POSS modified mercapto containing pentaerythritol ester crosslinked network polymer, and preparation method and applications thereof

A technology of mercaptopentaerythyl ester and cross-network, which is applied in the field of flame retardant materials, and can solve the problems of high specificity, insignificant effect, and large addition amount of flame retardant silicone rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

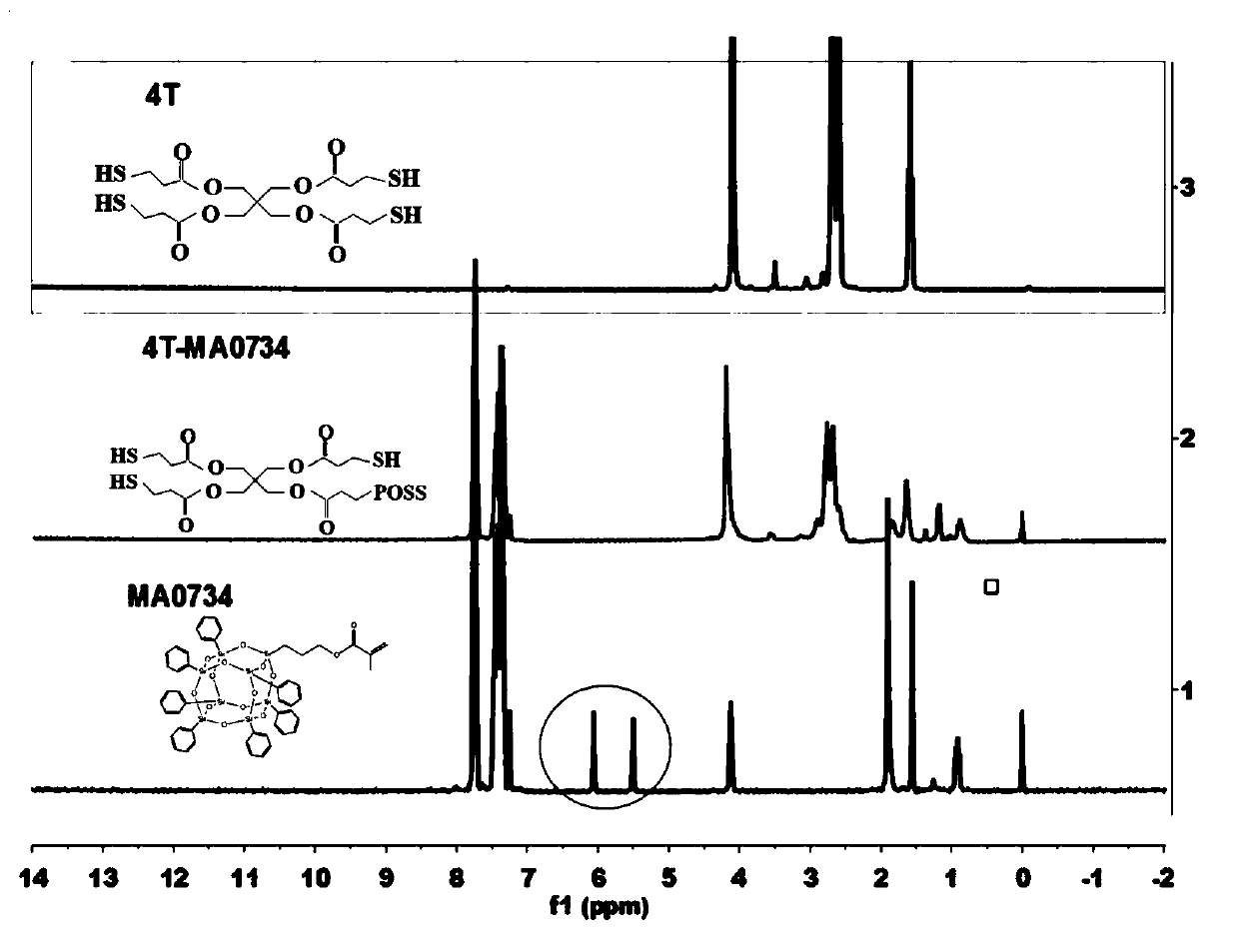

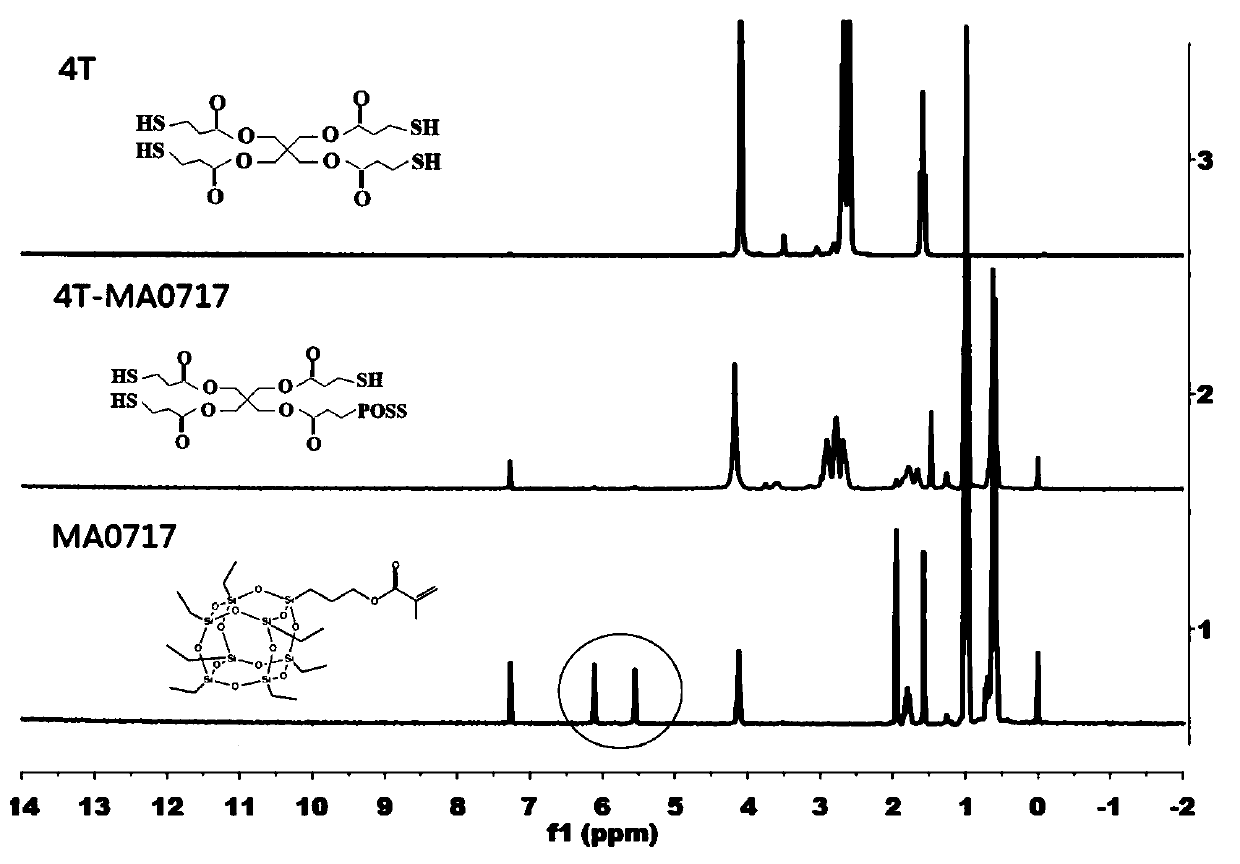

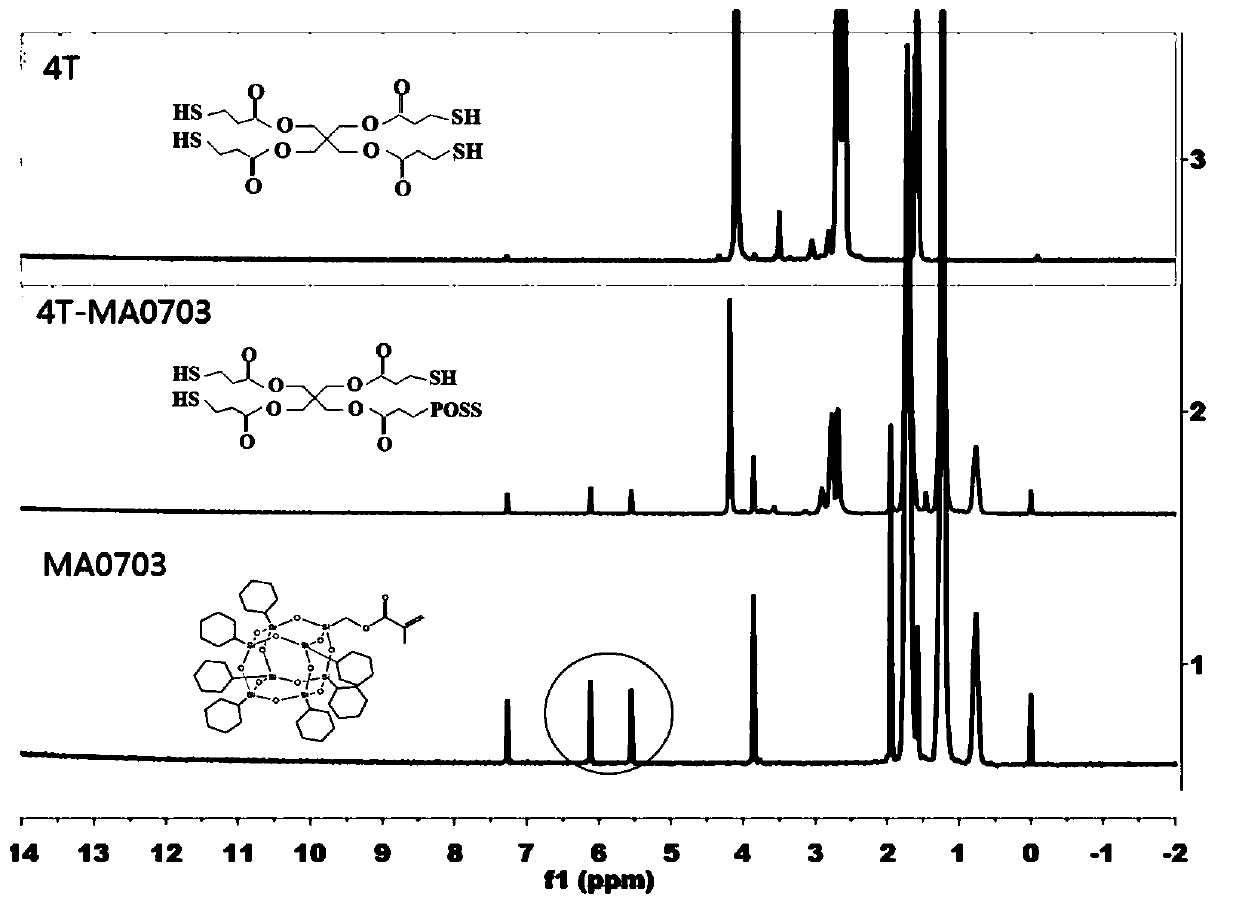

[0044] Example 1 Preparation of 4T-0.5MA0734-3T-TTT

[0045] Using acetone as a solvent, the modified additive POSS (MA0734) was completely dissolved in acetone, and added dropwise to 4T containing 0.1-2% POSS equivalent of di-n-butylamine initiator in an equimolar ratio, and stirred at room temperature for 24 hours. The molar ratio of POSS to 4T is 1:1, and the POSS-modified mercapto-pentaerythyl ester compound is prepared, and then the acetone solvent is removed by rotary evaporation to obtain a solid powder POSS-modified mercapto-containing pentaerythyl ester. Then the mercapto-pentaerythyl