Composite current collector with electrical interconnection and through-hole structure, preparation method thereof, battery pole pieces and lithium ion battery

A current collector and electrical interconnection technology, applied in battery electrodes, electrode current collector coatings, electrode carriers/current collectors, etc., can solve the incompatibility of laminated welding processes, the inability of welding strength and overcurrent area to be guaranteed, and the deterioration of batteries. performance and other issues, to achieve the effect of improving current distribution and power output capability, ensuring welding strength and overcurrent area, and improving capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

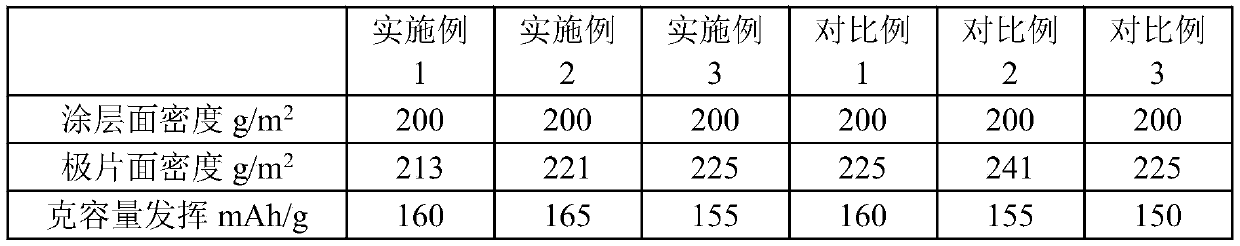

Embodiment 1

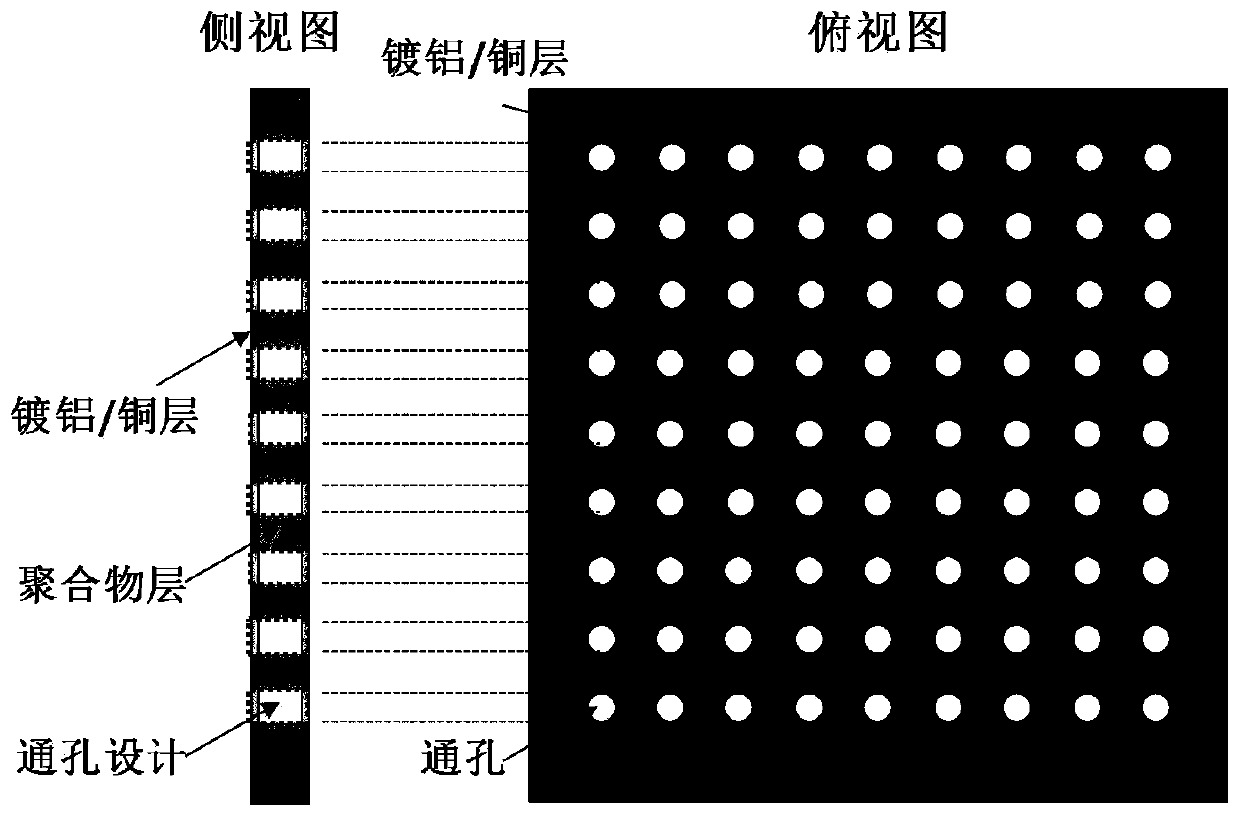

[0035]Put the 5μm PET film layer in the vacuum metallization device, under the vacuum state, the aluminum metal is heated and melted until it evaporates, and the aluminum atoms condense on the surface of the PET film layer to form an extremely thin aluminum layer. By precisely controlling the PET film take-up speed to 500m / min, while controlling the aluminum feeding speed to 0.3m / min@2mm aluminum wire and the heating current of the evaporation boat, a metal coating with a thickness of 0.1μm is obtained on the surface of the PET film. Using CO 2 A laser generator creates holes. Specifically, 10.6μm CO with 500W high pulse intensity was selected. 2 The laser uses the high intensity of the laser pulse to cause the local heating and melting of the PET film layer to obtain a through hole with a diameter of 1mm. At the same time, the scanning mirror system is used to flexibly select the distance between the holes to 2mm. The obtained through-hole PET film layer is placed in a vac...

Embodiment 2

[0040] The 8μm PET film layer is placed in a vacuum metallization device. In a vacuum state, the aluminum metal is heated and melted until it evaporates, and the aluminum atoms condense on the surface of the PET film layer to form an extremely thin aluminum layer. By precisely controlling the PET film take-up speed to 400m / min, while controlling the aluminum feeding speed to 0.2m / min@2mm aluminum wire and the heating current of the evaporation boat, a metal coating with a thickness of 0.1μm is obtained on the surface of the PET film. Using CO 2 A laser generator creates holes. Specifically, 10.6μm CO with 300W high pulse intensity was selected. 2 The laser uses the high intensity of the laser pulse to cause the local heating and melting of the PET film layer to obtain a through hole with a diameter of 0.3mm. At the same time, the scanning mirror system is used to flexibly select the distance between holes to 3mm. The obtained through-hole PET film layer is placed in a vacuu...

Embodiment 3

[0045] The 10μm PET film layer is placed in a vacuum metallization device. In a vacuum state, the aluminum metal is heated and melted until it evaporates, and the aluminum atoms condense on the surface of the PET film layer to form an extremely thin aluminum layer. By precisely controlling the PET film take-up speed to 300m / min, while controlling the aluminum feeding speed to 0.3m / min@2mm aluminum wire and the heating current of the evaporation boat, a metal coating with a thickness of 0.2μm is obtained on the surface of the PET film. Using CO 2 A laser generator creates holes. Specifically, 10.6μmCO with 500W high pulse intensity was selected 2 The laser uses the high intensity of the laser pulse to cause the local heating and melting of the PET film layer to obtain a through hole with a diameter of 0.5mm. At the same time, the scanning mirror system is used to flexibly select the distance between the holes to 4mm. The obtained through-hole PET film layer is placed in a va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com