Tension sensor static calibration device and method in weightless environment

A tension sensor, static calibration technology, applied in the direction of measuring devices, instruments, force/torque/power measuring instrument calibration/testing, etc., can solve the problem that the traditional calibration method is no longer applicable, achieve accurate calibration, and avoid the effect of weightlessness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

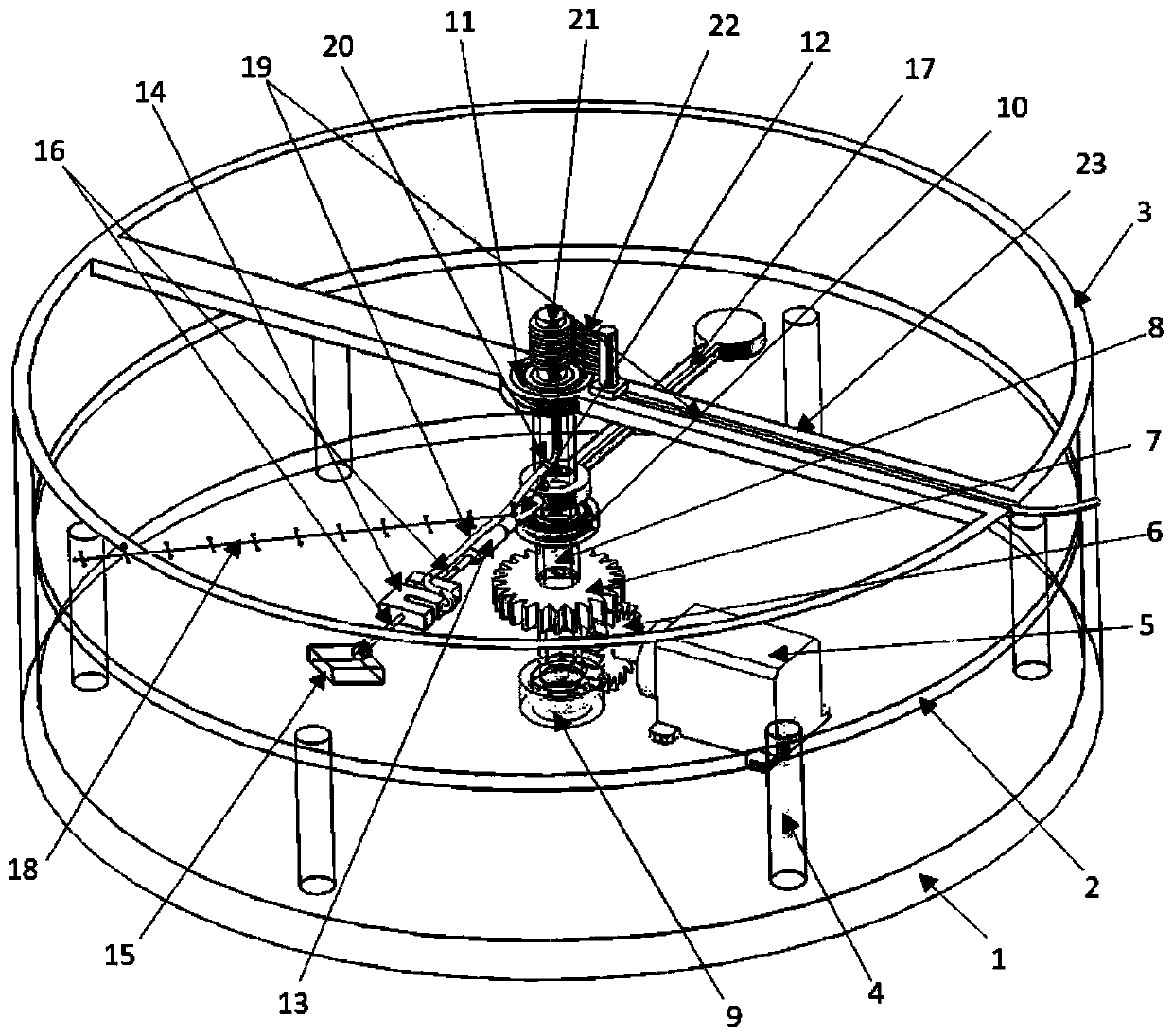

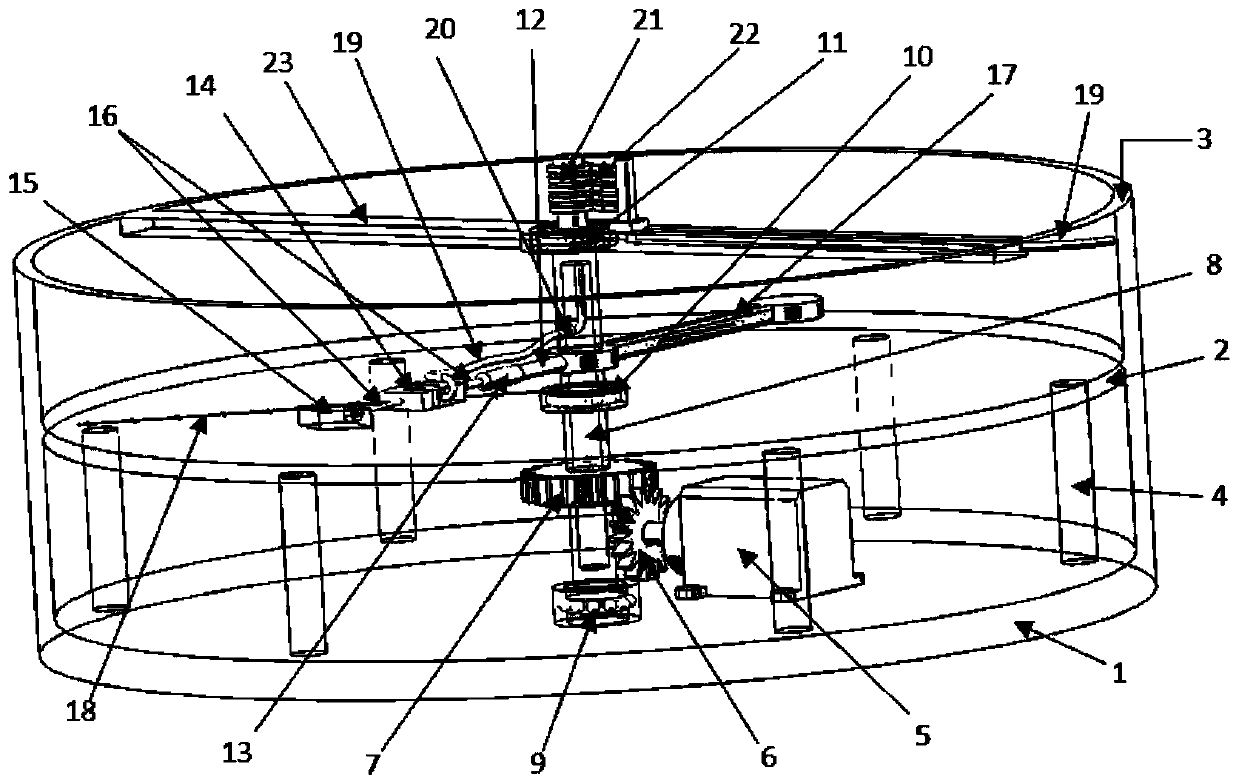

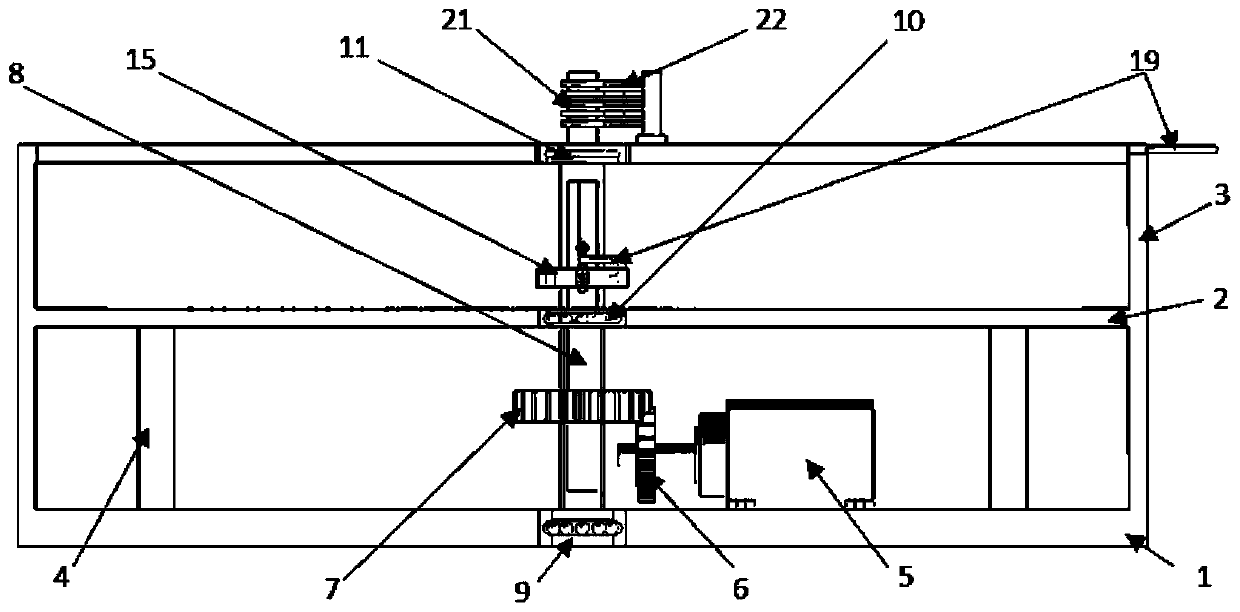

[0028] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] The present invention designs a static calibration device for tension sensors in a weightless environment, such as Figure 1-5 As shown, it includes chassis 1, dial 2, housing 3, support column 4, servo motor 5, gears 6 and 7, shaft 8, bearings 9, 10 and 11, fine-tuning arm 12, fine-tuning knob 13, tension sensor 14, standard Mass counterweight 15, string 16, balance beam 17, scale 18, sensor cable 19, small hole 20, slip ring 21, brush 22 and beam 23.

[0030] Chassis 1 needs to be fixed on the workbench. The rotating shaft 8 runs through the chassis 1 and the dial 2, and is connected with the chassis 1, the dial 2 and the beam 23 through bearings 9, 10, 11 respectively, and can rotate freely. The support column 4 supports and fixes the dial 2 . The casing 3 closes the periphery of the device. There is a scale 18 on the upper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com