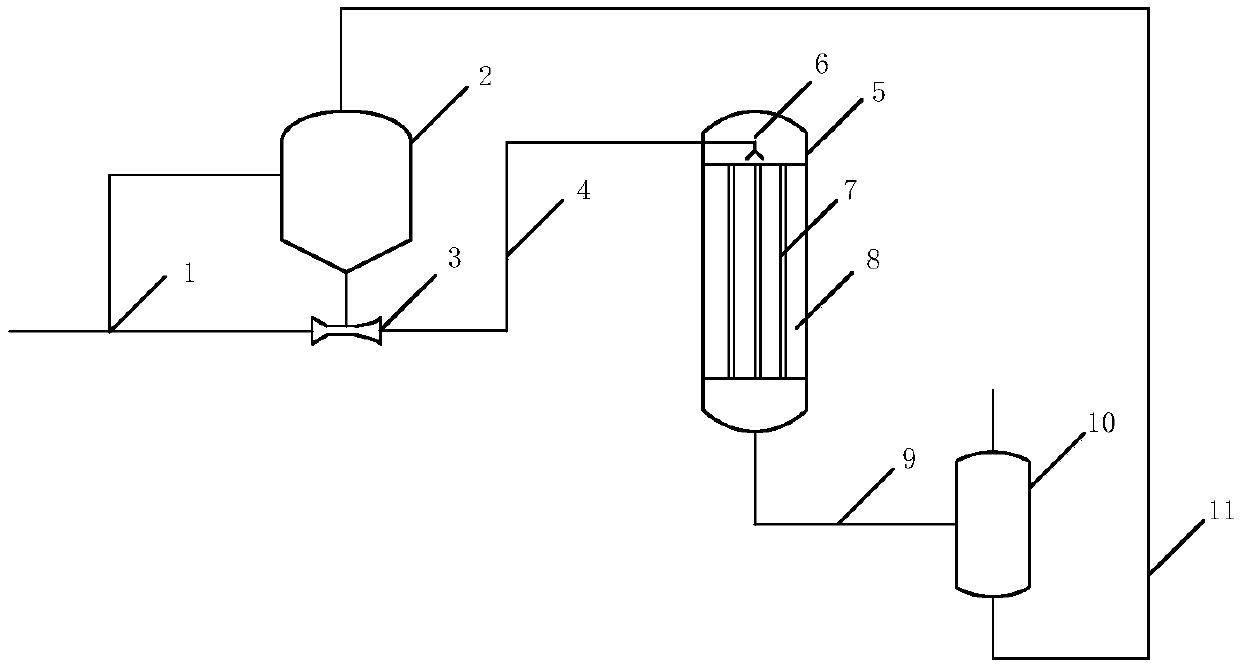

Opposed type solid particle spraying distributor online coke cleaning device

A solid particle, opposing technology, used in the cleaning of heat transfer devices, non-rotating equipment cleaning, lighting and heating equipment, etc., can solve problems such as deterioration of reaction system operating conditions, reduction of catalyst reaction performance, and increase of reactor operating pressure, etc. Achieve the effect of strengthening the gas-solid mixing effect, stabilizing the reaction performance, and maintaining the consumption level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

