Automatic grinding production line of touch screen glass

A touch screen and production line technology, applied in grinding machines, optical surface grinders, grinding/polishing equipment, etc., can solve the problems of low work efficiency and high labor intensity of operators, and achieve the effect of improving grinding efficiency and ensuring grinding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

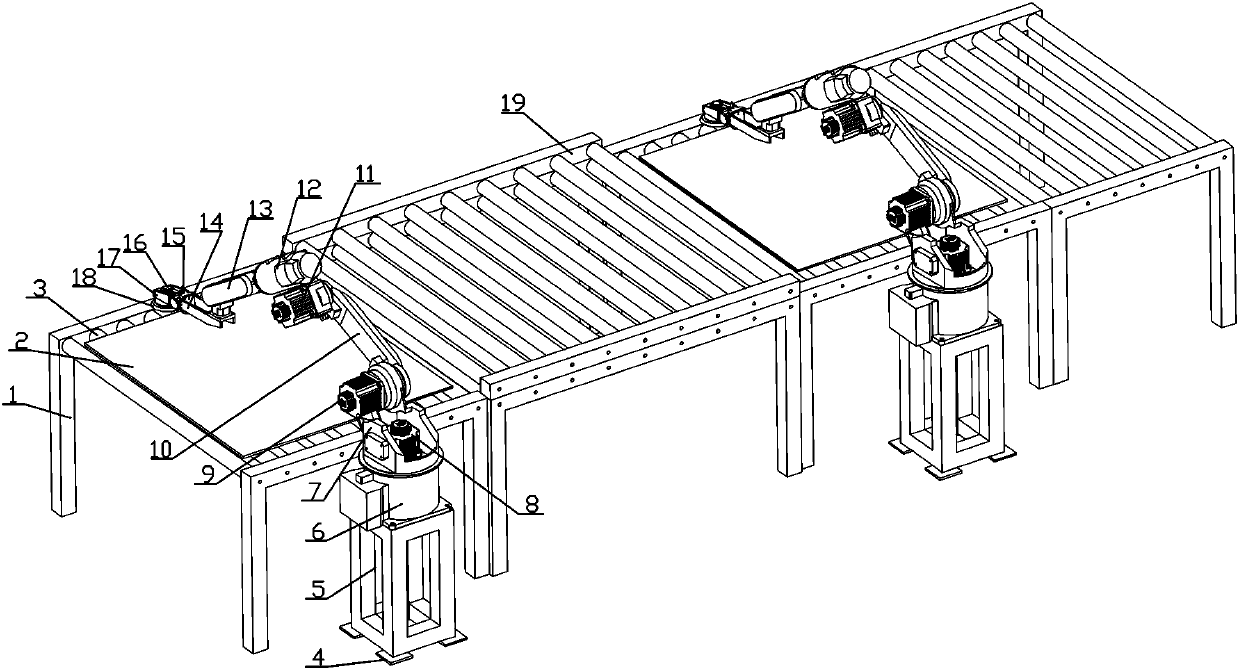

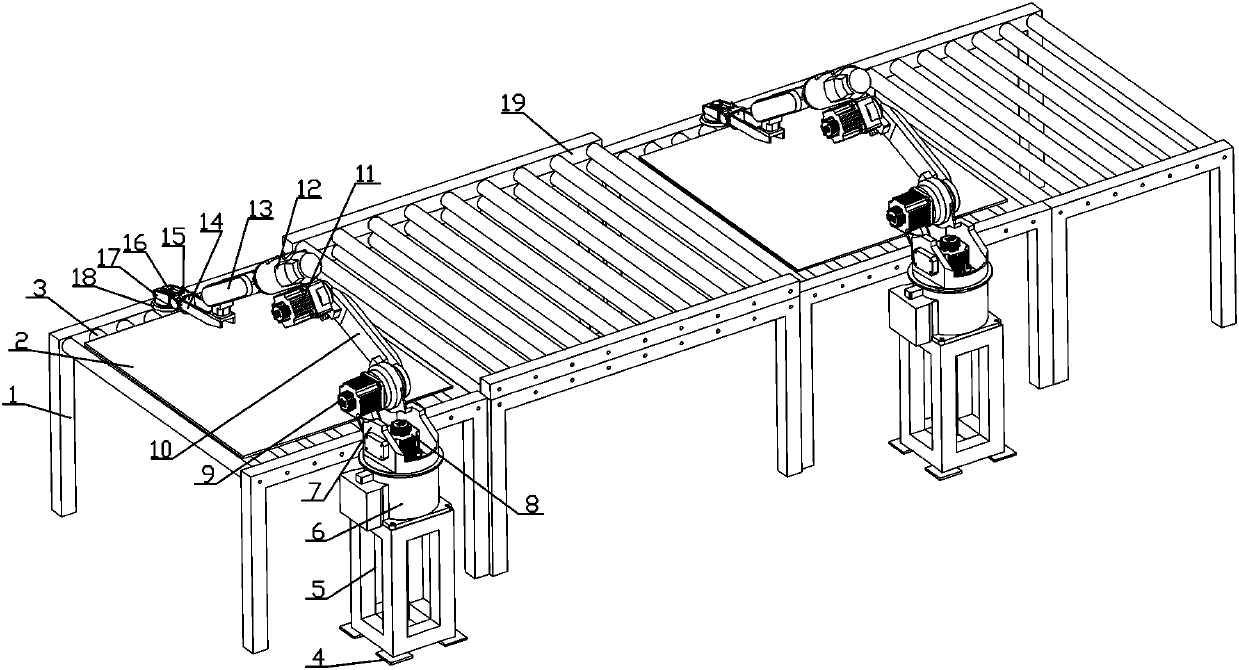

[0017] see Figure 1-2 , touch screen glass automatic polishing production line, which includes a conveyor line frame 1, the top of the conveyor line frame 1 is installed with a roller assembly 3 for conveying touch screen