FAKRA connector and manufacturing method thereof

A connector and integrated technology, which is applied in the direction of connection, contact manufacturing, and two-component connection devices, etc., can solve problems such as inability to guarantee product life, coaxiality, terminal module skew, etc., to ensure service life and prevent The effect of inserting crookedly and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

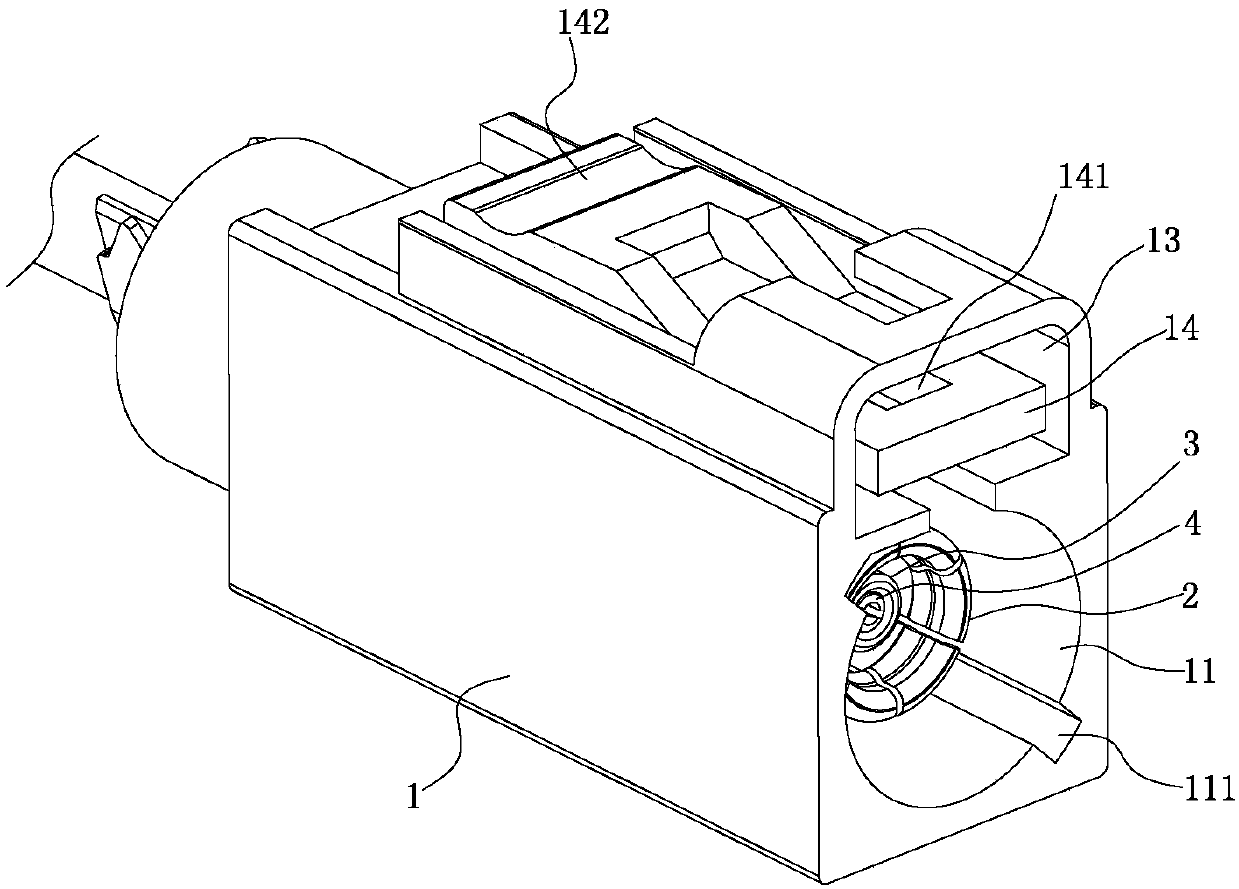

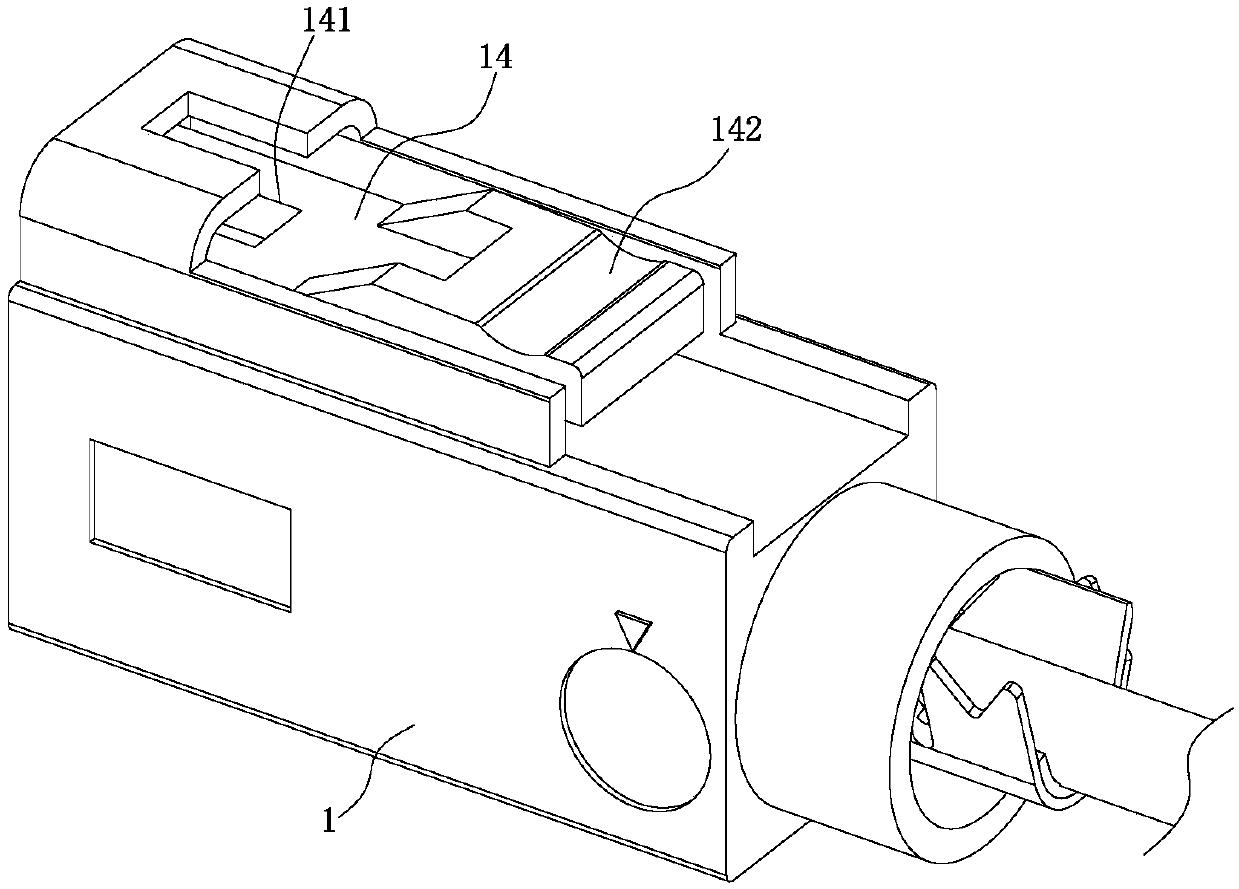

