Graph on-line splicing method and system for laser processing of large format

A laser processing and splicing system technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problem that the splicing accuracy of processing graphics cannot meet the processing requirements, and achieve saving splicing costs, reducing performance indicators, and ensuring splicing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the content of the present invention is described in further detail:

[0036] The invention provides a method and system for on-line splicing of graphics for large-format laser processing. The method and system ensure the splicing accuracy of large-format laser scanning graphics and provide guarantee for high-precision and precise laser scanning.

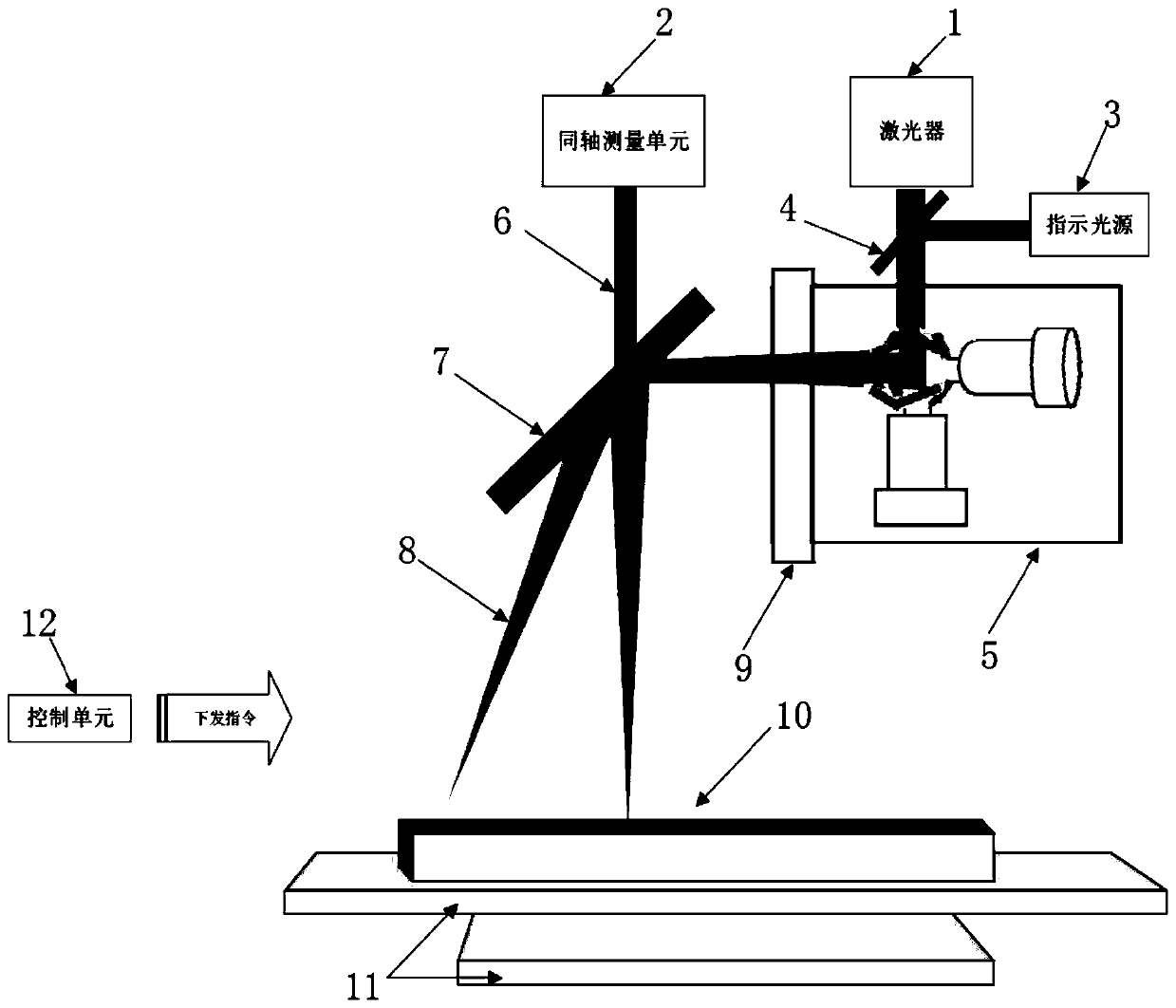

[0037] Such as figure 1 As shown, the graphics online stitching system for large-format laser processing includes an indicator light source 3, a first mirror 4, a second mirror 7, a scanning galvanometer 5, a focusing unit 9, a coaxial measurement unit 2 and a control unit 12 The scanning galvanometer 5 realizes the deflection of the beam at any angle through its built-in two reflectors, so as to realize the scanning of the beam at any position on the workpiece surface; the beam emitted by the laser 1 passes through the scanning galvanometer 5, the focusin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com