Heat insulation pad with conduction and heat radiation effects

A technology of heat dissipation and heat insulation pads, which is applied in the field of kitchen utensils, and can solve problems such as easy wear, inconvenient movement and taking, and inconvenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

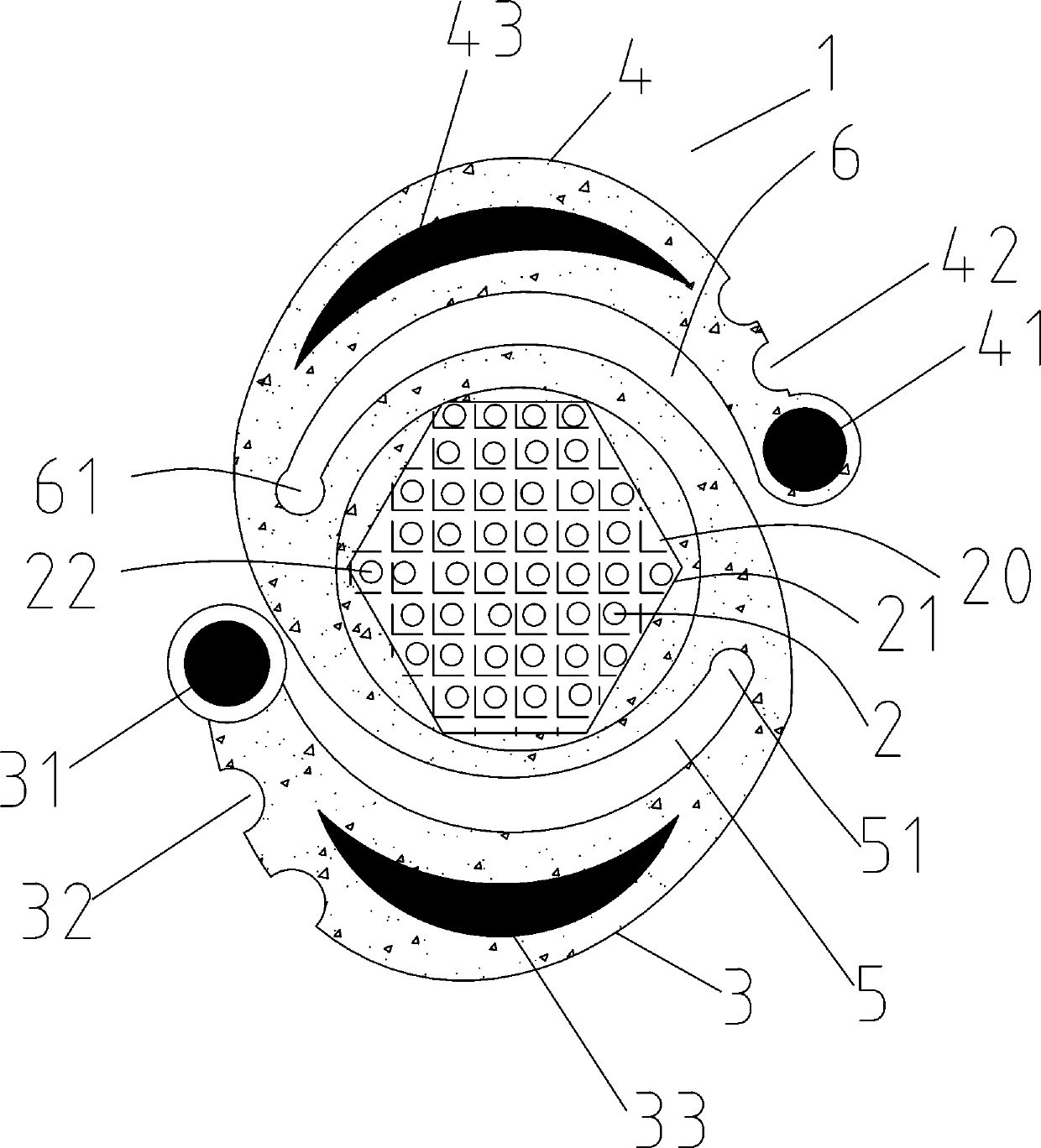

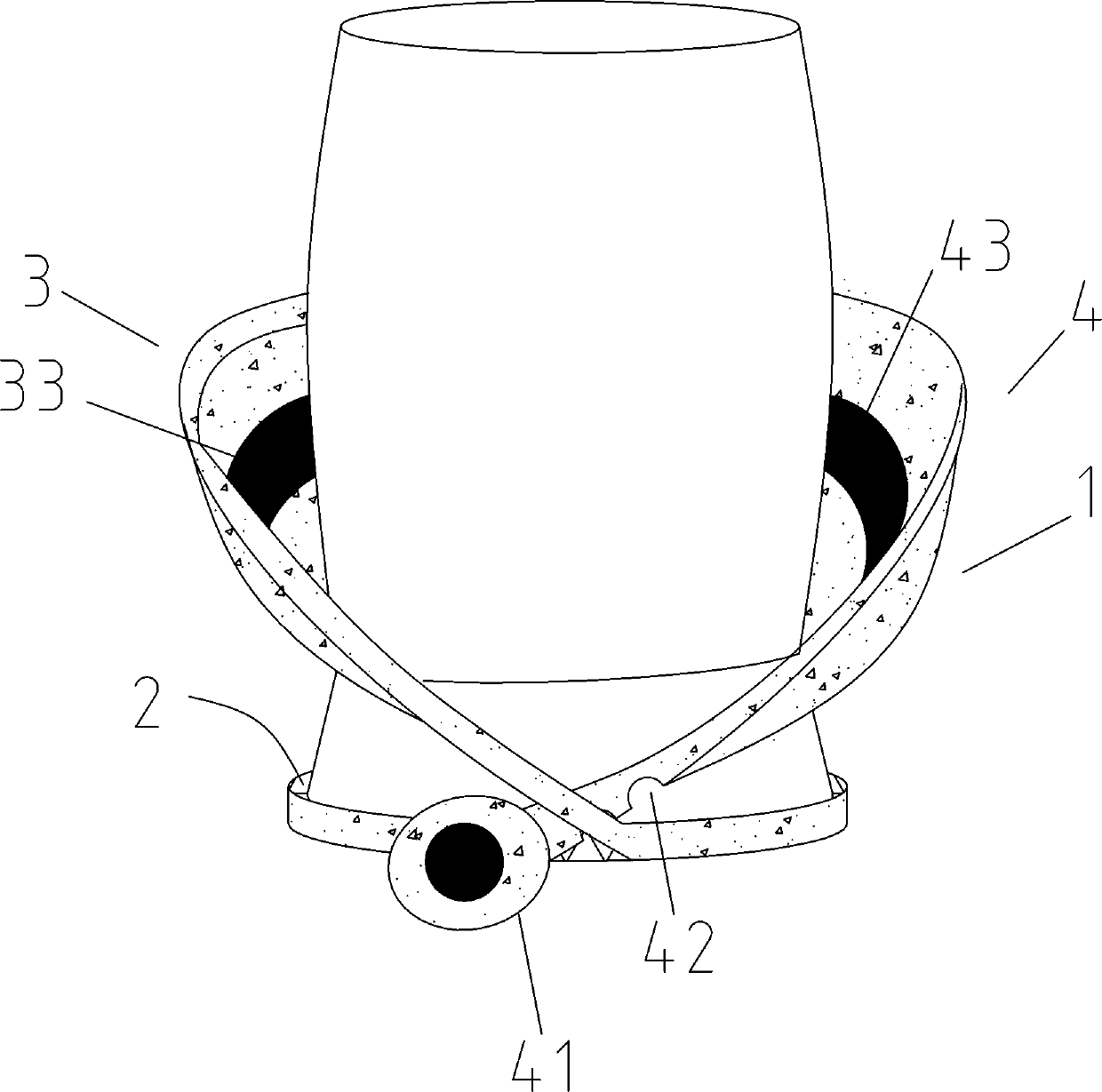

