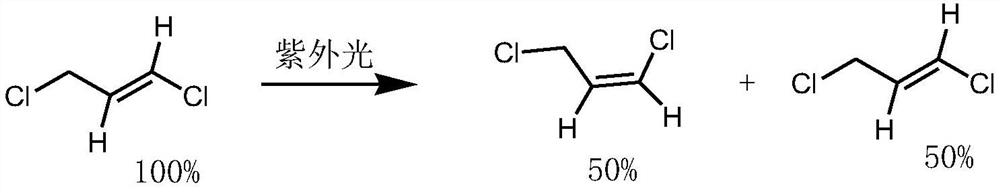

Trans-1,3-dichloropropene in situ inversion method to obtain cis-1,3-dichloropropene

A technology of dichloropropene and dichloroethylene, which is applied in the fields of organic chemistry methods, chemical instruments and methods, halogenated hydrocarbon preparation, etc., can solve the problems such as inability to synthesize propargyl alcohol, and achieves increased raw material utilization rate, reduced emission and efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) 250ml quartz-jacketed glass reaction kettle, adding concentration is 5wt% (percentage by weight concentration, the following examples are the same) methanol solution 100ml of trans-1,3-dichloroethene, add 0.1% photoaccelerator Anthracene N2 slightly bubbling;

[0024] (2) Add 0.1% photoaccelerator anthracene;

[0025] (3) Then start light irradiation: 40w, 310nm LED light irradiation, temperature control at 25 degrees, gas phase detection of cis-trans isomerization ratio. After 1.2 hours of light, the cis-trans isomerization ratio was 1:2, the reaction was stopped, and the reaction product was obtained.

Embodiment 2

[0027] (1) 250ml quartz-jacketed glass reaction kettle, add 100ml of methanol solution of 5% trans-1,3-dichloroethylene, N2 slightly bubbling;

[0028] (2) Add 0.1% photoaccelerator anthracene;

[0029] (3) Then start light irradiation: 40w, 310nm LED light irradiation, temperature control at 25 degrees, gas phase detection of cis-trans isomerization ratio. After 0.5h of light, the cis-trans isomerization ratio was 1:2, the reaction was stopped, and the reaction product was obtained.

Embodiment 3

[0031] (1) 250ml quartz-jacketed glass reactor, add 100ml of methanol solution of 5% trans-1,3-dichloroethene, N2 slight bubbling;

[0032] (2) Add 0.1% photoaccelerator anthracene;

[0033] (3) Then start light irradiation: 40w310nm LED light irradiation, temperature control at 50 degrees, gas phase detection of cis-trans isomerization ratio. After 1.2 hours of light irradiation, the cis-trans isomerization ratio was 1:1.5, the reaction was stopped, and the reaction product was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com