Lubricant composition comprising polyalkylene oxide

A technology of lubricant composition and polyalkylene oxide, applied in the direction of lubricant composition, base material, petroleum industry, etc., can solve the problems of undisclosed and unsuitable lubricants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation of the lubricant composition of the present invention and / or any of its steps may be a batch process or a continuous process. In a preferred embodiment, the method for mixing the components used to prepare the lubricant composition; and the mixing equipment used in the method can be any container and auxiliary equipment well known to those skilled in the art.

[0042] In one embodiment, the present invention includes a combination or blend of at least two components comprising, for example: (a) a first low viscosity (eg, less than about 4 cSt) polyalkylene oxide based fluid composed of A combination of at least two different polyalkylene oxide fluids prepared using a first alcohol such as dodecanol as an initiator and having an average molecular weight of less than about 600 Da; and (b) based on a high viscosity (e.g., greater than about 4cSt) Polyalkylene oxide fluids made from a combination of at least two different polyalkylene oxide fluids using a se...

example

[0057] The following examples and comparative examples further illustrate the present invention in more detail, but should not be construed as limiting the scope thereof.

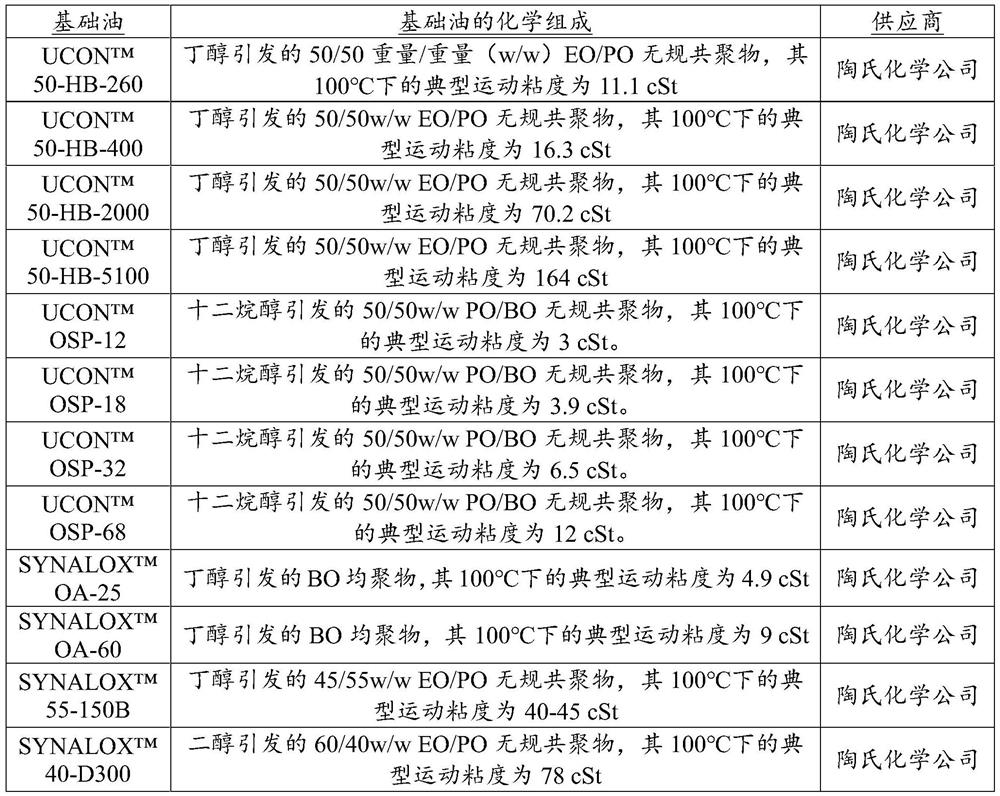

[0058] Various terms and designations are used in the following examples and comparative examples, which are explained as follows:

[0059] "EO" means ethylene oxide.

[0060] "PO" means propylene oxide.

[0061] "BO" means butylene oxide.

[0062] "UCON TM OSP" stands for oil-soluble polyalkylene glycol.

[0063] The traction coefficients as given herein are derived from the Stribeck curves obtained from the discs used on PCS small tractors 3 / 4 Inch ball measurements form, both ball and disc are made of AISI 52100 steel. Both balls and discs had a surface finish Ra (arithmetic mean deviation) better than 0.01 microns. Measurements were performed at 80°C and 120°C, a load of 50 Newtons, a slide-to-roll ratio (SRR) of 150%, and a speed of 2000 mm / s to 100 mm / s. The test was continuously measured 1...

