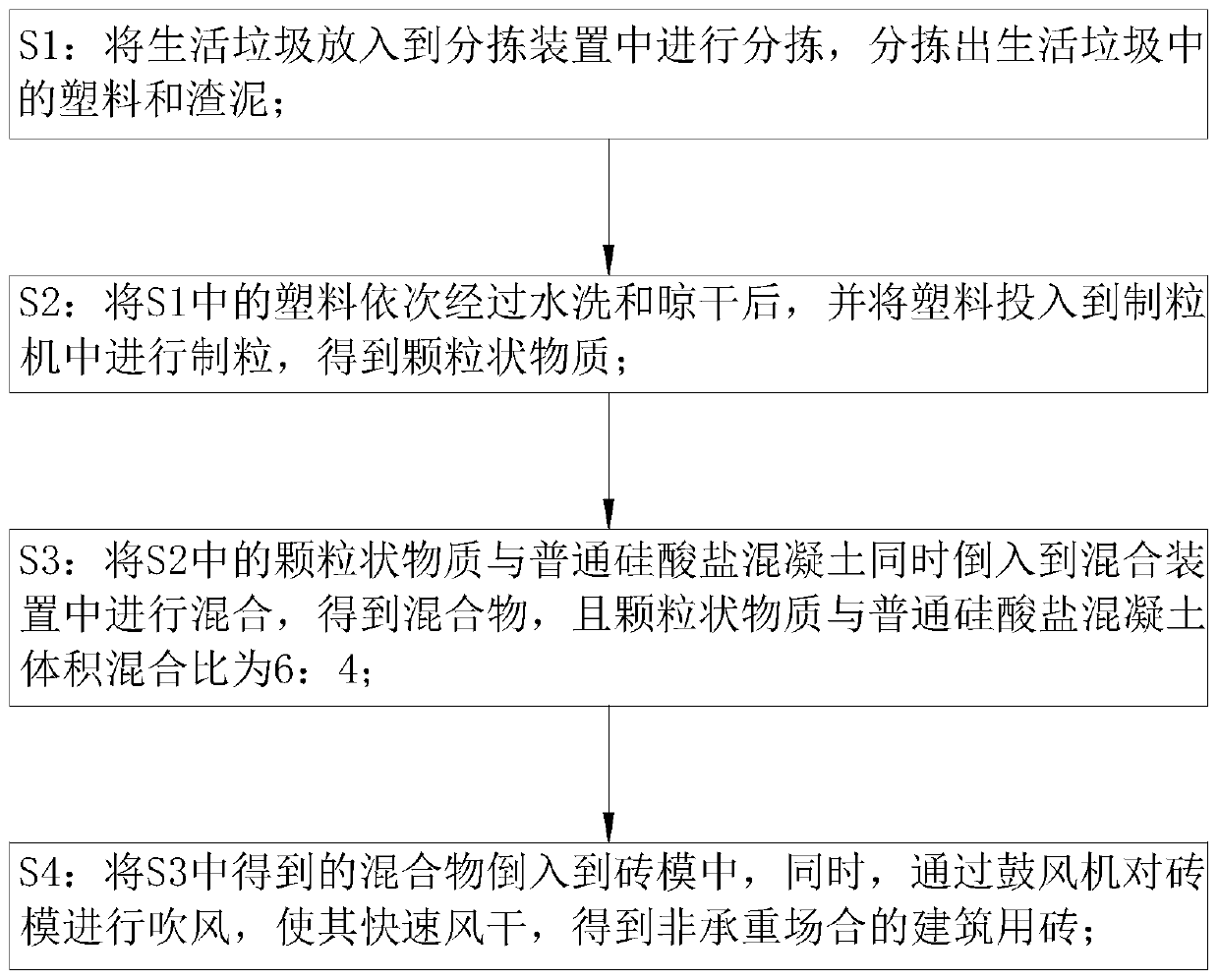

Retreatment process for domestic garbage

A domestic waste reprocessing technology, applied in grain processing, sieves, grills, etc., to achieve the effect of reducing manufacturing costs, simple process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

