A quick lock wire electrical connector

A wire-locking electrical and connector technology, applied in the direction of clamping/spring connection, etc., can solve the problems of poor reliability and unrealistic electrical connectors, and achieve the effects of reliable wire-locking state, increased reliability, and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

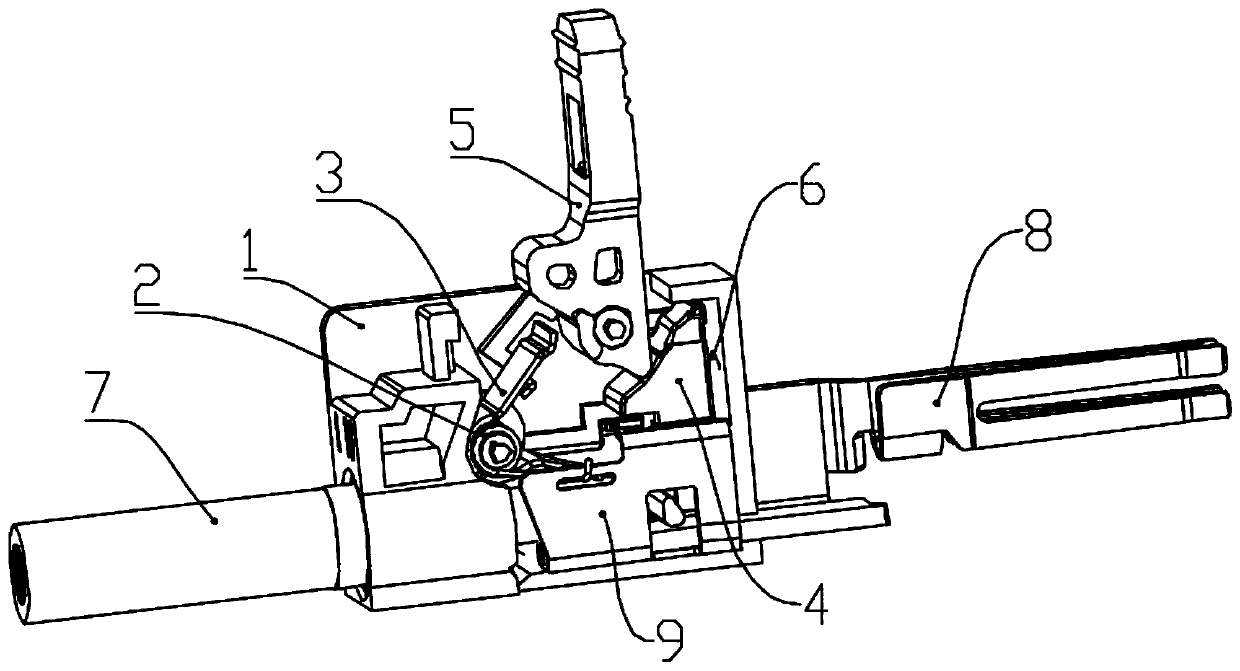

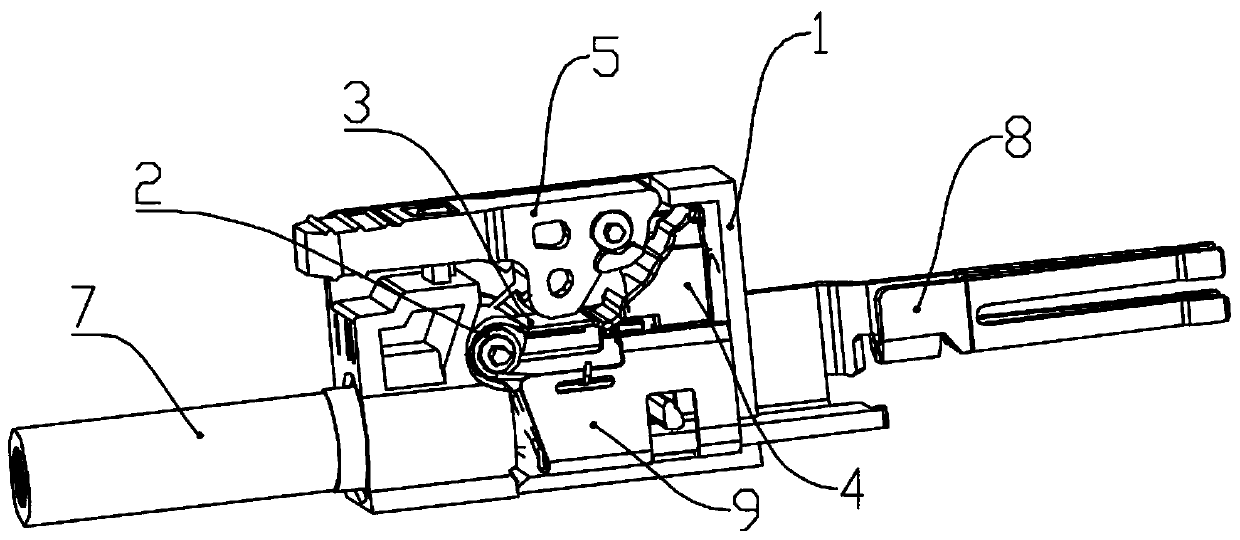

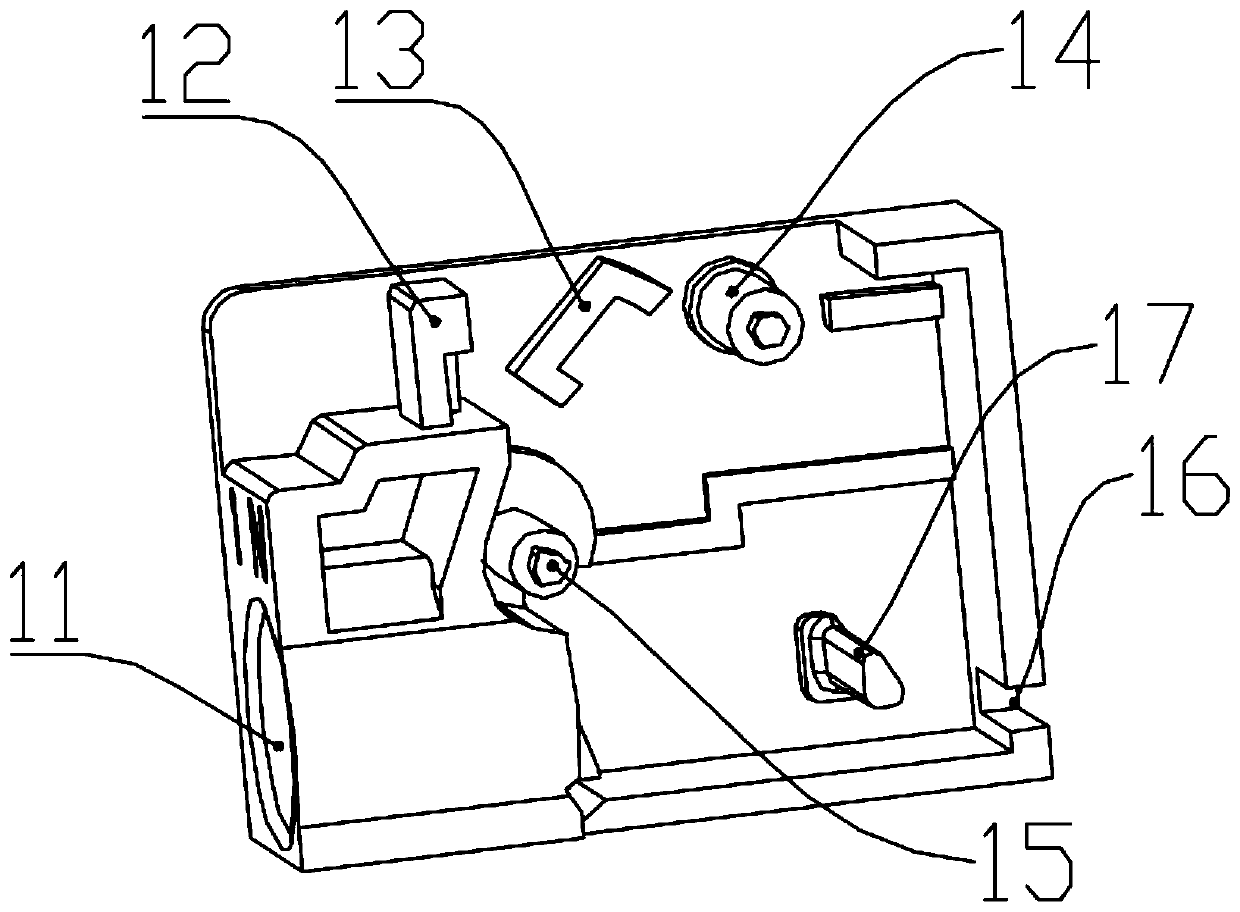

[0031] like Figure 1 to Figure 9 As shown: this embodiment discloses a fast locking wire electrical connector: including a base 1, a torsion spring 2, a shrapnel 3, a slider 4, a handle 5, a contact terminal 8 and a crimping frame 9; the base 1 is provided with Wiring hole 11, shrapnel support shaft 15 and terminal installation hole 16, slider 4 is provided with sliding slope 41, guide groove 42 and positioning step 43, handle 5 is provided with handle top 52 and shrapnel crimping boss 53, crimping frame 9 A slider support arm 92 is provided, and the elastic piece 3 includes an elastic end 31 and a crimping arm 32 .

[0032] The handle 5 is hinged to the base 1 (it can be rotated at a certain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com