Flexible shearing-anti-shearing test fixture and shearing testing method thereof

A shear test and fixture technology, applied in the direction of using a stable shear force to test material strength, strength properties, measuring devices, etc., can solve problems such as partial load, influence test results, and shear stress results. Small influence, avoid direct contact, reduce friction effect

Pending Publication Date: 2019-05-03

HUNAN IND POLYTECHNIC

View PDF2 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there are the following shortcomings. First, it cannot meet the test of shearing and reverse shearing of metal materials during use; secondly, it cannot conduct shearing tests in the direction of thickness of thin plates; finally, it cannot simulate the use of plates for connection purposes. Performance test under dual loads of tension and shear in the actual working process

[0003] A Chinese patented shear test fixture (Patent No.: CN 104535414 B) is a solution for the interlayer shear strength test of materials, which cannot be used for shear tests of

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

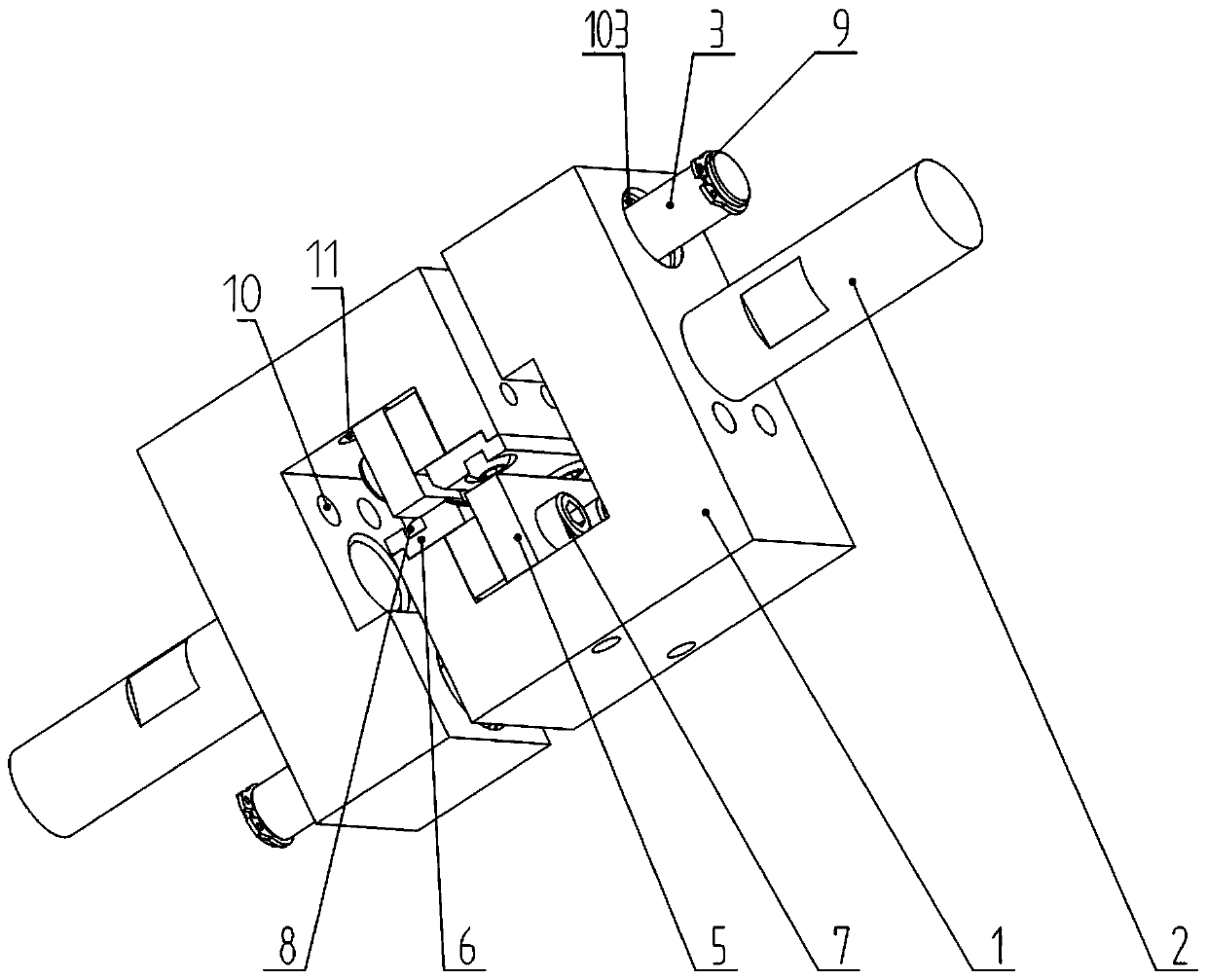

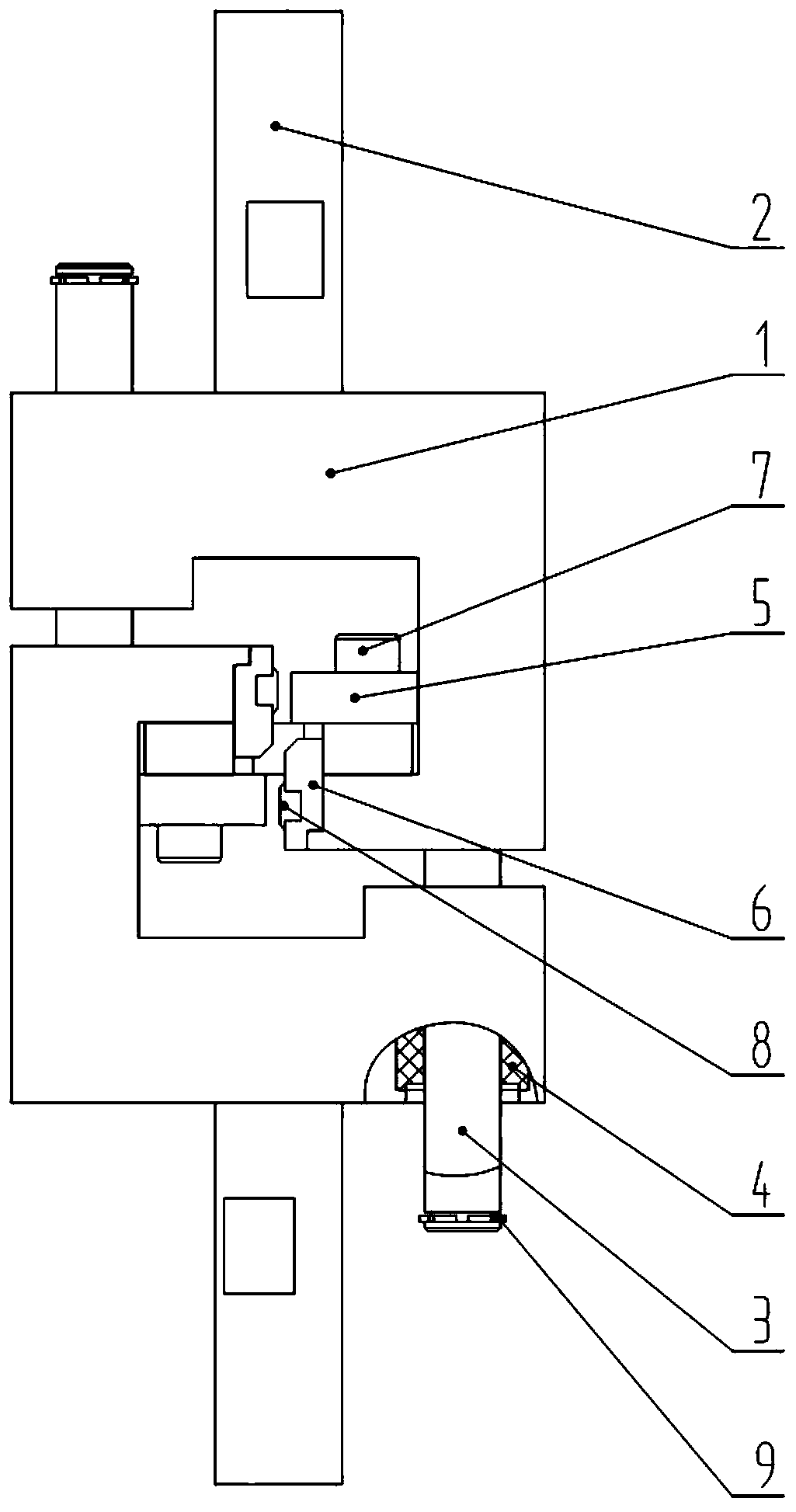

