Processing device and method of curved-surface grating

A curved surface grating and processing device technology, which is applied to the photoplate making process, diffraction grating, optics, etc. print quality, flexible choice of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail through specific examples below, but the embodiments of the present invention are not limited thereto.

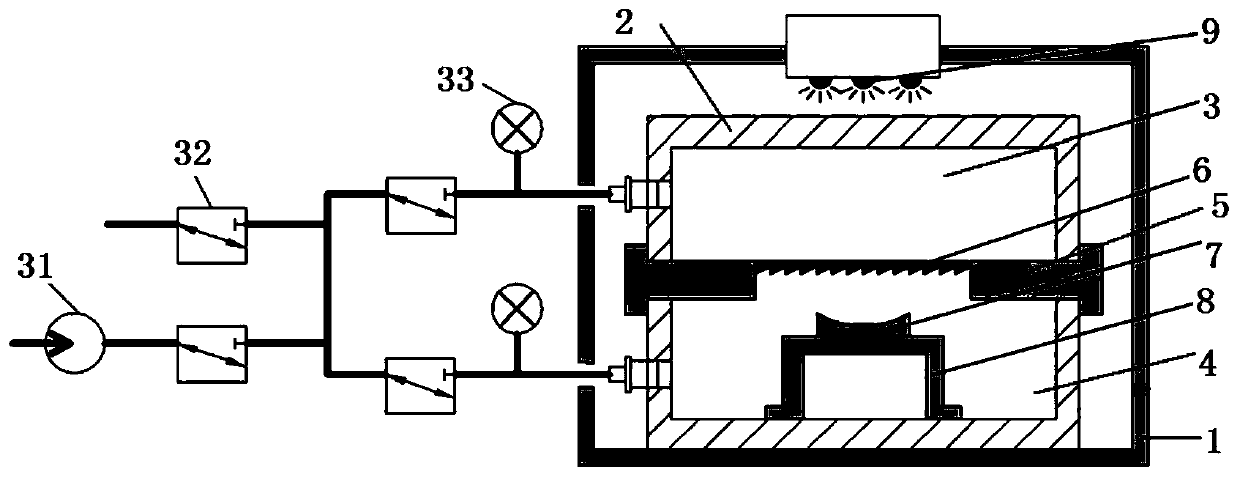

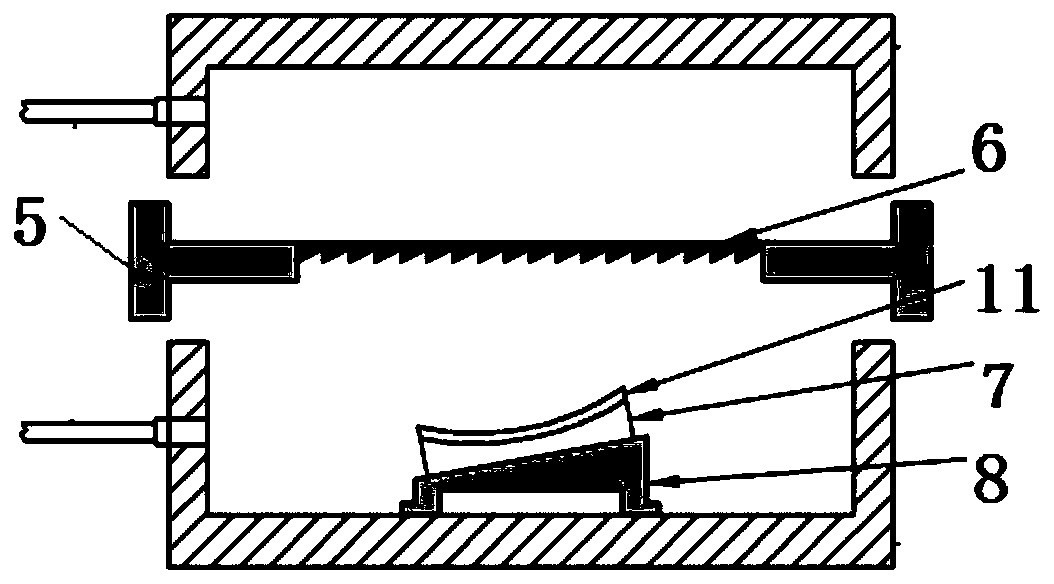

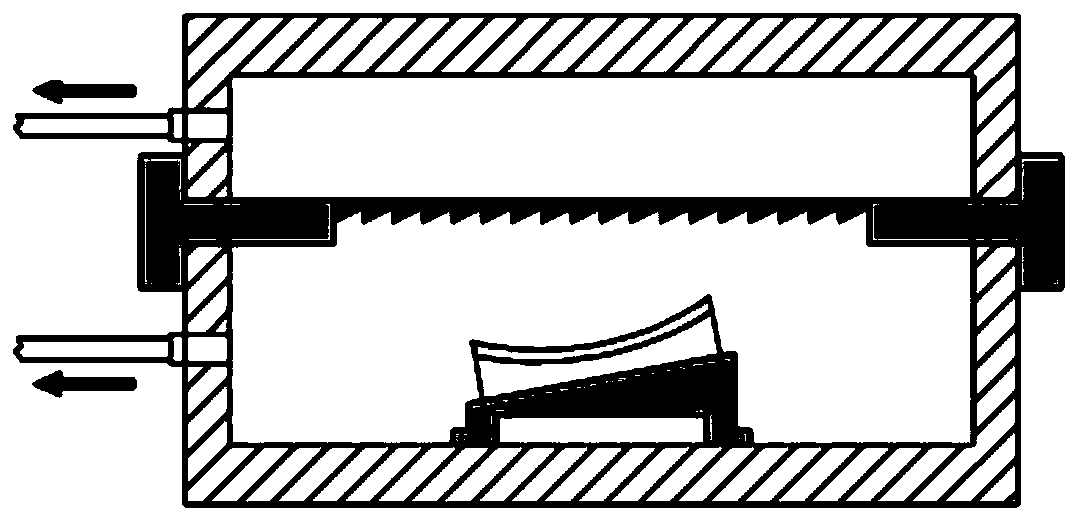

[0044] The invention provides a processing device for a curved surface grating, the structure of which is as follows figure 1 As shown, it includes an embossing cavity 2, a control gas path and an ultraviolet light source 9. The middle part of the imprinting cavity 2 is provided with a PDMS (polydimethylsiloxane) soft template installation position 5, and the PDMS soft template installation position 5 is used for Install the PDMS soft template 6. After the PDMS soft template 6 is installed on the PDMS soft template installation position 5, the imprint chamber 2 is divided into two compartments, the upper compartment 3 and the lower compartment 4. The PDMS soft template 6 and the PDMS soft template The sealing process is carried out between the installation positions 5, so that the upper compartment 3 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com