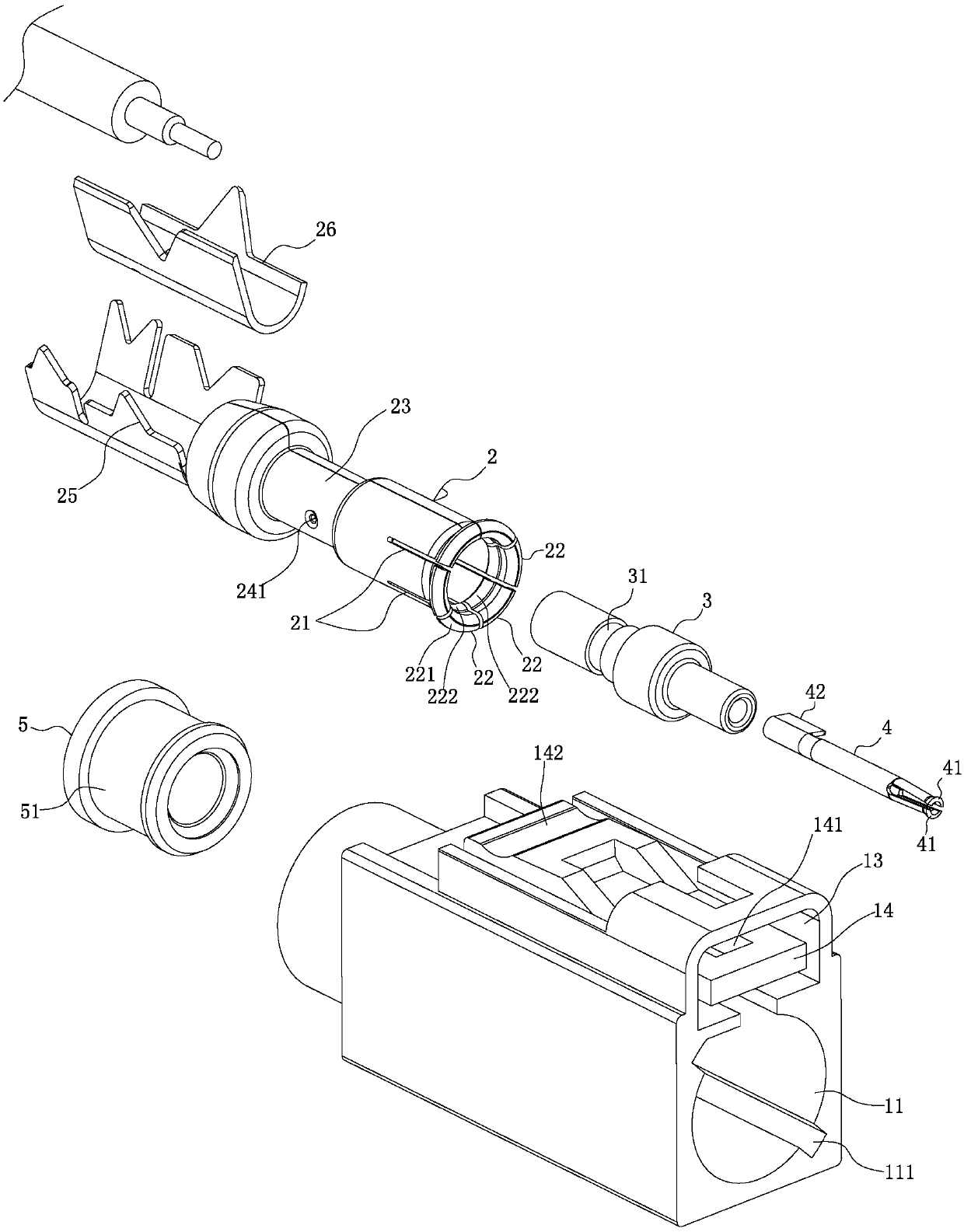

[0030] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0031] See Figure 1-7 As shown, it is a FAKRA connector, which includes: a plastic seat 1, a metal shell 2 inserted in the plastic seat 1, an insulating seat 3 set in the metal shell 2, and a metal shell set in the insulating seat 3 The terminal 4, the metal shell 2, the insulating seat 3 and the metal terminal 4 are coaxially arranged, and the front ends of the metal shell 2, the insulating seat 3 and the metal terminal 4 are all exposed in the butt hole 11 of the plastic seat 1; the metal shell An annular insertion groove is formed between the inner wall 2 and the outer wall of the insulating seat 3, and the front end of the metal terminal 4 protrudes to the front end surface of the insulating seat 3.

[0032] An elastic buckle 12 is formed inside the plastic seat 1, and the elastic buckle 12 includes a base 121 integrally formed inside the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com