Novel fireproof flame retardant plate

A new type of fire-resistant and flame-retardant technology, which is applied in wood treatment, coating impregnation, wood processing equipment, etc., can solve the problems of general fire-proof performance of fire-resistant wood and cannot meet the fire-proof effect of people, and achieve the effect of avoiding fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

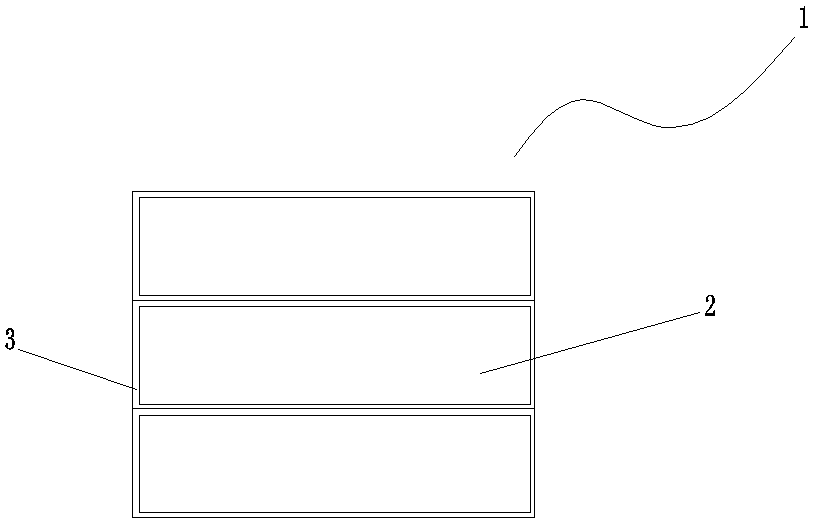

[0012] A new type of fireproof flame retardant board described in this embodiment 1, such as figure 1 As shown, the fire-proof and flame-retardant board 1 is formed by pressing several boards 2, and the surfaces of the several boards are provided with a fire-proof and flame-retardant layer 3, and the fire-proof and flame-retardant layer is applied to the The fire retardant on the surface of several boards is solidified, and the weight percentage of the fire retardant is composed of 72% water, 8% ammonium polyphosphate, 8% ammonium chloride, 4% dispersant, and 5% catalyst , Coagulant 3%.

[0013] Further, the catalyst is silicic acid.

[0014] Further, the coagulant is propylene glycol or disodium edetate or disodium stannous citrate.

[0015] The surface of each layer of the fire-resistant and flame-retardant board is coated with a fire-resistant and flame-retardant layer, so that the fire-resistant and flame-retardant board also has a fire-resistant and flame-retardant effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com