A mobile phone case with excellent heat dissipation and preparation method thereof

A mobile phone case and heat dissipation technology, applied in the field of mobile phone case and its preparation, can solve the problems of easy deformation and wear resistance, poor radiation protection effect and high processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

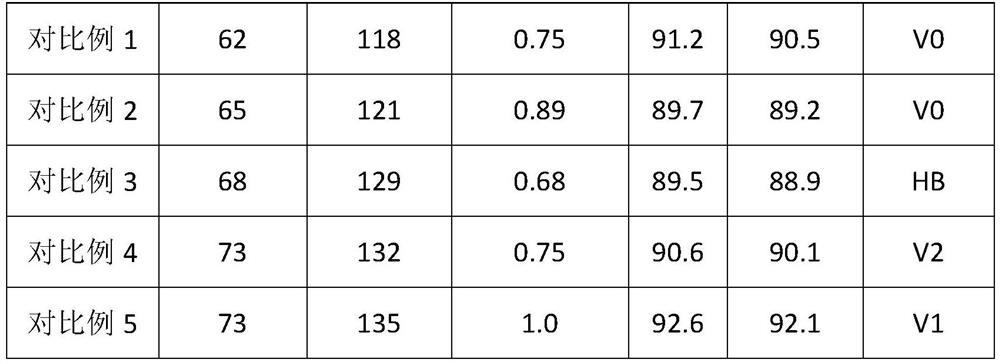

Examples

Embodiment 1

[0025] A mobile phone casing with excellent heat dissipation provided by this embodiment is an organic-inorganic composite material, and its raw materials include the following components by weight: polycarbonate 32.5kg, ultra-high molecular weight polyethylene 9kg, nano-aluminum nitride Fiber 2.5kg, bismuth trioxide 2kg, modified expandable graphite 2.5kg, magnesium borate whisker 1.5kg. Wherein, the molecular weight of the ultra-high molecular weight polyethylene is not less than 1.8 million; the bismuth trioxide is δ-type bismuth trioxide.

[0026] The modified expandable graphite is expanded graphite modified by boric acid and simethicone, and its specific preparation method is: first disperse 3.5kg of expandable graphite with 35kg of ethanol, and then add 35g of simethicone Stir, then add 70g of boric acid, disperse with ultrasonic wave for 60min, filter and dry to obtain the modified expandable graphite.

[0027] In addition, the above-mentioned method for preparing a m...

Embodiment 2

[0033] A mobile phone casing with excellent heat dissipation provided by this embodiment is an organic-inorganic composite material, and its raw materials include the following components by weight: 20 kg of polycarbonate, 12.5 kg of ultra-high molecular weight polyethylene, and nano-aluminum nitride Fiber 5kg, bismuth trioxide 4kg, modified expandable graphite 5kg, magnesium borate whisker 3.5kg. Wherein, the molecular weight of the ultra-high molecular weight polyethylene is not less than 1.8 million; the bismuth trioxide is δ-type bismuth trioxide.

[0034] The modified expandable graphite is expanded graphite modified by boric acid and simethicone, and its specific preparation method is: first disperse 3.5kg of expandable graphite with 35kg of ethanol, and then add 35g of simethicone Stir, then add 70g of boric acid, disperse with ultrasonic wave for 60min, filter and dry to obtain the modified expandable graphite.

[0035] In addition, the above-mentioned method for prep...

Embodiment 3

[0041]A mobile phone casing with excellent heat dissipation provided by this embodiment is an organic-inorganic composite material, and its raw materials include the following components in parts by weight: 29 kg of polycarbonate, 15 kg of ultra-high molecular weight polyethylene, and nano-aluminum nitride Fiber 3.5kg, bismuth trioxide 2.5kg, modified expandable graphite 3kg, magnesium borate whisker 2kg. Wherein, the molecular weight of the ultra-high molecular weight polyethylene is not less than 1.8 million; the bismuth trioxide is δ-type bismuth trioxide; the modified expandable graphite is boric acid and simethicone modified The specific preparation method of the expandable graphite is as follows: first disperse the expandable graphite with ethanol, then add simethicone for stirring, then add boric acid, disperse with ultrasonic waves, filter and dry to obtain the described modified expandable graphite.

[0042] In addition, the above-mentioned method for preparing a mob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com