esters containing mercapto-pentaerythyl esters modified by 0.5% POSS are completely dissolved in acetone, and 0.2% DMPA photoinitiator and 3T and TTT containing mercapto-pentaerythyls molar equivalents are added to carry out under ultraviolet light Cross-linking, solvent removal, drying to obtain network polymer 4T-0.5MA0734-3T-TTT;

Embodiment 2

[0046] Example 2 Preparation of 4T-1MA0734-3T-TTT

[0047]Using acetone as a solvent, the modified additive POSS (MA0734) was completely dissolved in acetone, and added dropwise to 4T containing 0.1-2% POSS equivalent of di-n-butylamine initiator in an equimolar ratio, and stirred at room temperature for 24 hours. The molar ratio of POSS to 4T is 1:1, and the POSS-modified mercapto-pentaerythyl ester compound is prepared, and then the acetone solvent is removed by rotary evaporation to obtain a solid powder POSS-modified mercapto-containing pentaerythyl ester. Then the mercapto-pentaerythyl esters containing mercapto-pentaerythyl esters modified by POSS with 1% mole fraction are completely dissolved in acetone, and 0.2% DMPA photoinitiator and 3T and TTT containing mercapto-pentaerythyls molar equivalents are added to carry out under ultraviolet light Cross-linking, removing the solvent, and drying to obtain the network polymer 4T-1MA0734-3T-TTT;

Embodiment 3

[0048] Example 3 Preparation of 4T-3MA0734-3T-TTT

[0049] Using acetone as a solvent, the modified additive POSS (MA0734) was completely dissolved in acetone, and added dropwise to 4T containing 0.1-2% POSS equivalent of di-n-butylamine initiator in an equimolar ratio, and stirred at room temperature for 24 hours. The molar ratio of POSS to 4T is 1:1, and the POSS-modified mercapto-pentaerythyl ester compound is prepared, and then the acetone solvent is removed by rotary evaporation to obtain a solid powder POSS-modified mercapto-containing pentaerythyl ester. Then the mercapto-pentaerythyl esters containing mercapto-pentaerythyl esters modified by POSS with 3% mole fraction are completely dissolved in acetone, and 0.2% DMPA photoinitiator and 3T and TTT containing mercapto-pentaerythyls molar equivalents are added to carry out under ultraviolet light Cross-linking, solvent removal, and drying yielded network polymer 4T-3MA0734-3T-TTT.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com