Granular material automatic packaging device

A technology for automatic packaging and granular materials, applied in food science, floor fabrics, household appliances, etc., can solve the problems of low efficiency, complex production equipment cost, narrow use range, etc., to reduce the time of rolling, guarantee Label integrity, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

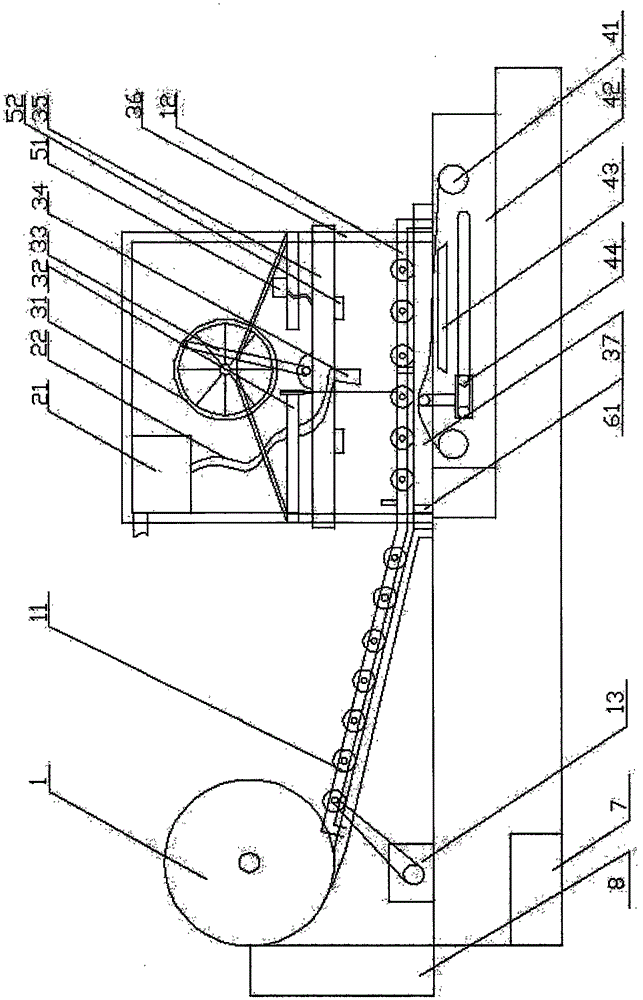

[0057] Embodiment one, such as Figure 1-2 , 5, 6, 9, 11-14 show: a kind of automatic packaging device for granular materials, including a control mechanism that is arranged on the frame and is connected with the packaging mechanism, the paper feeding mechanism and the storage mechanism signaled on the frame, A material storage mechanism is set above the packaging mechanism, a paper feeding mechanism is set at the rear of the packaging mechanism, and an intermittent mechanism for transporting granular materials to the packaging mechanism is set between the material storage mechanism and the packaging mechanism; the intermittent mechanism includes a movable platform 35 and a guide column 36 For the intermittent power module, the movable platform 35 is arranged on the frame at the packaging mechanism through the guide column 36, and the intermittent power module is arranged above the movable platform 35 and fixedly connected with the frame. The intermittent power module comprise...

Embodiment 2

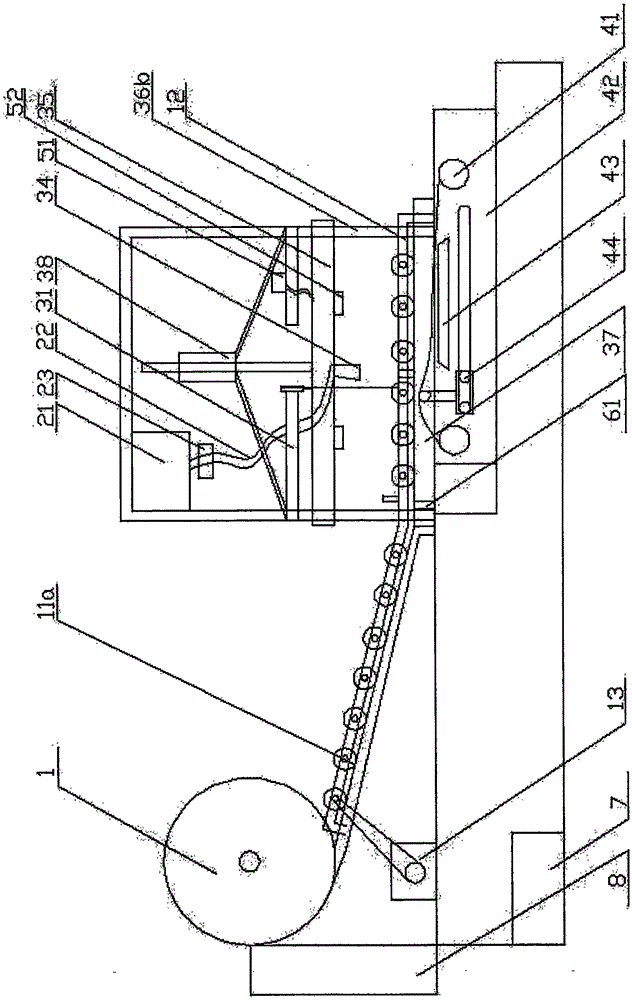

[0060] Embodiment two, such as Figure 3-4, 5-9, and 11-14 show: an automatic packaging device for granular materials, including a control mechanism that is arranged on a frame and is connected with a packaging mechanism set on the frame, a paper feeding mechanism and a storage mechanism, and a packaging mechanism A storage mechanism is arranged above, a paper feeding mechanism is arranged at the rear of the packaging mechanism, and an intermittent mechanism for transporting granular materials to the packaging mechanism is arranged between the storage mechanism and the packaging mechanism; the intermittent mechanism includes a movable platform 35, a guide column 36b and an intermittent mechanism. For the power module, the movable platform 35 is arranged on the frame at the packaging mechanism through the guide column 36b, and the intermittent power module is arranged above the movable platform 35 and fixedly connected with the frame. The intermittent power module is an intermi...

Embodiment 3

[0063] Embodiment three, such as Figure 3-4 , shown in 5-9, 10, 12-14: its difference with Embodiment 2 is that the intermittent mechanism includes a movable platform 35 and a hydraulic guide column 36a that doubles as an intermittent power module, and the movable platform 35 is arranged on the hydraulic guide column 36a On the frame at the packaging mechanism, the hydraulic guide column 36a drives the movable platform to move up and down through the intermittent movement of the hydraulic pump.

[0064] The method of using the invention: in the initial stage, the wrapping paper tape in the paper storage bin is driven by a stepping motor to send it into the paper feeding channel through the central controller, and the speed and length of the wrapping paper tape are controlled by the stepping motor. When the wrapping paper belt runs to the upper part of the packaging mechanism, the stepping motor stops, and at the same time triggers the intermittent mechanism to work, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com