Dry pastry processing technology

A processing technology and dry point technology, applied in the field of dry point processing technology, can solve the problems affecting the quality, taste and color of dry point finished products, poor process control, etc., to ensure effectiveness and safety, ensure disinfection quality, and ensure The effect of effective disinfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

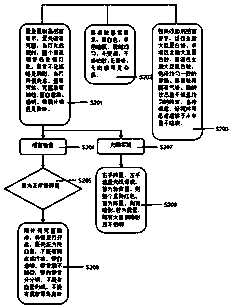

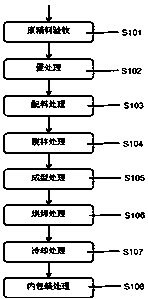

[0090] This embodiment: as figure 1 As shown, a dry point processing technology, including raw and auxiliary materials acceptance S101: In accordance with the requirements of the relevant national "Food Incoming Inspection Specifications" and "Inspection Standards for Raw Materials", inspect the sensory properties of eggs and egg products, standard powder and powder additives Requirements, physical and chemical indicators and microbial indicators;

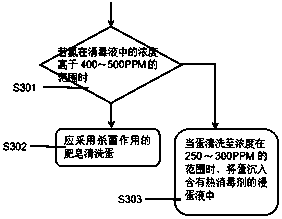

[0091] Egg processing S102: cleaning and disinfection of eggs and egg products;

[0092] Ingredient processing S103: Add food flavor or add it as an auxiliary material to food flavor;

[0093] Stirring process S104: placing the processed ingredients in a blender and stirring process S104;

[0094] Forming processing S105: combine the stirred ingredients with the dough, and form the combined ingredients and dough on the dry point molding machine for S105;

[0095] like Figure 5 As shown, baking treatment S106: Carry out corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com