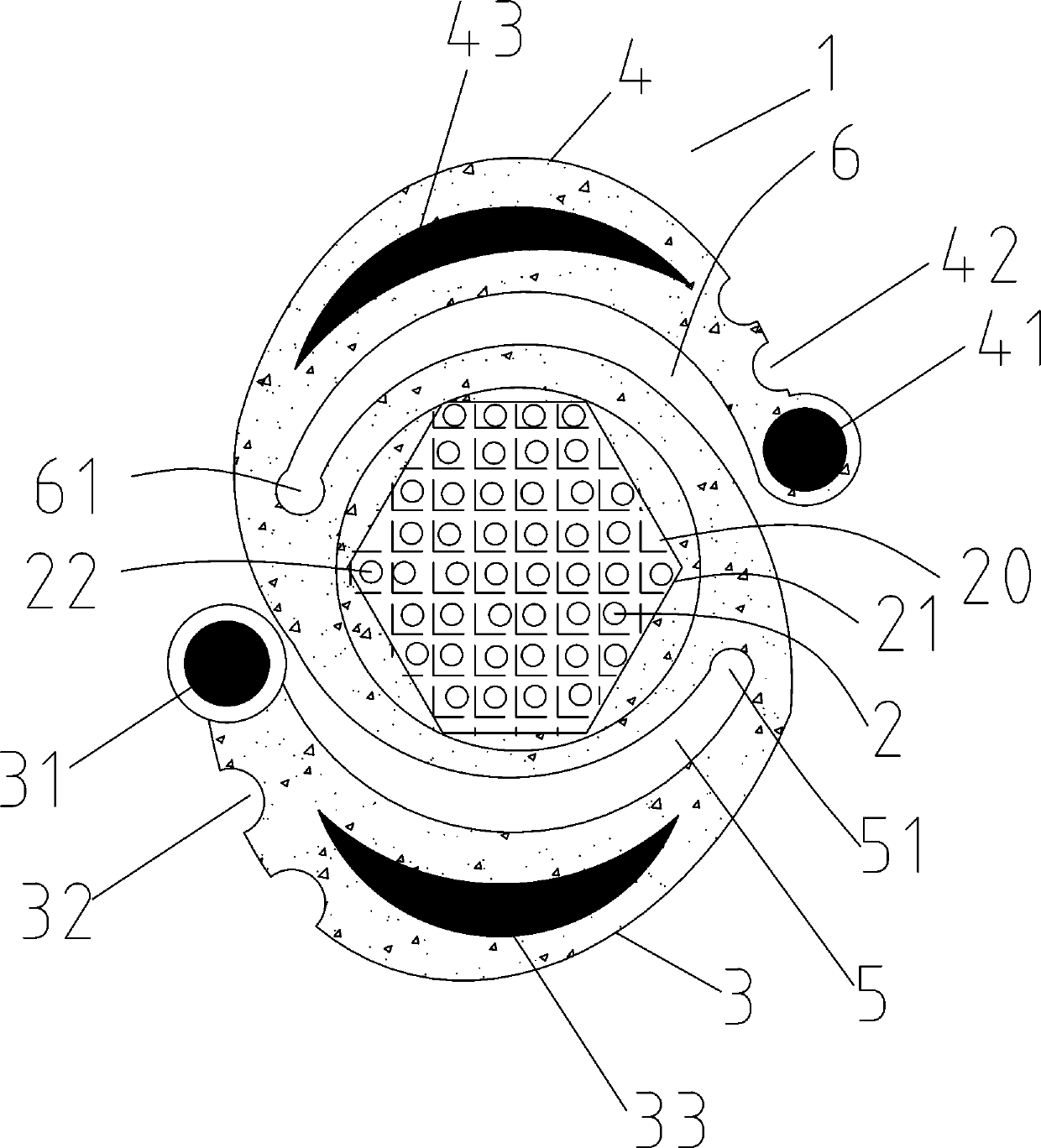

[0021] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0022] Such as Figure 1~2 As shown, it is a structural schematic diagram of a preferred embodiment of the present invention, specifically a heat insulation pad with conduction and heat dissipation, including a heat insulation bottom plate 2, and a defined cavity 20 is arranged in the middle of the heat insulation bottom plate 2, and the defined cavity 20 is fixedly arranged There is a heat-conducting support grid 21 matching the shape of the defined cavity 20, the heat-conducted support grid 21 is a metal grid frame, and an accommodation cavity is formed between the heat-conducting support grid 21 and the defined cavity 20, and a metal bump 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com