Welding slag sweeping roller for processing of electronic circuit board

A technology for electronic circuit boards and cleaning rollers, which is applied to the cleaning method using tools, non-electric welding equipment, metal processing equipment, etc., can solve the problems of welding slag falling into the machine, the impact of sonic welding, and damage to the machine, etc., to improve cleaning effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

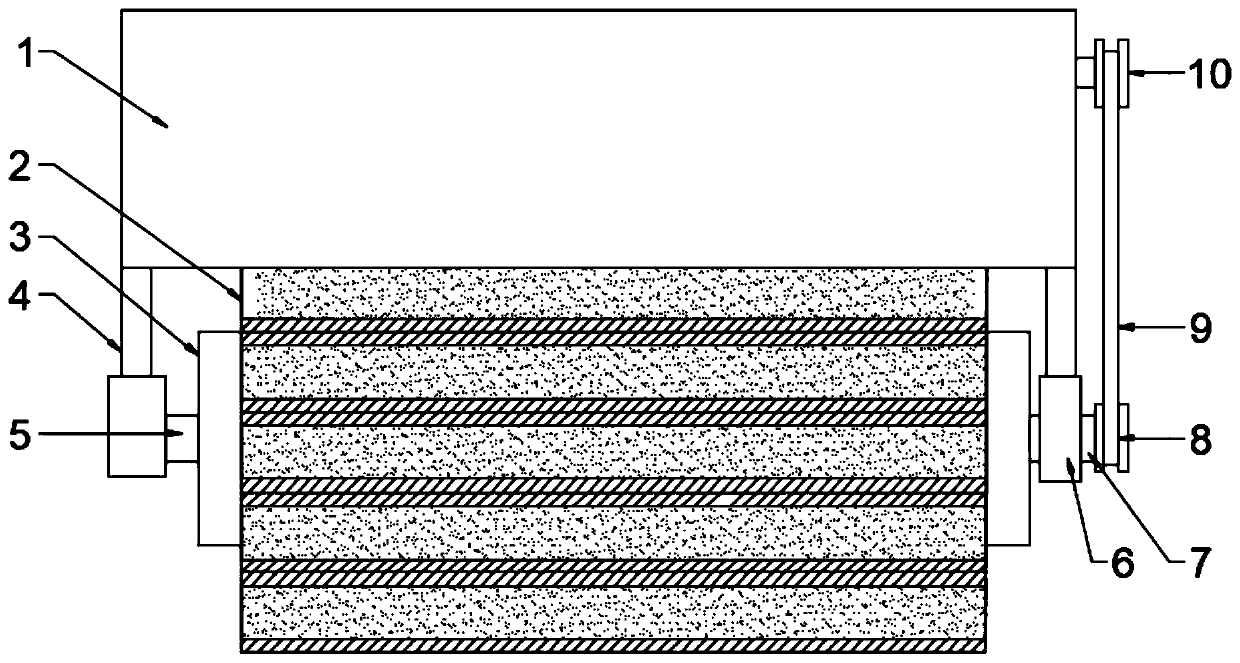

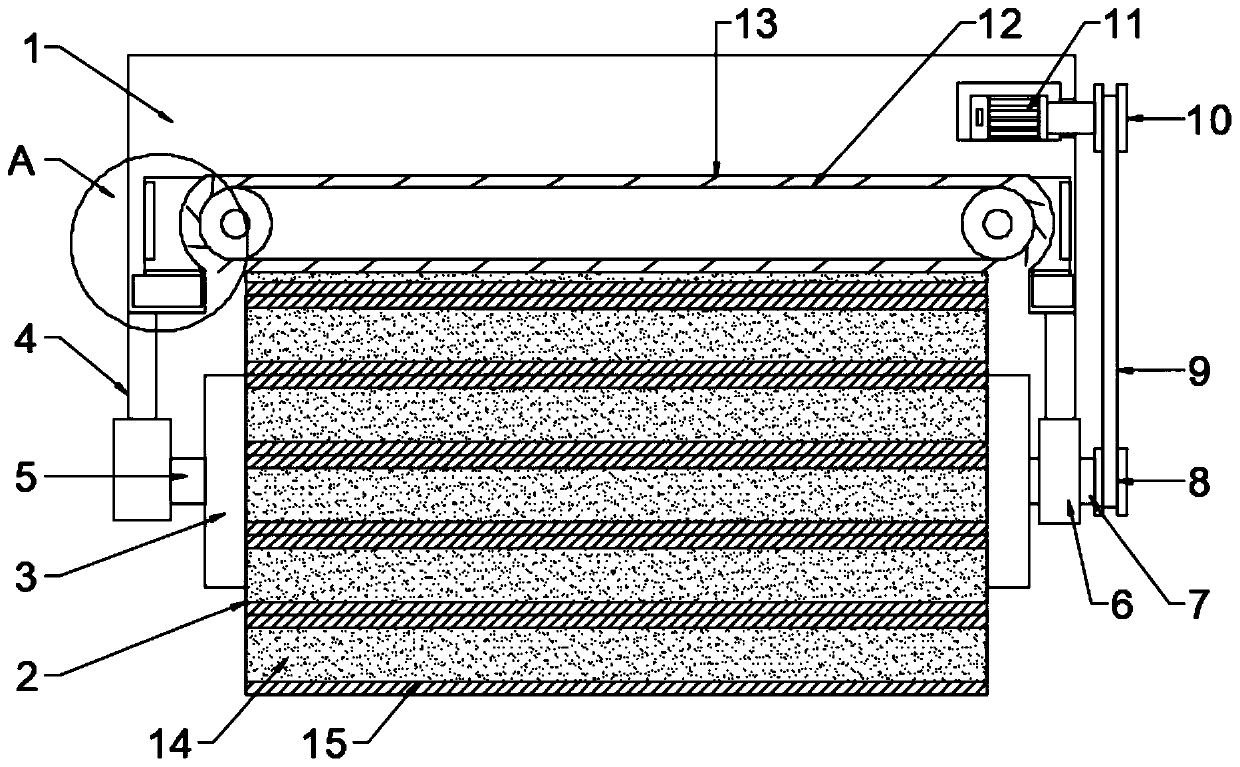

[0025] see figure 1 with figure 2 , in an embodiment of the present invention, a welding slag cleaning roller for electronic circuit board processing includes an outer fixed shell 1, and a roller body 2 is installed at the lower end of the outer fixed shell 1. In order to clean up the welding slag, the roller body 2 is There are fixed magnet plates 14 distributed at equal intervals. In order to improve the cleaning effect of welding slag, brush strips 15 are fixed on the roller bodies 2 on both sides of the magnet plate 14, and bristles are laid on the brush strips 15 to avoid excessive adsorption of the magnet plates 14. Welding slag further affects the adsorption effect. A conveyor belt 12 is installed inside the outer fixed shell 1. Arrayed scrapers 13 are welded on the conveyor belt 12. The angle between the scrapers 13 and the conveyor belt 12 is set at 60 degrees.

[0026] Further, the first rotating shaft 5 is fixed on the left end of the roller body 2, the second rot...

