Tar leakage preventing structure and method for electronic cigarette

A technology for preventing oil leakage and electronic cigarettes, which is applied in the fields of tobacco, smokers’ products, applications, etc., and can solve problems such as circuit short circuit, adverse effects on brand quality, and failures, so as to improve product qualification rate, reduce oil leakage risk, and improve mechanical structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following specific description, many specific details are set forth in order to fully understand the present invention, but the present invention can also be implemented in other ways different from this description, therefore, the protection scope of the present invention is not limited by the specific implementation disclosed below. Example limitations.

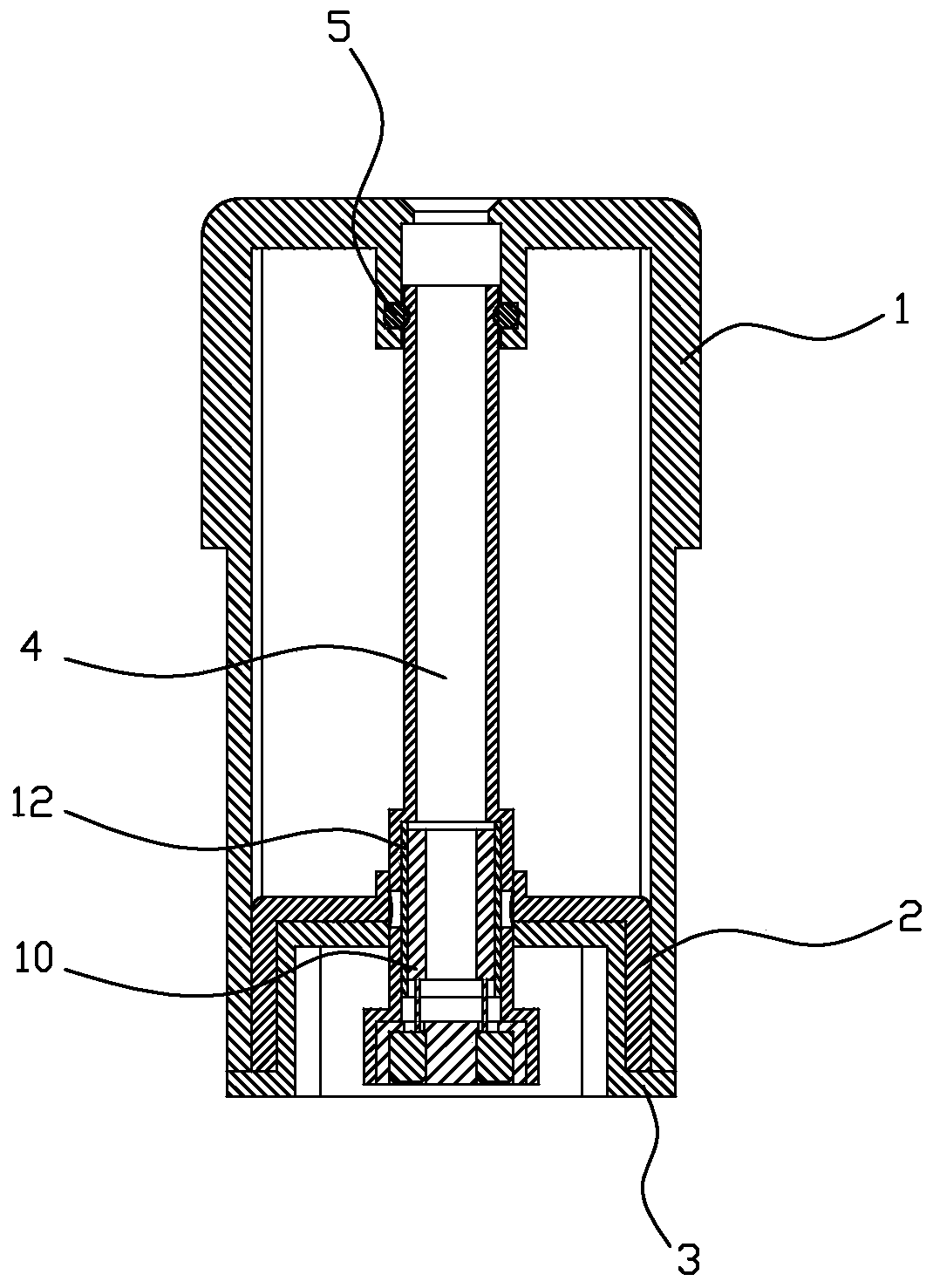

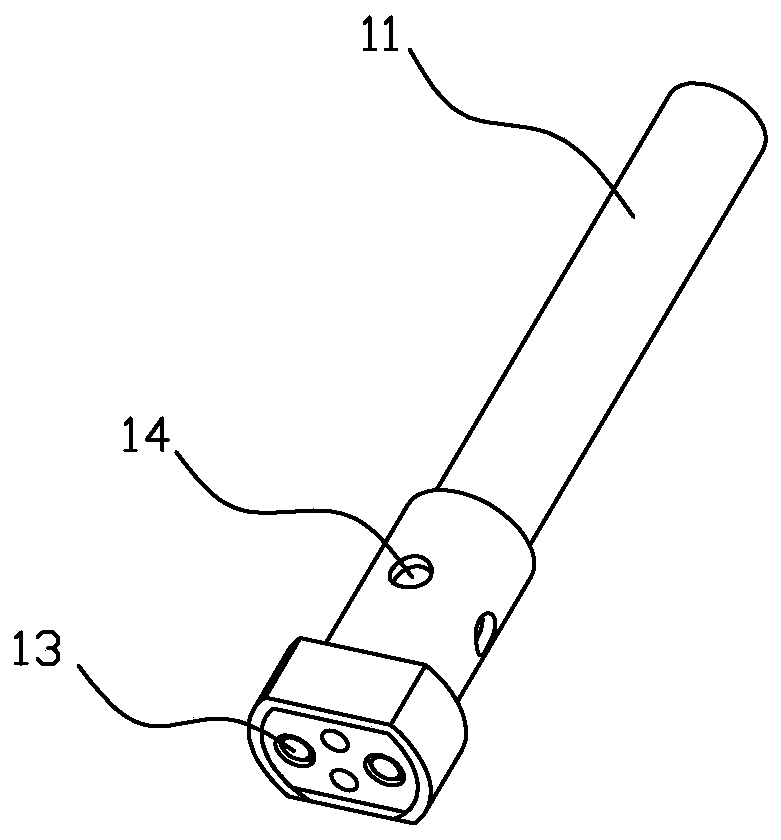

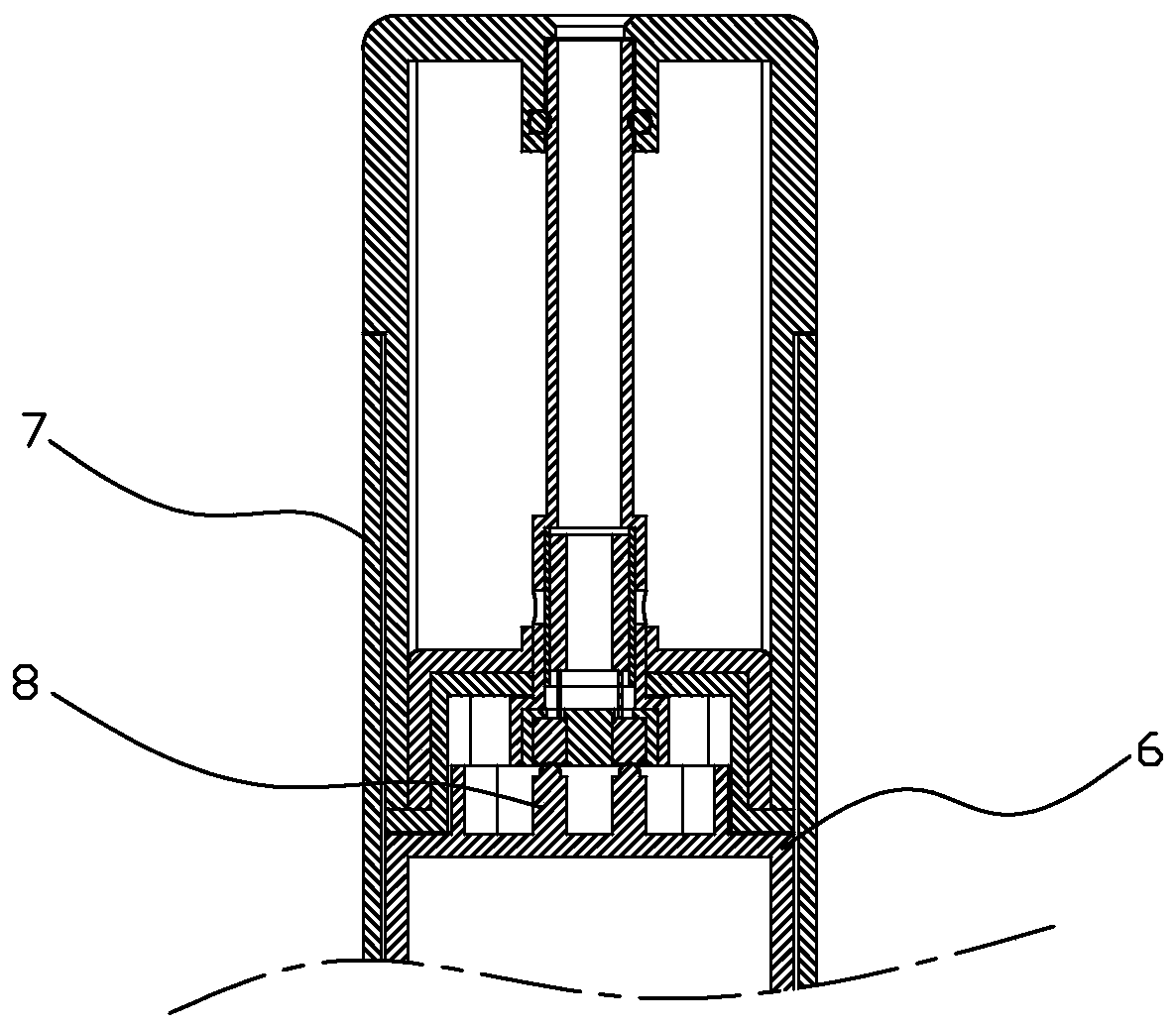

[0037] Such as Figure 1-4 Shown, in specific embodiment 1,

[0038] An electronic cigarette oil leakage prevention structure of the present invention includes:

[0039] A cartridge, including: atomization component 4, oil tank 1, sealing silica gel 2 and base 3; atomization component 4 is set at the central axis position, oil tank 1 is set on the outer ring of atomization component 4, and sealing silicone 2 is set on the In the middle of the oil tank 1, the base 3 is arranged outside the sealed silica gel 2; the oil tank 1 is a cavity-like structure.

[0040] A battery rod, the battery rod includes: a batt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com