example 1-2 and comparative example A

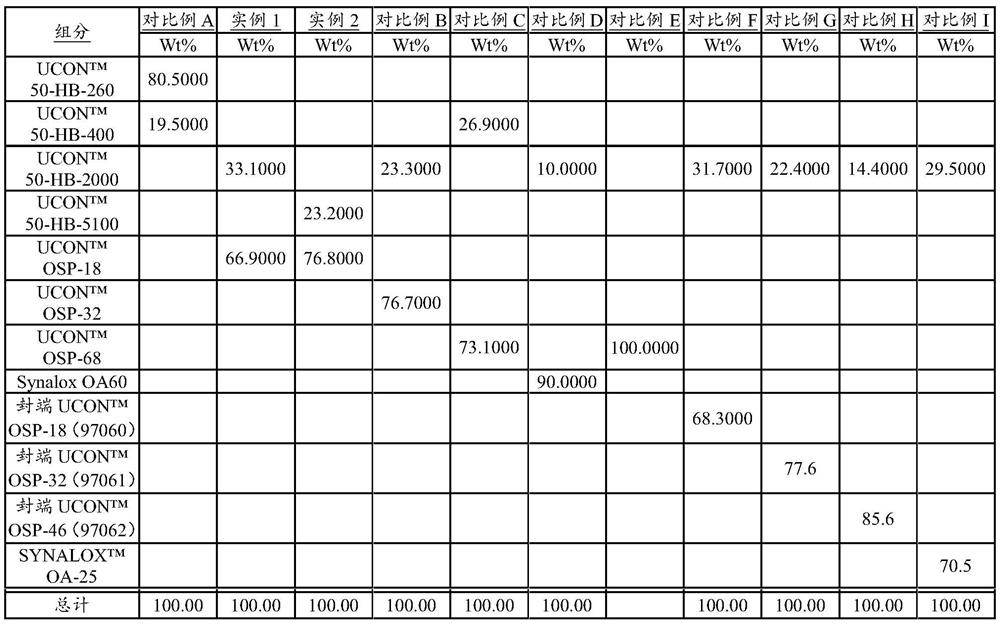

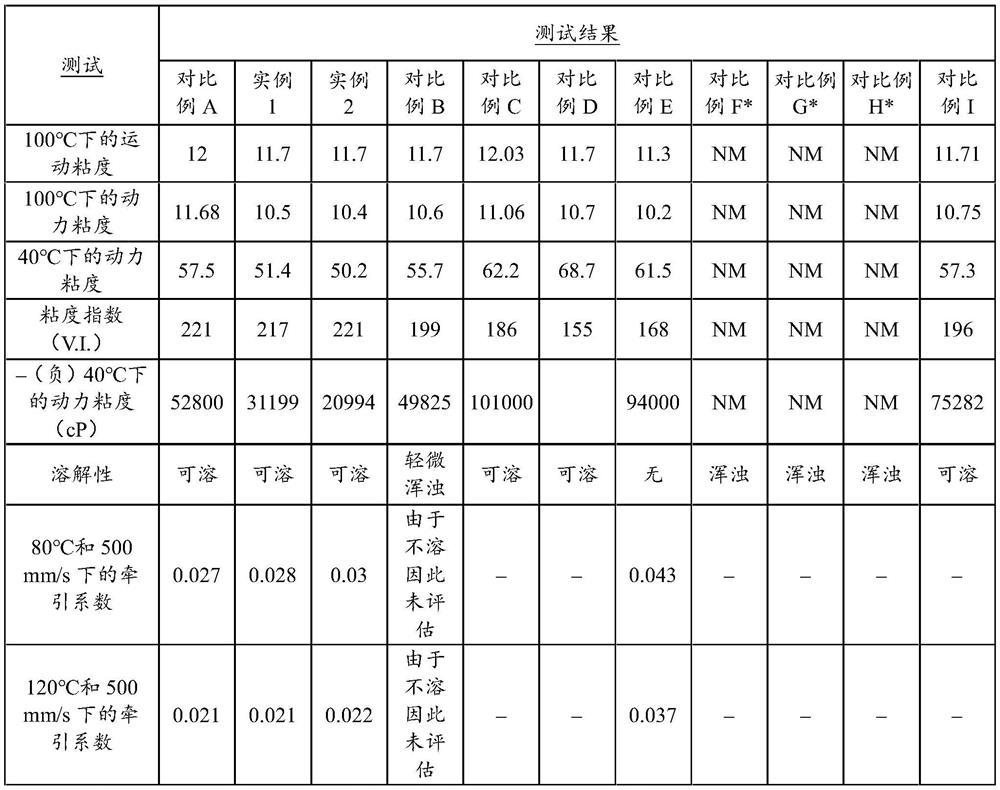

[0074] Table II lists the composition or formulation of various base fluids. Table III presents the results of the evaluation of various formulations having the components listed in Table II. Table III highlights the kinematic and dynamic viscosities, viscosity indices, low temperature dynamic viscosities, solubility and traction coefficients for different combinations of the various base fluids that make up the formulations. All fluids had a target viscosity of 11.7 cSt at 100°C.

[0075] Table II - Various Base Fluids

[0076]

[0077] Table III – Test Results for Various Base Fluids

[0078]

[0079] *These examples were not measured due to insolubility. NM = "Not Measured".

[0080] As described in Table III above, Comparative Example A (Comparative Example A) shows standard UCON TM 50-HB-260 and UCON TM Viscosity and Traction Coefficients of 50-HB-400 and comparing these properties with UCON highlighted in Comparative Example E (Comparative Example E) T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com