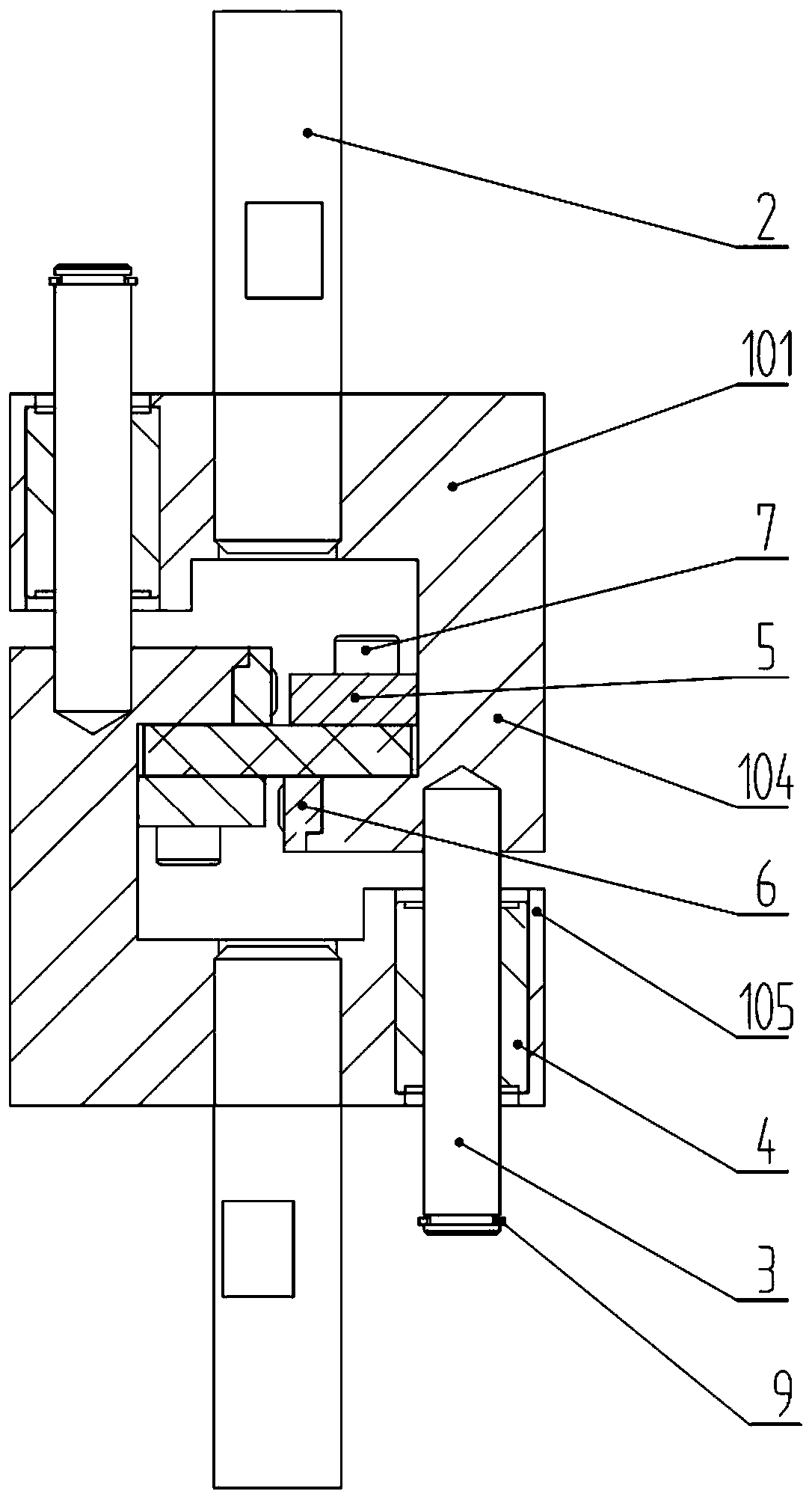

The invention discloses a flexible shearing-anti-shearing test fixture which comprises clamp bodies, a pull rod, a guide rod, a linear bearing, a pressing plate and a shearing knife. Meanwhile, the invention also discloses a shearing testing method of the flexible shearing-anti-shearing test fixture. The flexible shearing-anti-shearing test fixture and the shearing testing method thereof have thefollowing beneficial effects: the shearing and anti-shearing tests of a board can be realized without the need to replacing parts; and shearing testing of boards with different thicknesses and thin plates in a thickness direction can be realized. The distance of the shearing knife plane can be adjusted by replacing the fixture shearing knife; and the mechanical properties of the board under the double-load stretching-shearing effect at different distances can be tested. On the basis of the pull rod structure, the fixture can be installed at a universal mechanical stretching testing machine tocarry out shearing and anti-shearing tests. The two clamp bodies employ a reverse symmetric mounting structure and the pull rod is installed at the symmetric central line of the fixture assembly, so that the influence on the test result by the unbalance loading is reduced effectively.

Description

technical field [0001] The invention relates to the technical field of mechanical experiment equipment, in particular to a flexible shear-reverse shear test fixture and a shear test method thereof. Background technique [0002] At present, the method stipulated in the "Shear Test Method for Aluminum Alloy Products for Structural Parts" (GB / T34487-2017) issued by the state can conduct shear tests on plate or cylindrical specimens. However, there are the following shortcomings. First, it cannot meet the test of shearing and reverse shearing of metal materials during use; secondly, it cannot conduct shearing tests in the direction of thickness of thin plates; finally, it cannot simulate the use of plates for connection purposes. The performance test under the double load of tension and shear in the actual working process. [0003] A Chinese patented shear test fixture (Patent No.: CN 104535414 B) is a solution for the interlayer shear strength test of materials, which cannot b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/04G01N3/24

Inventor 陈超王志辉

Owner HUNAN IND POLYTECHNIC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com