Immobilized enzyme pickering emulsion reaction system and application thereof

A Pickering emulsion and immobilized enzyme technology, which is applied in the construction and application field of the immobilized enzyme Pickering emulsion reaction system, can solve the problem of reducing the contact area between the enzyme and the substrate, difficult product separation and purification, and not suitable for food-grade products and other problems, to shorten the distance between the reactants and the enzyme, easy to separate and purify, and easy to reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

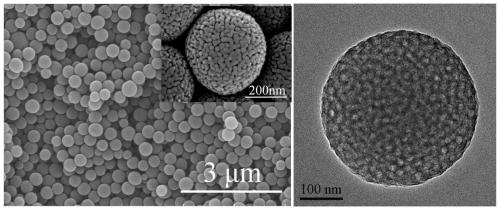

Embodiment 1

[0032] An immobilized enzyme Pickering emulsion reaction system, comprising mesoporous nano-carbon sphere immobilized enzyme, oil phase and water phase constituting the emulsion, the particle size of the emulsion is 10-80 μm, and it uses phytosterol, oleic acid ( Phytosterol, oleic acid mass ratio is 1:4) as the oil phase, 0.05M pH=6.5 sodium phosphate buffer solution (PBS) as the water phase, mesoporous nano carbon sphere immobilized enzyme as catalyst and emulsifier; wherein, mesoporous The mass ratio of nano-carbon sphere immobilized enzyme, reaction raw material and phosphate buffer solution is 0.025g: 1g: 0.1g; the particle diameter of carrier mesoporous nano-carbon sphere is 270-320nm, and the specific surface area is 580-700m 2 / g, the pore size of mesopores is 8-14nm, and the immobilized amount of enzyme on the carrier is 100mg / g.

[0033] The preparation method of above-mentioned immobilized enzyme Pickering emulsion reaction system, it comprises the steps:

[0034] ...

Embodiment 2

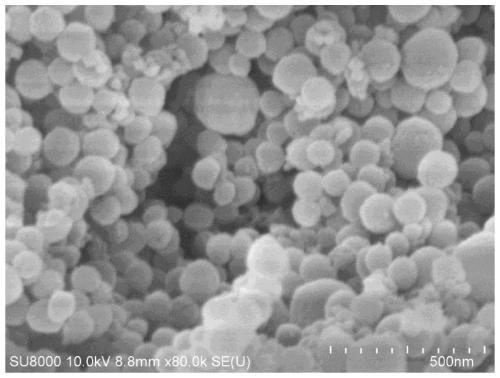

[0041] An immobilized enzyme Pickering emulsion reaction system, which consists of mesoporous nano-silicon sphere immobilized enzyme, oil phase and water phase constituting the emulsion. The particle size of the emulsion is 10-80 μm. It uses phospholipid and conjugated linoleum as reaction materials Ethyl linoleate (the mass ratio of phospholipids to ethyl conjugated linoleate is 1:4) is used as the oil phase, 0.3M sodium phosphate buffer solution (PBS) with pH=6 is used as the water phase, and mesoporous mesoporous nano-silica spheres are immobilized The enzyme is used as a catalyst and emulsifier; wherein, the mass ratio of mesoporous nano-silica sphere immobilized enzyme, reaction raw material and phosphate buffer solution is 0.05g: 1g: 0.2g; the particle diameter of carrier mesoporous nano-carbon sphere is 200-350nm , the specific surface area is 180~300m 2 / g, the pore size of mesopores is 8-14nm, and the immobilized amount of enzyme on the carrier is 300mg / g.

[0042] T...

Embodiment 3

[0051] An immobilized enzyme Pickering emulsion reaction system, which consists of mesoporous nano-titanium ball immobilized enzyme, oil phase and water phase constituting the emulsion. The particle size of the emulsion is 10-80 μm. It uses vinyl acetate and 1- Phenylethyl alcohol (the molar ratio of vinyl acetate to 1-phenylethyl alcohol is 4:1) is used as the oil phase, 0.05M pH=8 sodium phosphate buffer solution (PBS) is used as the water phase, and the enzyme immobilized by mesoporous nano-titanium spheres is used as the catalyst and emulsified agent; wherein, the mass ratio of mesoporous nano-titanium sphere immobilized enzyme, reaction raw material and phosphate buffer solution is 0.05g: 4.66g: 0.428g; the particle diameter of carrier mesoporous nano-titanium sphere is 200-350nm, and the specific surface area is 100 ~200m 2 / g, the pore size of the mesopore is 8-14nm, and the immobilized amount of the enzyme on the carrier is 200mg / g.

[0052] The preparation method of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com