Rolling cutter for ultrasonic high-speed rotary blowing discharging

A high-speed rotating, ultrasonic technology, applied in the cutting of textile materials, textile and papermaking, metal processing, etc., can solve the problems of complicated machine debugging, unsatisfactory cutting effect, and reduced machine efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

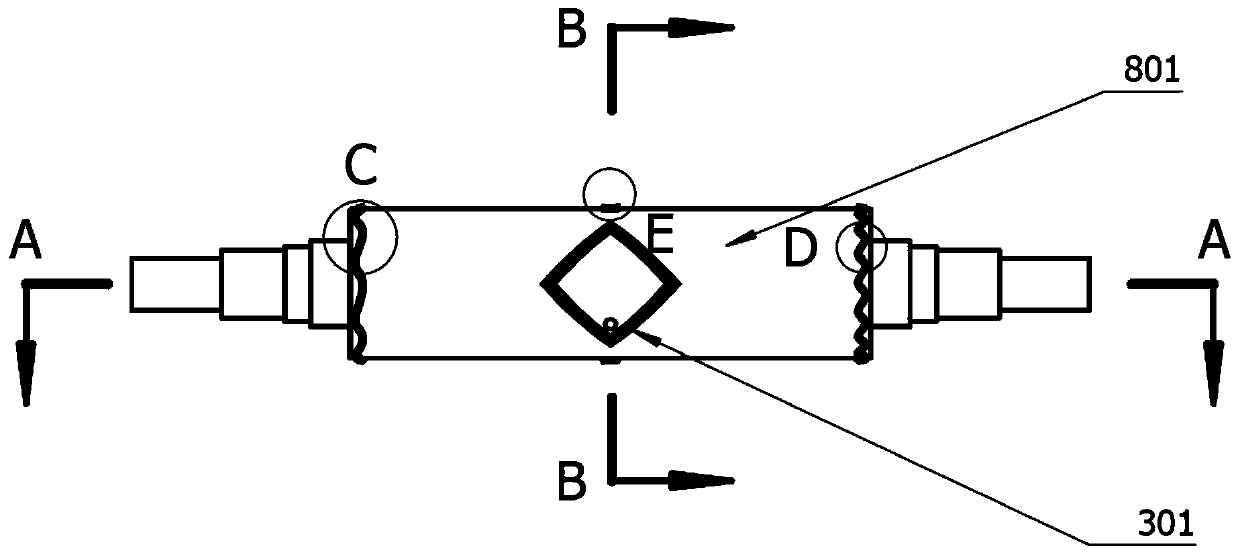

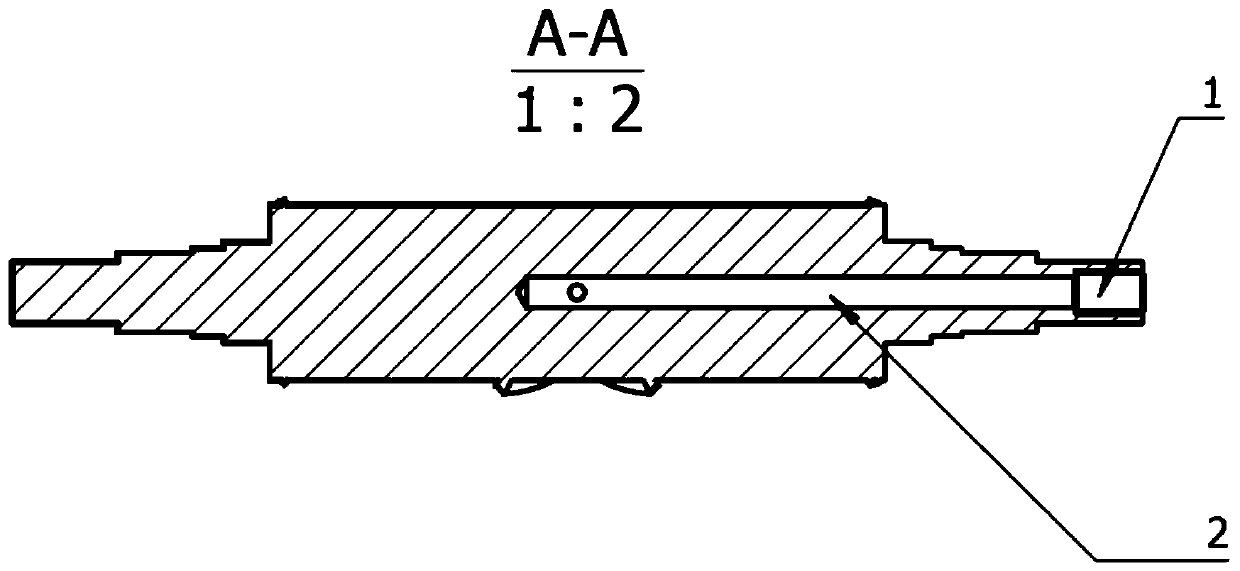

[0030] The roller knife used for ultrasonic high-speed rotary blowing and discharging is provided with a roller knife 8, the shaft end surface on the right side of the roller knife 8 has a central deep