Overlaid-type belt pulley

A pulley, superimposed technology, applied in the direction of belt/chain/gear, components with teeth, portable lifting device, etc., can solve the problems of excessively long protruding part of the pulley, material waste, increased cost and processing time, etc., to achieve Reduce processing costs, improve processing efficiency, and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

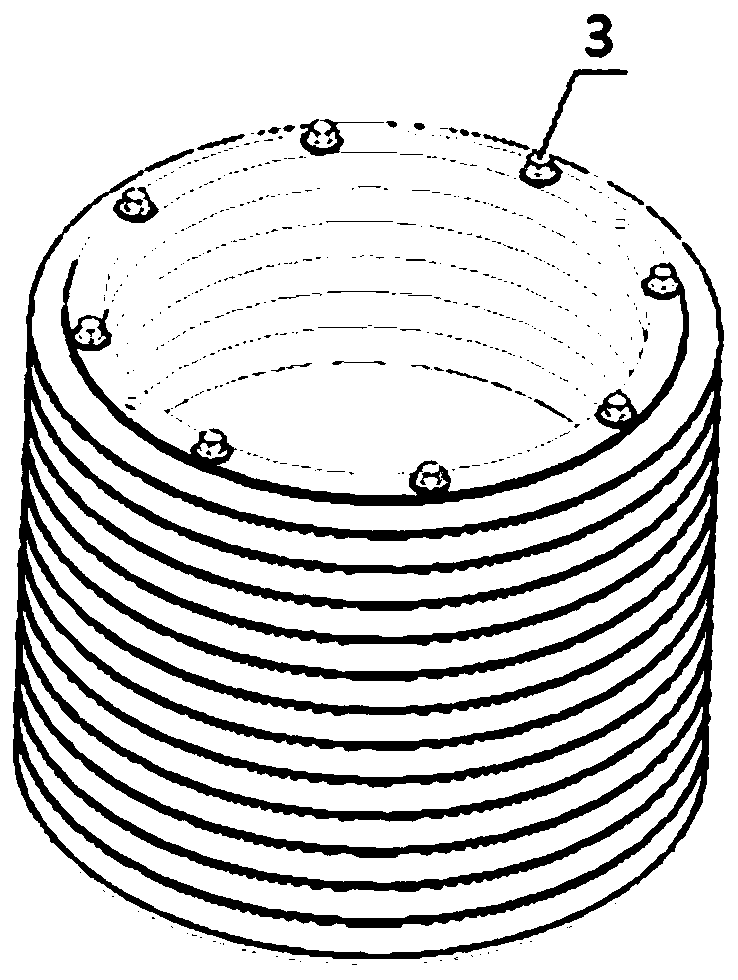

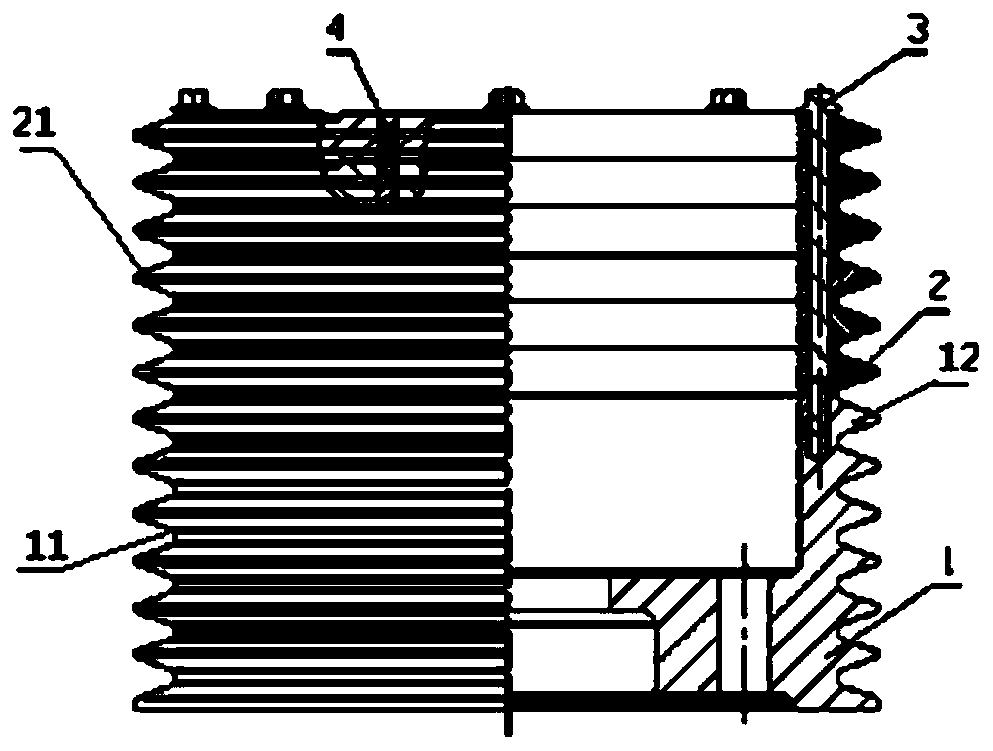

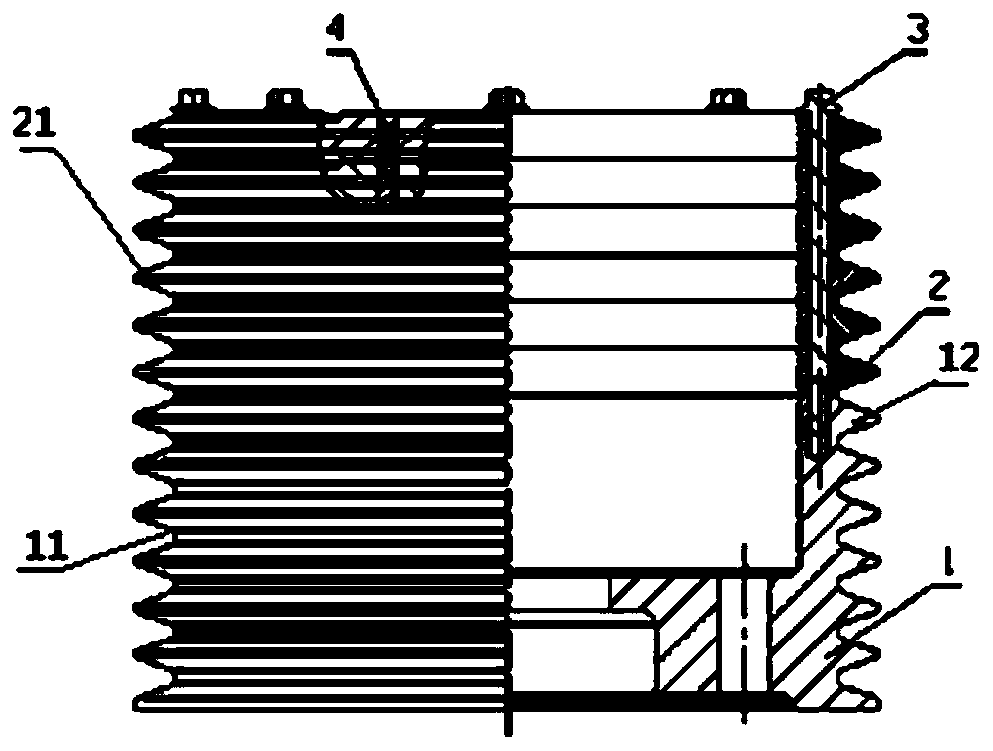

[0023] Such as Figure 1 to Figure 2 As shown, the superimposed pulley of this embodiment includes: a main pulley 1 and a plurality of auxiliary pulleys 2, and the plurality of auxiliary pulleys 2 are superimposed and arranged on the upper end surface of the main pulley 1 ( figure 2 It is shown that six auxiliary pulleys are superimposed), and the upper end surface of the outer ring of the main pulley 1 is provided with a plurality of bolt holes along the circumferential direction. The outer ring of each auxiliary pulley 2 is processed with a convex portion 21, the outer ring of each auxiliary pulley 2 is provided with a plurality of through holes in the circumferential direction, and the plurality of auxiliary pulleys 2 are fixedly connected with the main pulley 1 by bolts 3. Among them, the main pulley 1 and each auxiliary pulley 2 are provided with two positioning holes for installing positioning pins 4, so that the main pulley 1 and the auxiliary pulley 2 can be positioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com