Optical wavelength conversion component and light emitting device

A light wavelength conversion and component technology, applied in the direction of luminescent materials, filters, electrical components, etc., can solve the problems of increased transmission, uneven color, decreased durability, etc., and achieve the effect of sufficient fluorescence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0049] [1-1. Structure of Optical Wavelength Converter]

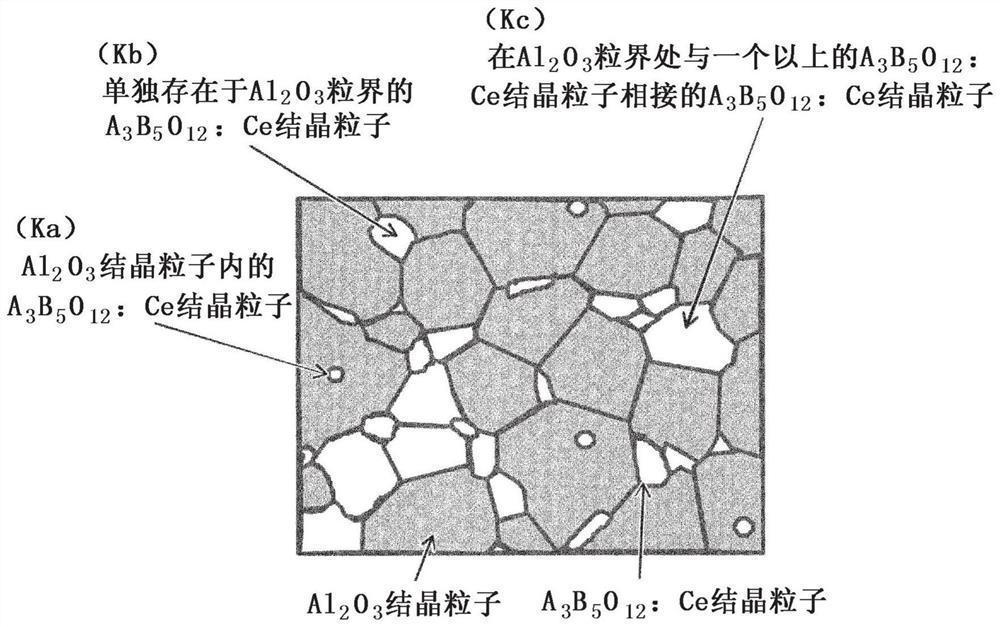

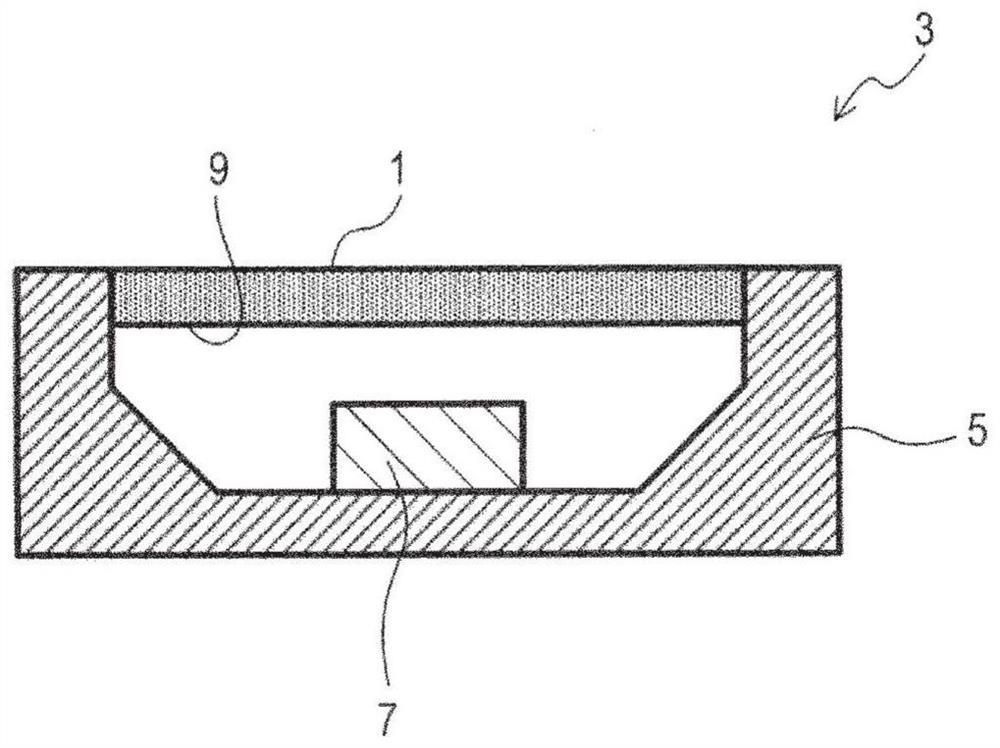

[0050] First, the optical wavelength conversion member of the embodiment will be described. Such as figure 1 As shown, the optical wavelength conversion component 1 of the embodiment (refer to figure 2 ) is, for example, a plate-shaped ceramic sintered body, composed of Al 2 o 3 Crystalline particles and by formula A 3 B 5 o 12 : Crystal particles of a component represented by Ce (hereinafter sometimes referred to as A 3 B 5 o 12 : Ce crystal particles) are composed of polycrystalline bodies as the main component.

[0051] In this optical wavelength conversion component 1, A 3 B 5 o 12 A and B in are at least one element selected from the following element groups:

[0052] A: Sc, Y, lanthanides other than Ce

[0053] B: Al, Ga.

[0054] Furthermore, A of the range of 20 μm square of the cross section of the ceramic sintered body 3 B 5 o 12 : Among the N Ce crystal particles, there will be Al 2 o 3 T...

Embodiment 1

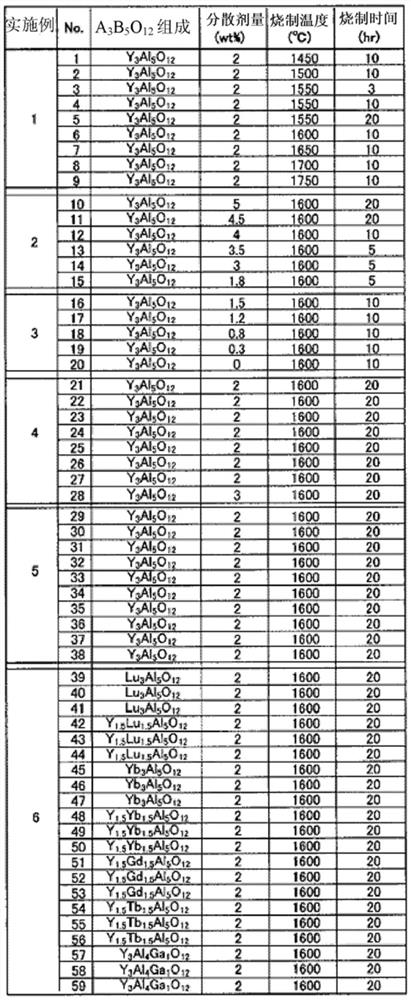

[0076] According to the conditions shown in Table 1 and Table 2 below, samples of ceramic sintered bodies of Nos. 1 to 9 were produced. In addition, No. 1-9 among each sample is a sample within the range of this invention.

