A self-cleaning high-efficiency filter device for non-balanced air pressure guidance and rotation of exhaust gas

A high-efficiency filtration and non-equilibrium technology, applied in the direction of dispersed particle filtration, transportation and packaging, separation methods, etc., can solve the problems of poor exhaust gas filtration effect, reduced purification efficiency, interruption of purification process, etc., and achieve the effect of continuous and efficient purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

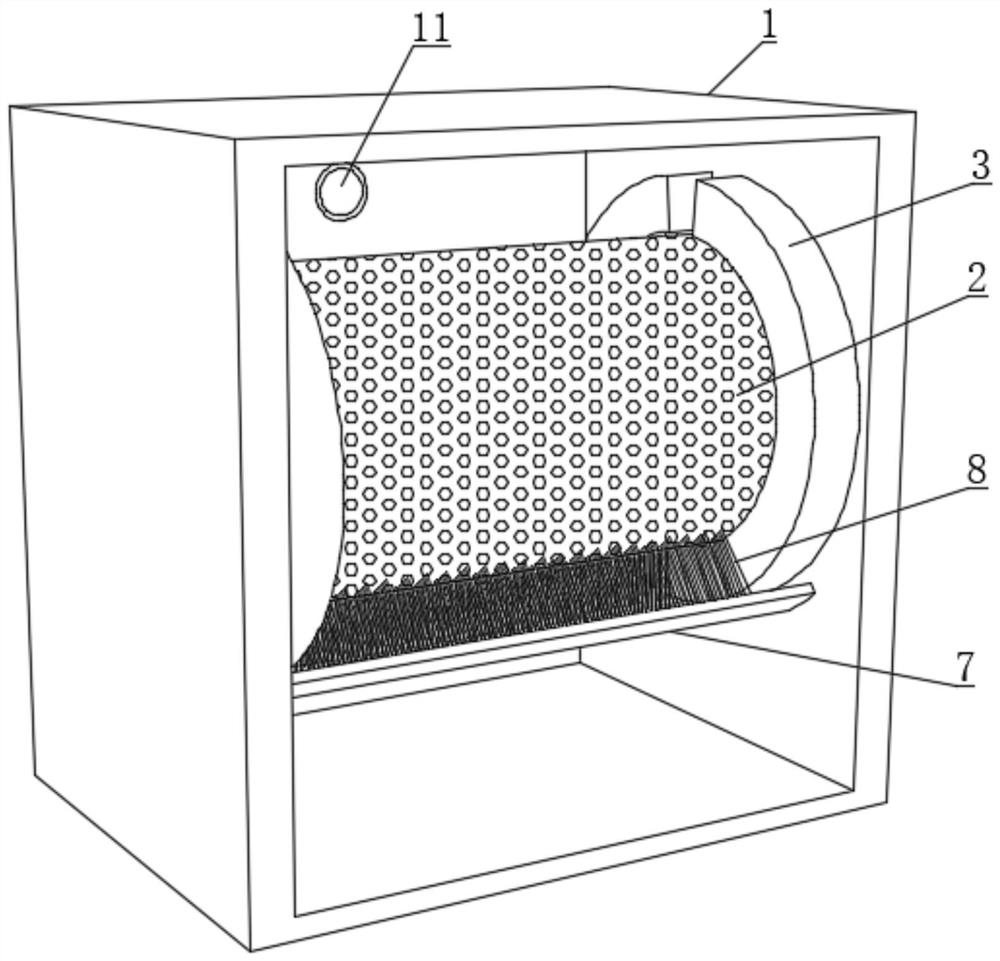

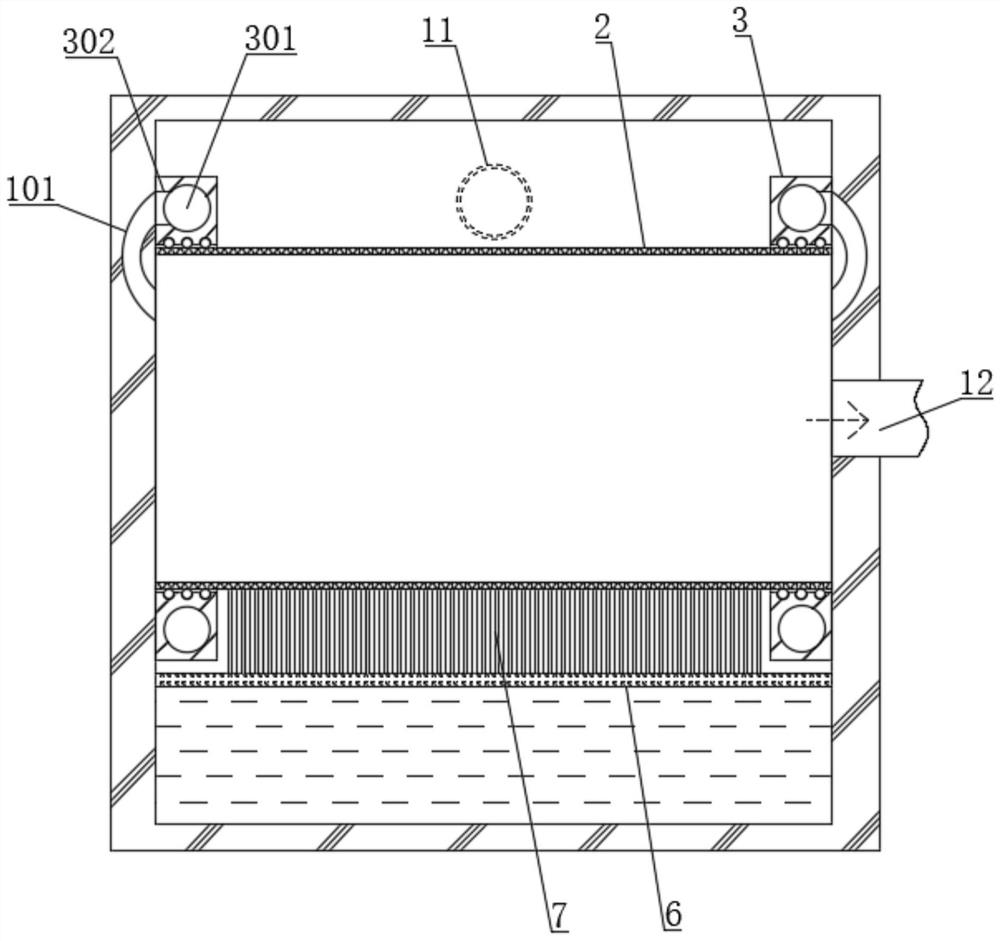

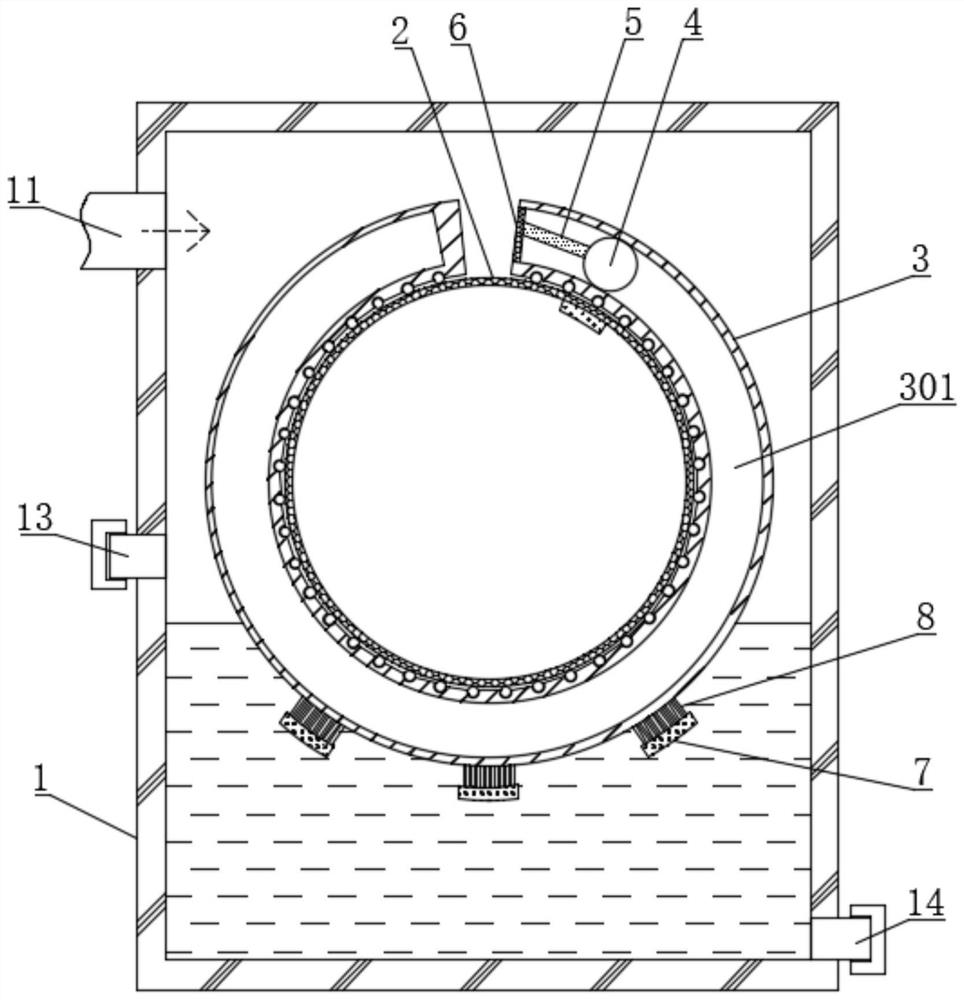

[0043] see figure 1 , an unbalanced air pressure diversion self-cleaning exhaust gas high-efficiency filter device, including a device main body, the device main body includes a filter box 1, the left and right inner walls of the filter box 1 are fixedly connected with notch rings 3, and the inside of the filter box 1 is provided with a filter cartridge 2. The filter cartridge 2 is rotatably connected to the inner side of a pair of gap rings 3, please refer to figure 2 and image 3 , the inside of the gap ring 3 is provided with a semi-closed circular channel 301 with one end communicating with the outer connection, the inside of the semi-closed circular channel 301 is rollingly connected with a sealed magnetic roller ball 4, and the open end of the semi-closed circular channel 301 is fixedly connected with a net. Sheet 6, an elastic drawstring 5 is fixedly connected between the sealed magnetic ball 4 and the net sheet 6, please refer to Figure 4 and Figure 5 , the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com