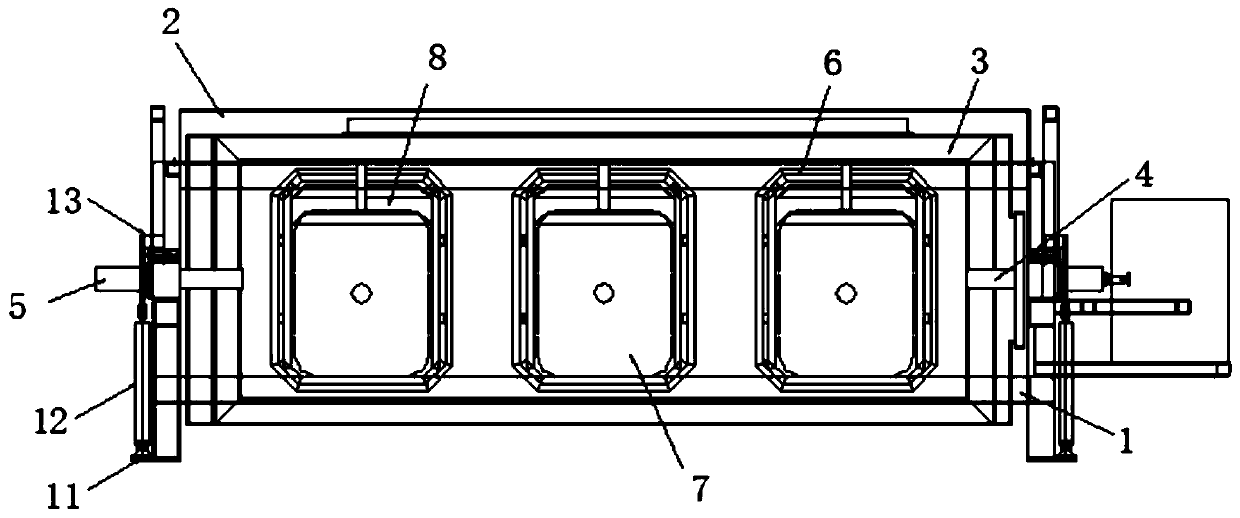

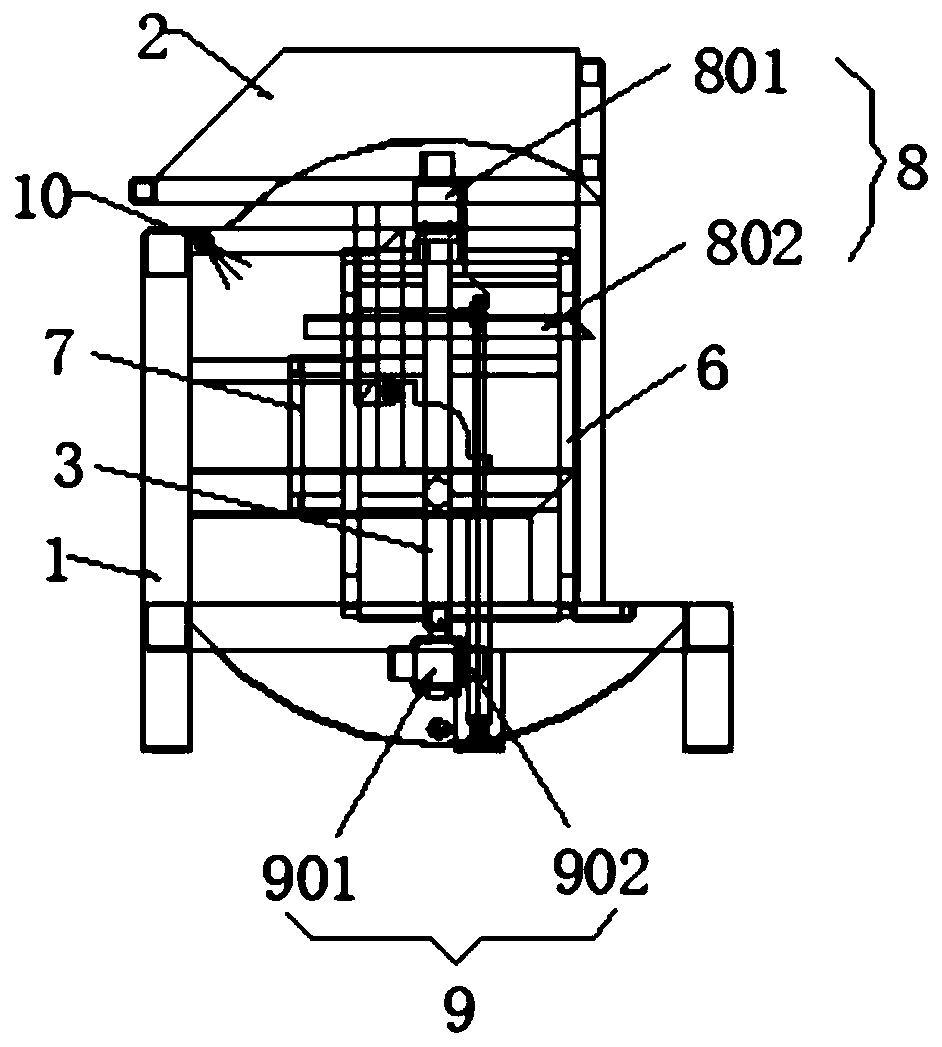

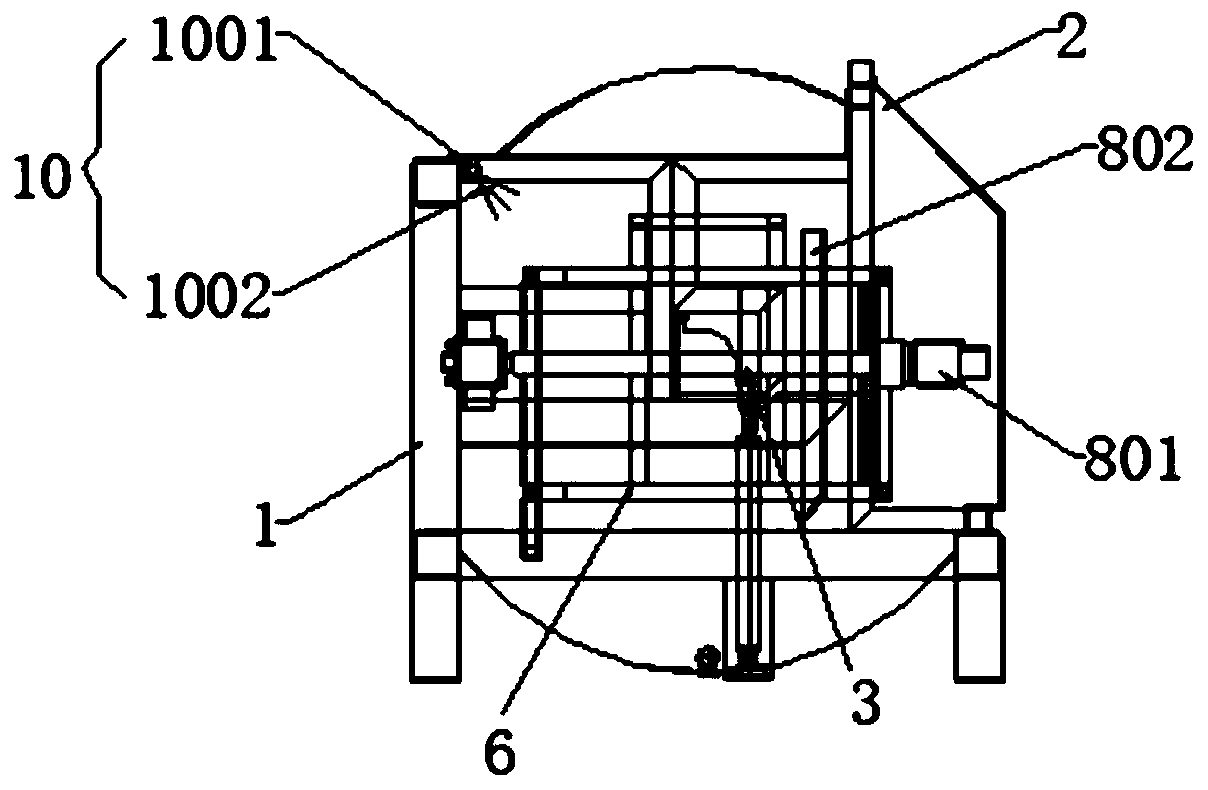

[0024] refer to Figure 1-3 It can be seen that the multi-station rotary high-efficiency internal and external ton barrel cleaning machine of the present invention includes an equipment box 1, and the upper part of the equipment box 1 is connected with a dodge door 2 through a rotating shaft, and a rectangular frame 3 is arranged inside the equipment box 1. The left and right sides of the rectangular frame 3 are integrally provided with connecting shafts 4, and the connecting shafts 4 are rotatably connected to the left and right side walls of the equipment box 1 through bearings, and the connecting shaft 4 on the left side extends to the left outer side of the equipment box 1 and passes through The coupling is equipped with a motor I5, and the inner wall of the rectangular frame 3 is equidistant from left to right with a swinging bed 6, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com