Titanium dioxide composite filler, preparation method thereof and reflective heat insulation coating

A technology of reflective thermal insulation coating and titanium dioxide, which is applied in the field of coatings, can solve the problems of affecting thermal insulation effect, low film coating rate, waste of titanium dioxide, etc., and achieve excellent adhesion, increase emissivity, and improve reflective thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a kind of preparation method of titanium dioxide composite filler, comprises the following steps:

[0032] The hollow glass microsphere suspension is mixed with a modifying agent for modification to obtain activated modified hollow glass microspheres, and the modifying agent is hydrofluoric acid, sodium hydroxide, potassium hydroxide, saturated calcium hydroxide, ten Hexaalkyltrimethylammonium bromide or sodium dodecylbenzenesulfonate;

[0033] Provide titanium tetrachloride ethanol solution;

[0034] After mixing the activated modified hollow glass microspheres with water, adjusting the pH value to 2-4 and heating successively to obtain a suspension;

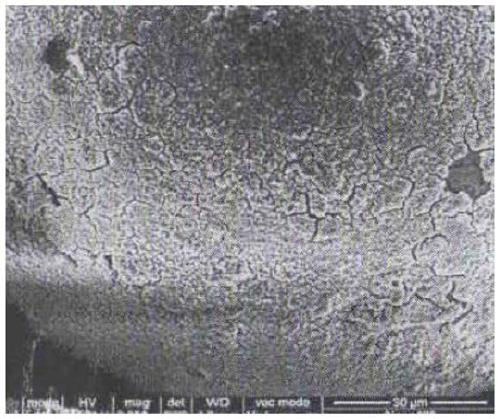

[0035] After the titanium tetrachloride ethanol solution is added dropwise to the suspension, it is allowed to stand and age to obtain microspheres wrapped in titanium dioxide microcrystals;

[0036] The microspheres wrapped by the titanium dioxide microcrystals are dried and calcined in sequence...

Embodiment 1

[0069] 1. Preparation of titanium dioxide composite filler

[0070] Get 40g of hollow glass microspheres and add 120g of deionized water to prepare a suspension with a mass concentration of 25%, add hydrofluoric acid with a mass concentration of 10%, and stir at 150r / min for 100min; Bake at 120°C for 120 minutes; bake at 80°C for 300 minutes; finally bake at 120°C for 16 hours to obtain activated-modified hollow glass microspheres with a particle size of 65 μm;

[0071] Under stirring at 300r / min, slowly add 30g of titanium tetrachloride into 70mL of absolute ethanol to prepare a 100g / L titanium tetrachloride ethanol solution.

[0072]Prepare the activated modified hollow glass microspheres into a 25% suspension; add hydrochloric acid to adjust the pH value of the suspension to 2; Add one-third of the titanium tetrachloride ethanol solution at a dropping speed; then add one-third of the titanium tetrachloride ethanol solution at a stirring speed of 10g / min at a stirring speed...

Embodiment 2

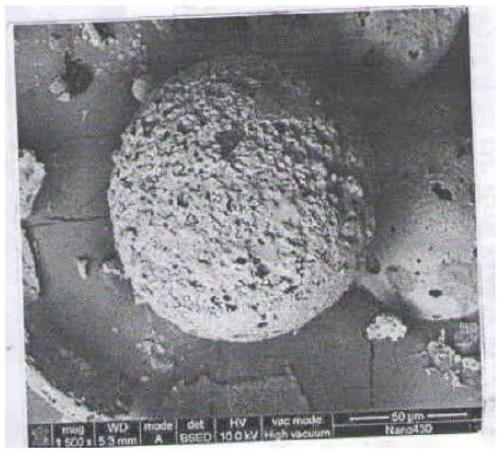

[0083] 1. Preparation of titanium dioxide composite filler

[0084] Take 50g of hollow glass microspheres and add 150g of deionized water to prepare a suspension with a mass concentration of 25%, add NaOH with a mass concentration of 10%, and stir at 150r / min for 100min; put it in an oven for drying, first at 55°C Bake for 120 minutes; bake at 80°C for 300 minutes; finally bake at 120°C for 16 hours to obtain activated modified hollow glass microspheres with a particle size of 50 μm;

[0085] Under stirring at 300r / min, slowly add 30g of titanium tetrachloride into 170mL of absolute ethanol to prepare a 200g / L titanium tetrachloride ethanol solution.

[0086] Prepare the activated modified hollow glass microspheres into a 25% suspension; add hydrochloric acid to adjust the pH value of the suspension to 3; Add one-third of the titanium tetrachloride ethanol solution at a dropping speed; then at a stirring speed of 200r / min, add one-third of the titanium tetrachloride ethanol s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com