[0077]Specifically, for each sample, the YAG (Y 3 Al 5 o 12 ) to 21 vol%, and Al was weighed so that the Ce concentration was 1 mol% relative to Y in YAG. 2 o 3 (average particle size 0.3μm), Y 2 o 3 (average particle size 1.2μm), CeO 2 (average particle size 1.5 μm).

[0078] This was put into a ball mill together with pure water and a predetermined amount of dispersant (2% by weight in terms of solid matter relative to the raw material powder), and pulverized and mixed for 12 hours. The obtained slurry was dried and granulated, and the granulated product was used to produce a molded body. Then, the molded body was fired in the atmosphere under normal pressure at a firing temperature of 1450° C. to 1750° C. and a holding time of 3 to 20 hours. T...

Embodiment 2

[0102] By the same manufacturing method as in Example 1, as shown in Table 1 and Table 2 below, samples of ceramic sintered bodies (samples of Nos. 10 to 15) were prepared, and evaluated in the same manner.

[0103] However, at the time of preparation, the dispersant amount was varied within the range of 1.8 to 5 wt%, and the firing time was varied within the range of 5 to 20 hours. In addition, among each sample, No. 11-14 is a sample within the range of this invention, No. 10, 15 is a sample outside the range of this invention (comparative example).

[0104] As a result, in any of the samples, the relative density was 99% or more, and they were sufficiently densified. And it can be seen that, except for No.10, Al 2 o 3 The average crystal grain size is in the range of 0.3-10μm, A 3 B 5 o 12 : Ce (YAG: Ce) has an average crystal grain size in the range of 0.3 to 5 μm. Furthermore, as can be seen from Table 2 below, Nos. 11 to 14 in which X, Y, and Z were within the rang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com