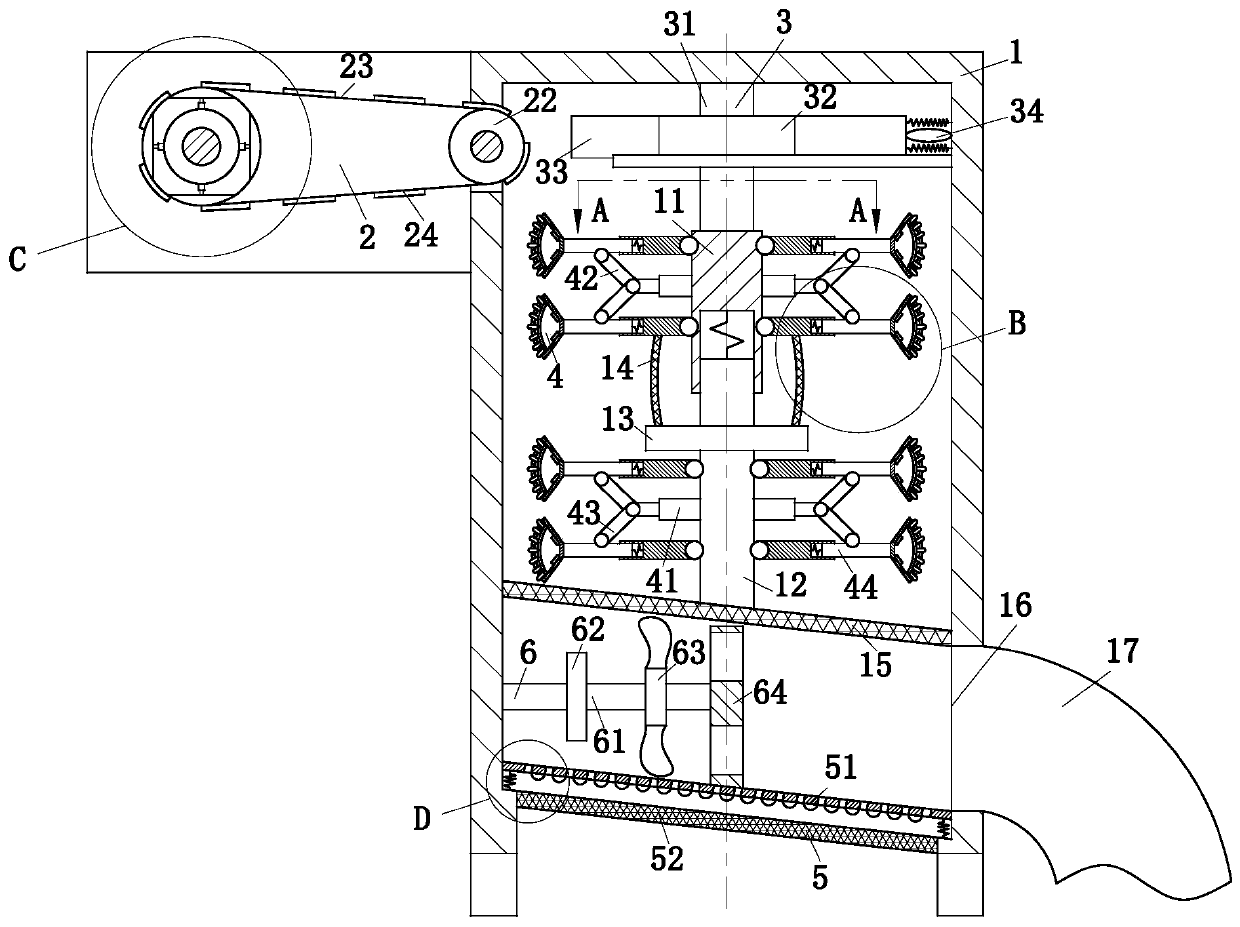

Embodiment approach

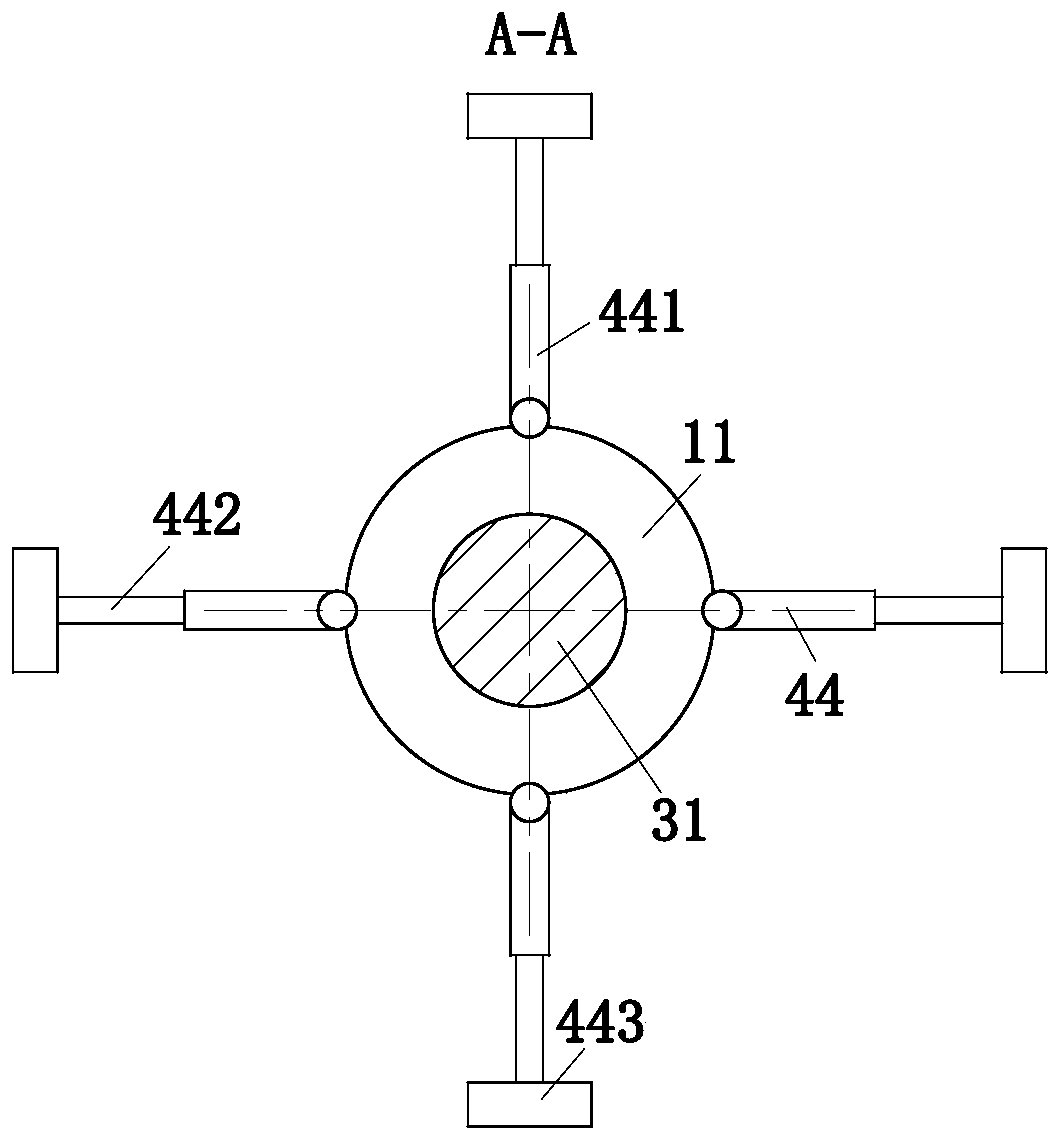

[0037] As an embodiment of the present invention, the No. 1 wheel 21 is composed of No. 2 cylinder 211, No. 3 wheel 212 and arc-shaped blocks 213; the number of arc-shaped blocks 213 is four and distributed in a circle; the two One end of the No. cylinder 211 is fixedly connected with the No. 1 arc-shaped plate 71, and the other end of the No. 2 cylinder 211 is fixedly connected on the outer ring of the No. 3 wheel 212. The No. 3 wheel 212 is installed on the mounting plate by rotating the shaft. No. spring 54 is squeezed and the gas produced acts on No. 2 cylinder 211, making No. 1 belt 23 vibrate. In the present invention, the first wheel 21 is composed of the second cylinder 211, the third wheel 212 and the arc block 213. On the one hand, the gas generated by the extrusion of the hollow first spring 54 is used to avoid adding extra power source, thereby improving the utilization rate of resources; on the other hand, the second cylinder 211 pushes the arc block 213 to move b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com