slot hole 2, and the shaft end surface of the central deep slot hole 2 has a section of threaded hole 1, the threaded hole 1 Connect the roller knife 8 and the high-speed rotary joint 7;

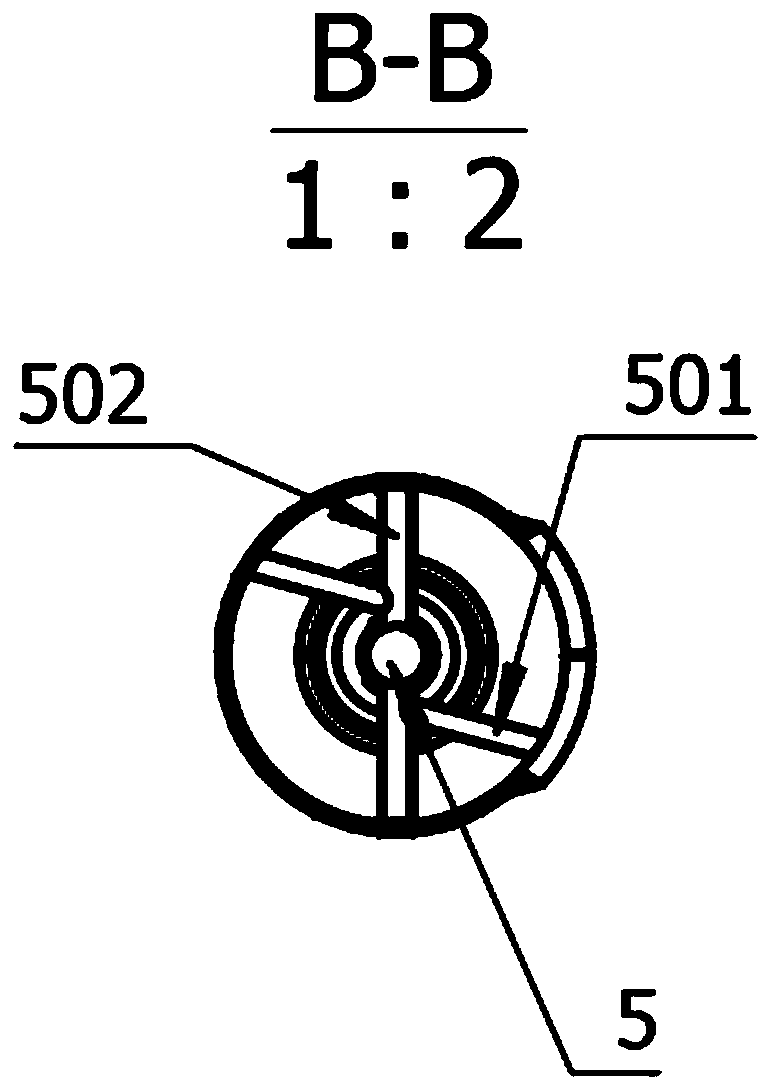

[0031] Roller knife 8 has comprised threaded hole 1, center deep long hole 2, cutting blade 301, punching cutting blade 302, left side protection blade 4, tangential hole 501, normal hole 502, right side protection blade 6, cutter body 801. Cutting blade 301, punching cutting blade 302, left side protective edge 4, right side protective edge 6, are positioned at cutter body 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com