Embodiment 2

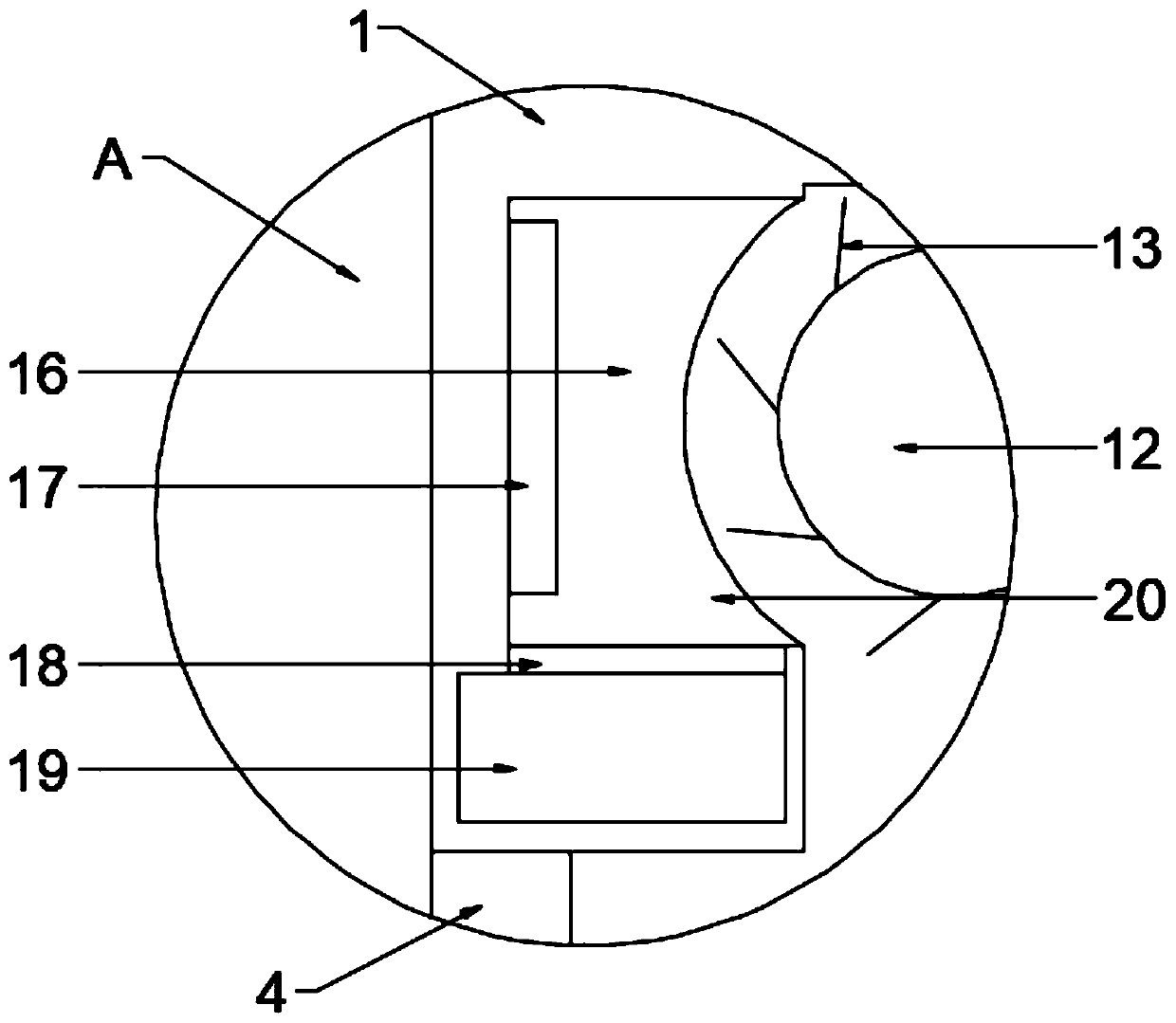

[0028] A welding slag cleaning roller for electronic circuit board processing, please refer to figure 2 with image 3 , the embodiment of the present invention is on the basis of embodiment 1, and further, a slag storage box 20 is installed inside the outer fixed shell 1 in conjunction with the conveyor belt 12, and a cavity 16 is arranged inside the slag storage box 20, and the cavity 16 is fixed inside A magnet block 17 is arranged, and a storage box 19 is provided at the lower end of the cavity 16, and a slag discharge pipe is installed on the storage box 19, and a through hole 18 is provided between the storage box 19 and the cavity 16.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com