Janus magnetic imprinted nanosheet, preparation method and application thereof

A magnetic molecular imprinting, nanosheet technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the overlapping of functional sites and regions, poor separation effect, low selectivity, etc. problem, to achieve the effect of improving specific identification, large adsorption capacity and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

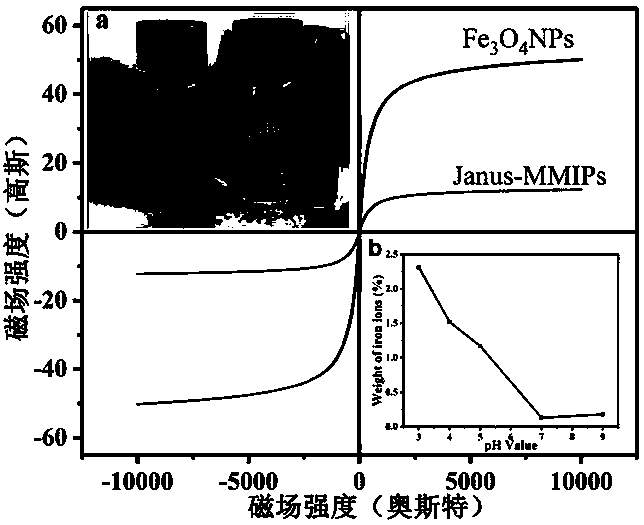

[0040] (1) Carboxy-modified Fe 3 o 4 Granule preparation

[0041] Mix 100 mL of 0.2 mol / L sodium oleate aqueous solution with 100 mL of 0.2 mol / L ferric chloride aqueous solution. The brown iron oleate complex was obtained by filtration, dispersed with n-hexane, washed three times with distilled water, and dried in a desiccator. Add the complex to 20.0 mL of ethanol containing 10% oleic acid at room temperature. The mixture was transferred to an autoclave and heated to 180 °C for 5 hours. After the reaction, the black oleic acid-capped Fe was washed with ethanol 3 o 4 Nanoparticles (Fe 3 o 4 NPs) and separated with a magnet. The product was redispersed in toluene at a concentration of 10 mg / mL.

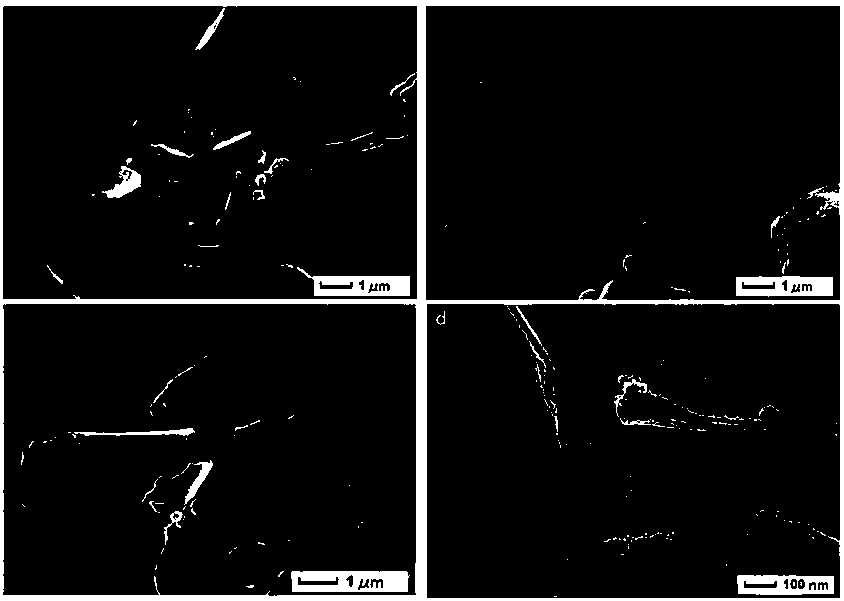

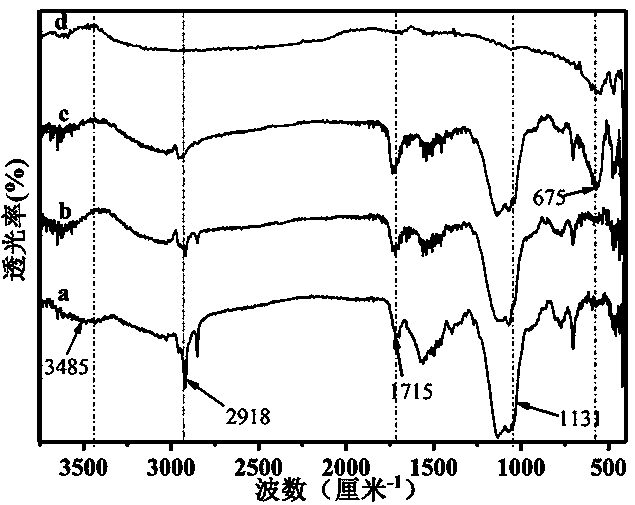

[0042] (2) Preparation of Janus nanosheets

[0043] A certain amount of 10 wt% HSMA and water were used as the continuous phase in a beaker, and the pH was adjusted to 3-4 with 2 mol / L HCl solution. Take a certain amount of solid paraffin, add a certain amount of 3-aminopro...

Embodiment 2

[0054] (1) Carboxy-modified Fe 3 o 4 Granule preparation

[0055] Mix 100 mL of 0.2 mol / L sodium oleate aqueous solution with 150 mL of 0.2 mol / L ferric chloride aqueous solution. The brown iron oleate complex was obtained by filtration, dispersed with n-hexane, washed three times with distilled water, and dried in a desiccator. Add the complex to 20.0 mL of ethanol containing 12.5% oleic acid at room temperature. The mixture was transferred to an autoclave and heated to 180 °C for 5 hours. After the reaction, the black oleic acid-capped Fe was washed with ethanol 3 o 4 Nanoparticles (Fe 3 o 4 NPs) and separated with a magnet. The product was redispersed in toluene at a concentration of 10 mg / mL.

[0056] (2) Preparation of Janus nanosheets

[0057] A certain amount of 10 wt% HSMA and water were used as the continuous phase in a beaker, and the pH was adjusted to 3-4 with 2 mol / L HCl solution. Take a certain amount of solid paraffin, add a certain amount of 3-amin...

Embodiment 3

[0063] (1) Carboxy-modified Fe 3 o 4 Granule preparation

[0064] Mix 100 mL of 0.2 mol / L sodium oleate aqueous solution with 200 mL of 0.2 mol / L ferric chloride aqueous solution. The brown iron oleate complex was obtained by filtration, dispersed with n-hexane, washed three times with distilled water, and dried in a desiccator. Add the complex to 20.0 mL of ethanol containing 15% oleic acid at room temperature. The mixture was transferred to an autoclave and heated to 180 °C for 5 hours. After the reaction, the black oleic acid-capped Fe was washed with ethanol 3 o 4 Nanoparticles (Fe 3 o 4 NPs) and were separated by a magnet. The product was redispersed in toluene at a concentration of 10 mg / mL.

[0065] (2) Preparation of Janus nanosheets

[0066] A certain amount of 10 wt % HSMA and water were used as the continuous phase in a beaker, and the pH was adjusted to 3-4 with 2 mol / L HCl solution. Take a certain amount of solid paraffin, add a certain amount of 3-amin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com