Guide rail type separated fluid connector

A connector and rail-type technology, which is applied in the field of rail-type separated fluid connectors, can solve the problems of reduced reliability of the pipeline system, and achieve the effects of small structure, good locking effect, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

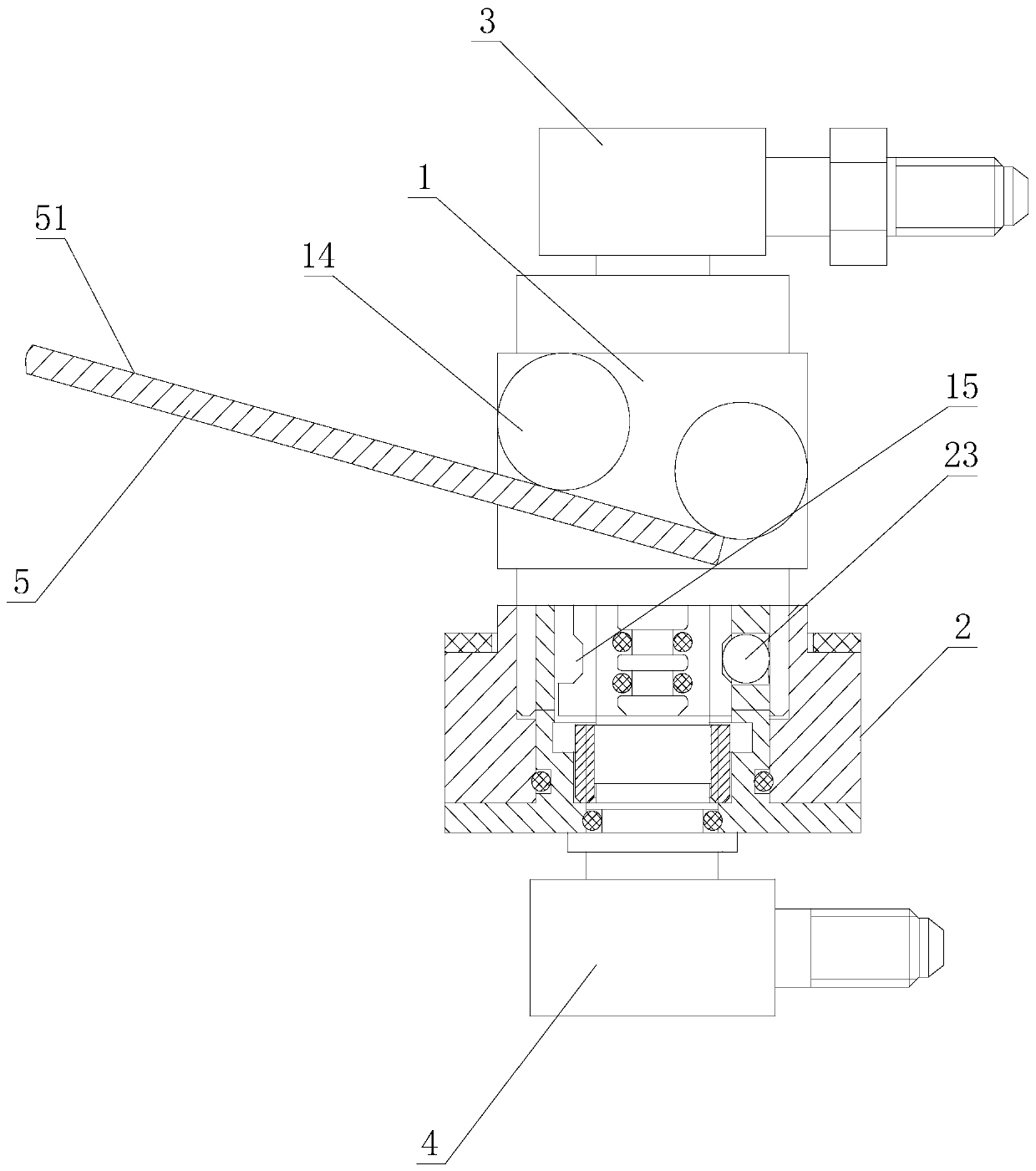

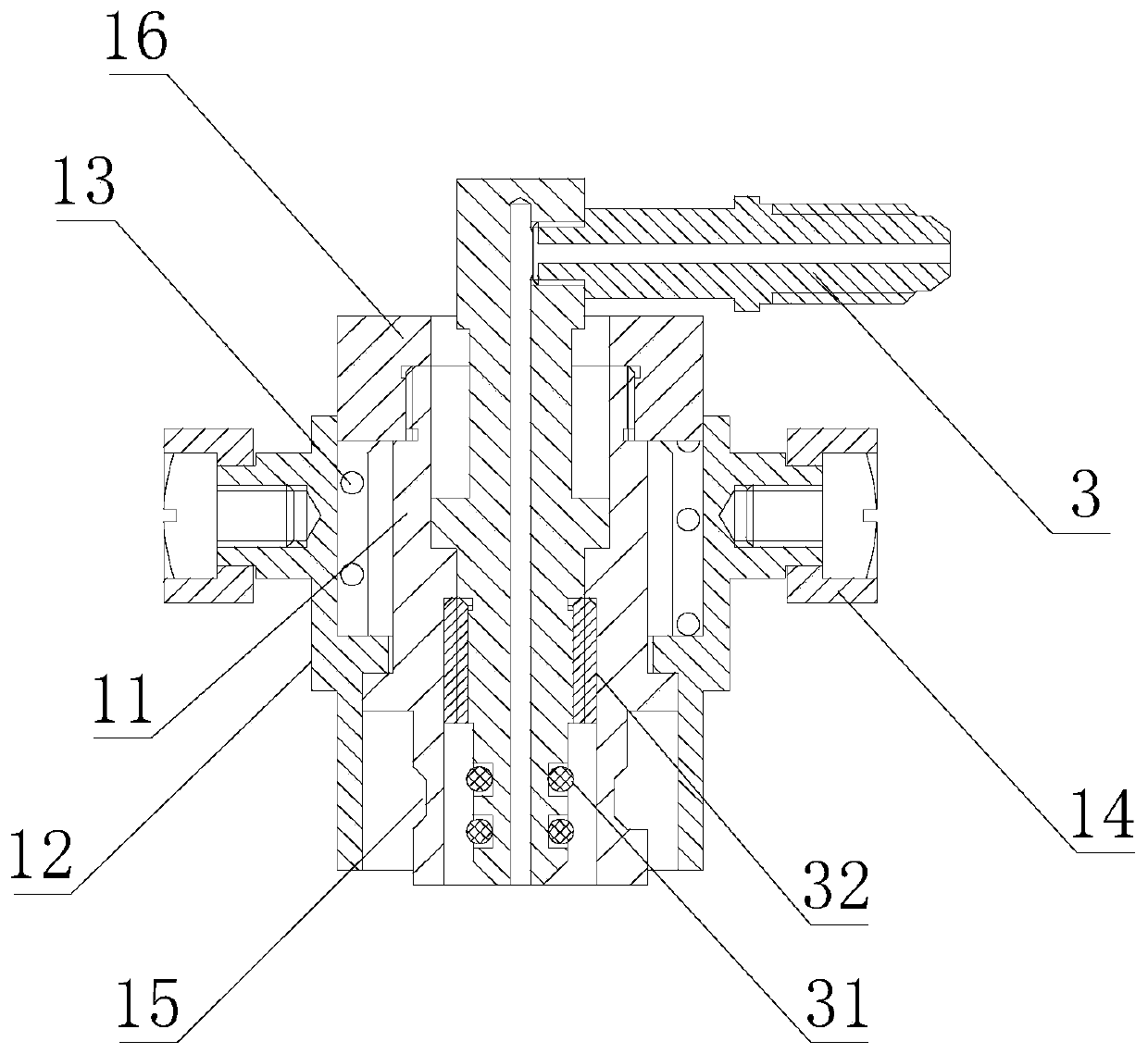

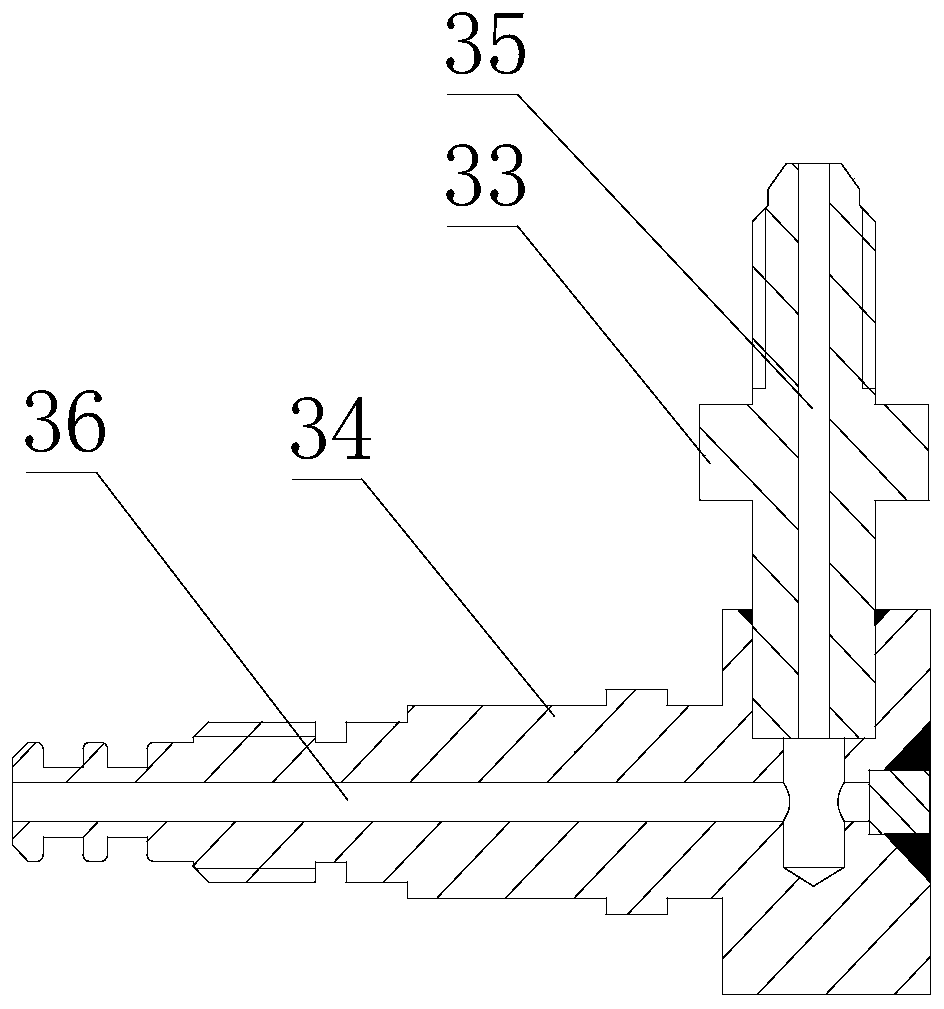

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a rail-type separated fluid connector includes a plug 1, a socket 2, a needle pipe 3, a hole pipe 4 and a guide rail 5, the plug 1 includes a connecting sleeve 11 and a pull sleeve 12, and the connecting sleeve 11 is installed in the pull sleeve 12, and a compression spring 13 is provided between the connection sleeve 11 and the pull sleeve 12. The needle pipe 3 is fixedly connected to the connection sleeve 11, and the pull sleeve 12 is provided with a Adapted roller 14, the guide rail 5 is provided with an inclined surface 51 to move the roller 14 upward, the socket 2 includes a housing 21 and a positioning sleeve 22 arranged on the housing 21, and the positioning sleeve 22 is provided with a steel The ball 23, the hole pipe 4 is fixedly connected to the positioning sleeve 22, the connecting sleeve 11 is provided with a groove 15 matching with the steel ball 23, and the needle pipe 3 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com