Method for pultrusion of cabinet door panel using pultrusion die

A die head and door panel technology, which is applied in the field of pultrusion of cabinet door panels using pultrusion die heads, can solve the problems of high labor intensity, low bonding strength, easy detachment, etc., so as to reduce labor intensity, improve bonding strength, and be difficult to detach. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

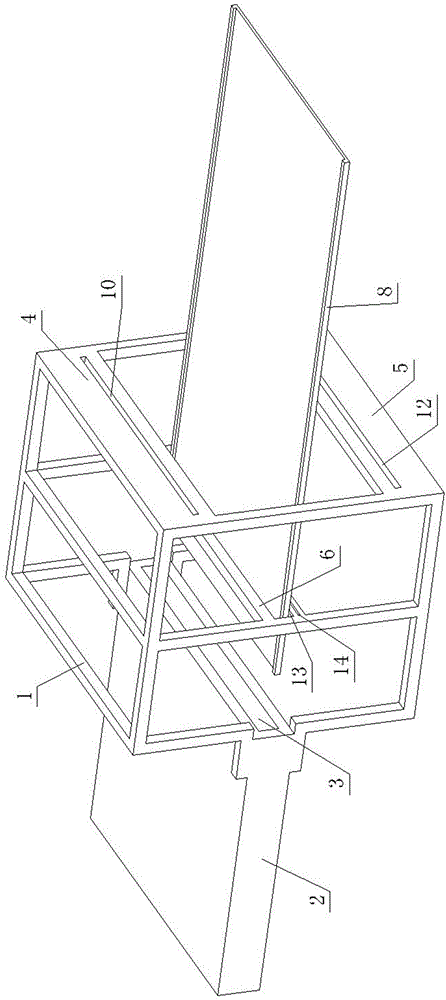

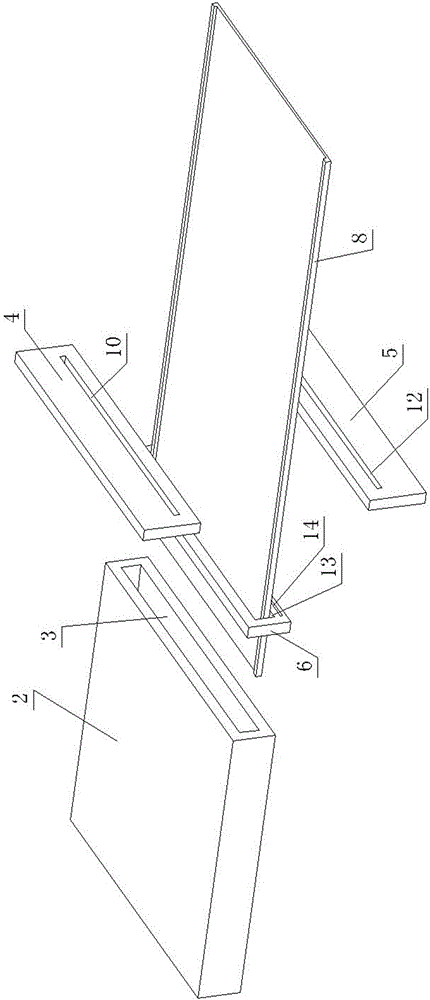

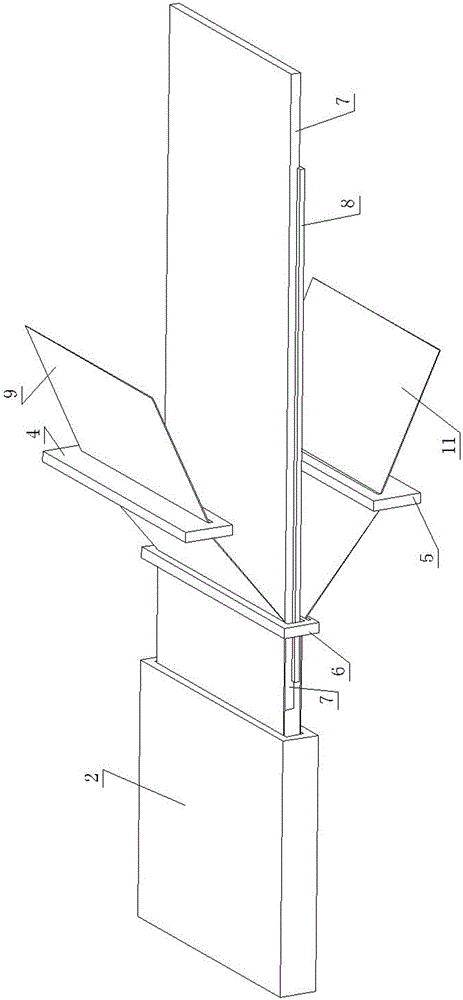

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the pultrusion die head of the present invention includes a support 1 and a die head body 2 for heating and shaping the fiberglass raw material cloth with a heating device such as a heating wire. The die body 2 runs through a pultrusion channel 3 whose cross section matches the shape and size of the door panel section, that is, the pultrusion channel 3 has the same shape and size as the door panel section. The die head body 2 is fixed on the support 1, and the support 1 is also fixed with an upper feed plate 4, a lower feed plate 5, a gathering plate 6 and a feed rail 8 for shelving the foam filling plate 7. The upper feed plate 4 is positioned above the feed track 8, and the lower feed plate 5 is located below the feed track 8. The upper feed plate 4 is provided with an u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com