A wire device for textile machine yarn

A technology of mechanical yarn and wire, which is applied in textiles and papermaking, transportation and packaging, and thin material processing, etc. It can solve problems affecting the normal operation of textile machinery, increasing costs, and yarn breakage, and achieves simplified installation and disassembly steps and simplified Installation steps, the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

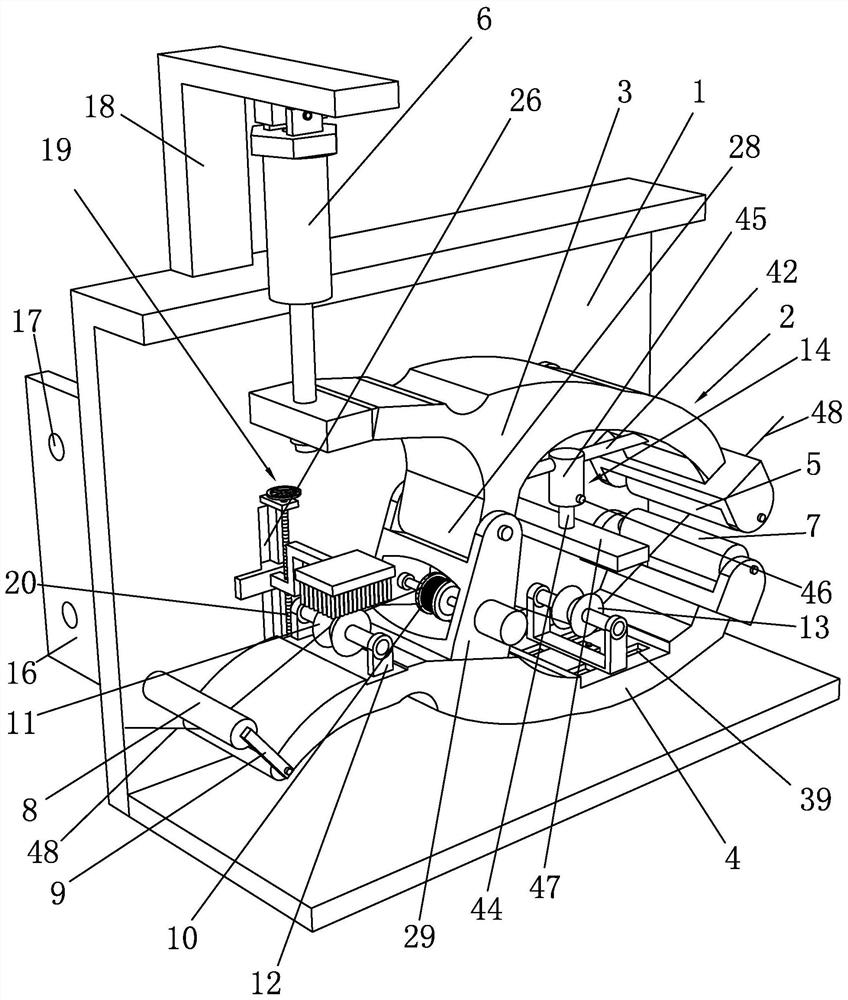

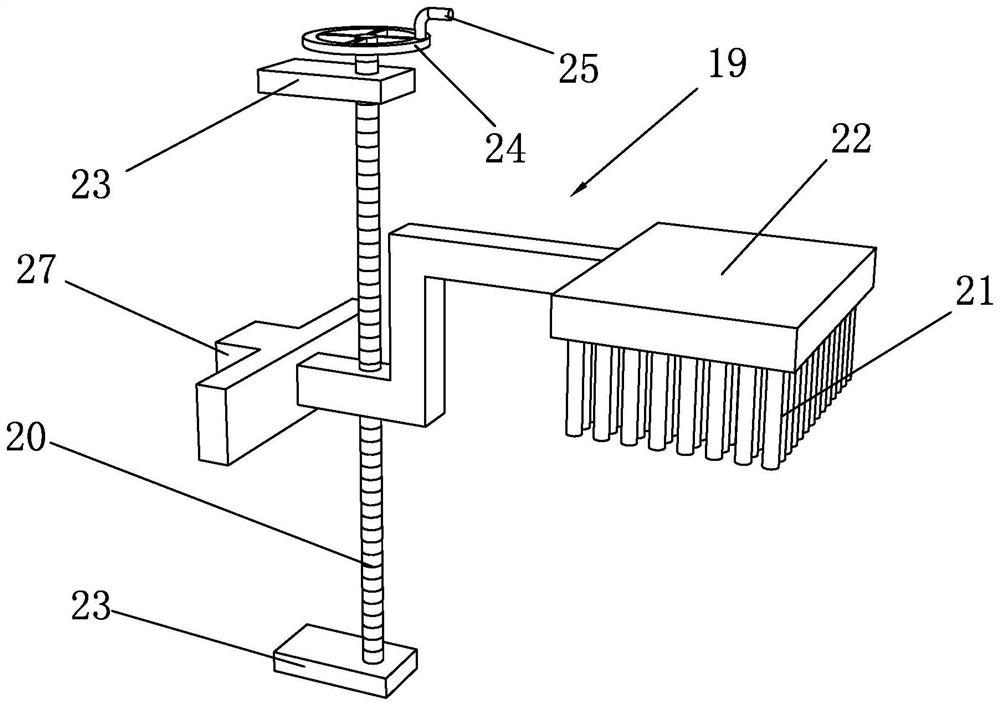

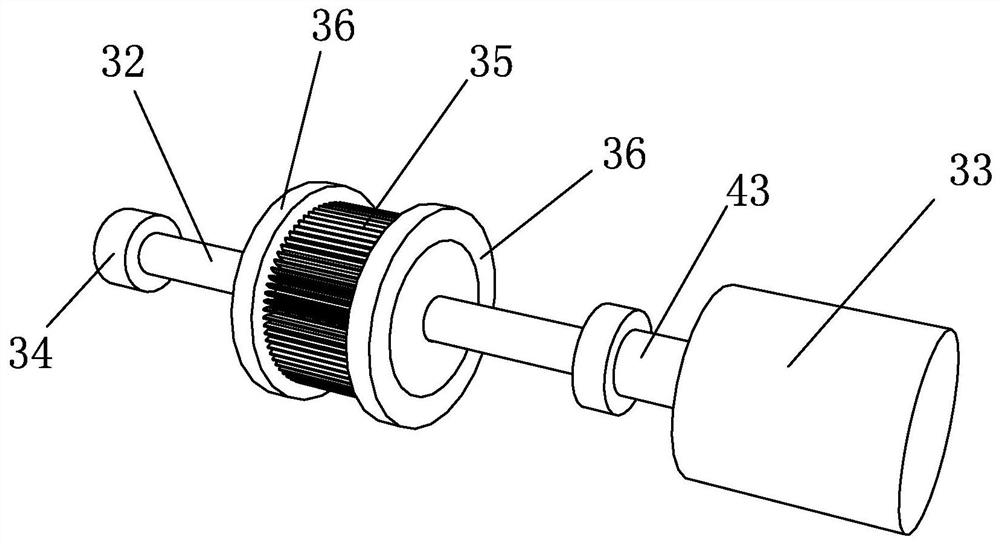

[0023] Such as Figure 1 to Figure 5 As shown, it is a wire device for textile machine yarn according to the present invention, which includes a fixed frame 1 and a wire frame 2, and extension blocks 16 are arranged on the left and right ends of the rear side of the fixed frame 1, and the extension blocks 16 are provided with fixed Holes 17, the top surface of the fixed frame 1 is provided with a folded plate 18, the top of the adjustment cylinder 6 is hinged and fixed with the folded plate 18, the design of the extension block 16 is convenient for installation and fixing between the fixed frame 1 and the textile machine, the fixed hole The design of 17 can further simplify the installation steps and facilitate the actual disassembly and assembly. The design of the folding plate 18 can facilitate the installation and fixing between the adjustment cylinder 6 and the fixed frame 1. The top of the adjustment cylinder 6 and the folding plate 18 are designed to be hinged. The conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com