glass, and the side of the conveyor line frame 1 is installed with a and polished automatic grinding manipulator; a transition idler roller assembly 19 is set between two adjacent groups of conveying line racks 1, and a grinding device is installed at the end of the grinding manipulator. during work, through

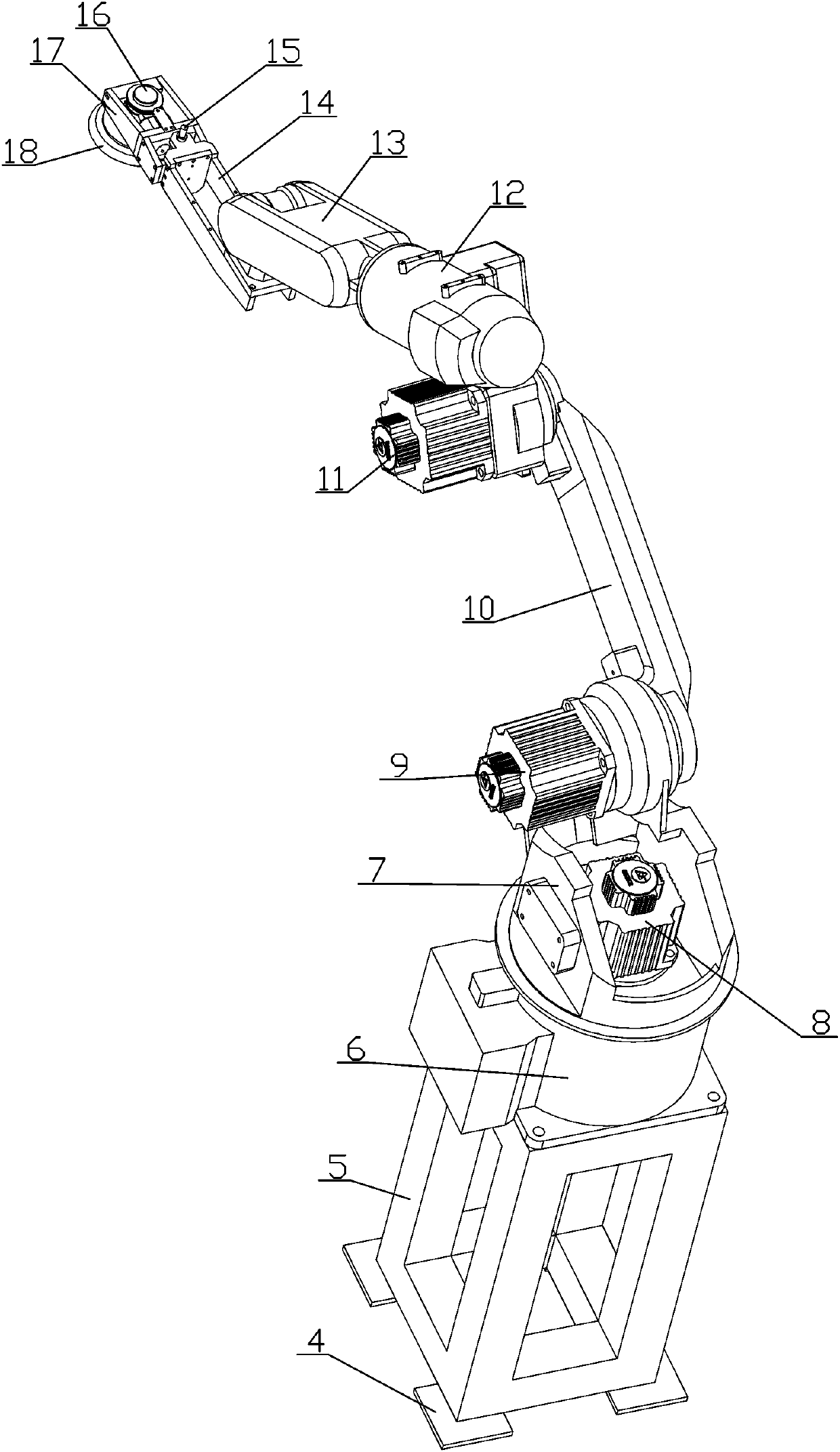

[0018] Further, the automatic polishing manipulator includes a support frame 5, the support frame 5 is fixedly installed on the base plate 4, a rotating support base 6 is installed on the bottom of the support frame 5, and a rotating chassis is installed on the rotating support base 6 7. The rotating chassis 7 cooperates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com