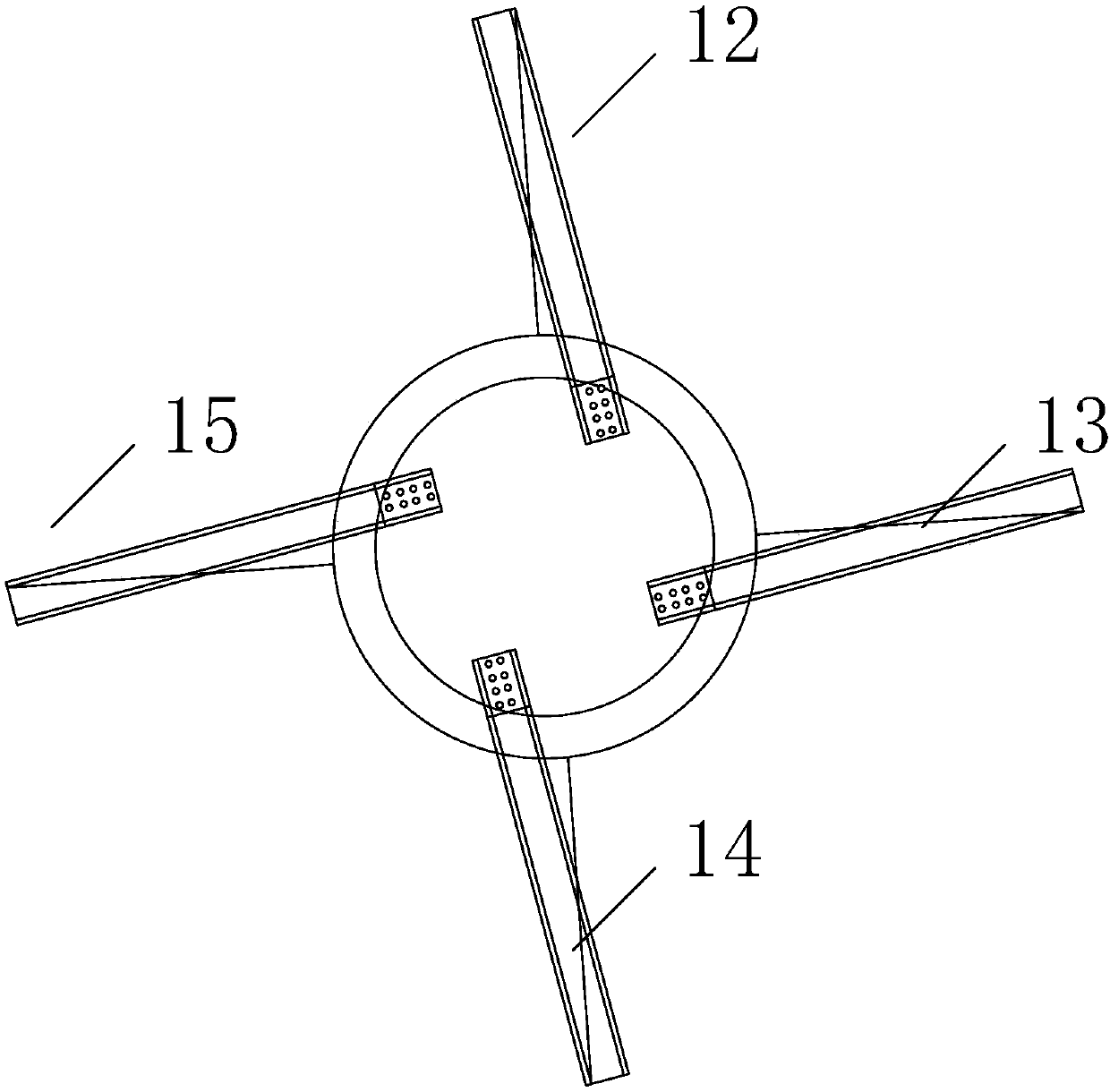

Embodiment 1

[0033] Adopt the on-line decoking device of solid particle recycling of the present invention, arrange jet distributor in the cooler upper head, jet distributor is made up of opposite type 4 nozzles, the pressure drop of reaction gas cooler at the initial stage of starting up is 4kPa, with inertness The gas nitrogen is used as the driving force, and the spherical iron ball particles with an average diameter of 5mm are transported to the opposed solid particle spray distributor through the solid particle feeder. After being sprayed by the distributor, the solid particles are distributed to the In each tube of the ammoxidation reaction gas cooler, the coke in the tubes was removed. When the acrylonitrile unit operated continuously for 24 months, the pressure drop of the cooler was 4.2kPa, which stabilized the resistance of the cooler tubes and pipes. The operating pressure of the reaction system and the acrylonitrile yield of the catalyst remain unchanged, which maintains the con...

Embodiment 2~9

[0034] Operate according to each condition and step of embodiment 1, just change the kind of inert gas, the average diameter of solid particles, the kind of solid particles, the shape of solid particles, the ejection speed of solid particles, the type of distributor, the number of placements, The type and number of gas-solid separators, the ratio of the opening diameter of the protective plate to the inner diameter of the tube, etc., the specific process operating conditions and the pressure drop of the reaction gas cooler after the operation of the device, the change of the acrylonitrile single-recovery of the catalyst, and the operation of the device See Table 1 and Table 2 for the results of cycle, cooler tube sheet and tube erosion and wear.

[0035] Table 1 comparative example and embodiment process condition contrast

[0036]

[0037]

[0038] Table 2 comparative example and embodiment device operation result contrast

[0039]

[0040] Note: The sign "-" in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com