High energy density fast charging type lithium ion power battery

A high energy density, power battery technology, applied in batteries, secondary batteries, battery electrodes, etc., can solve the problems of inability to meet the requirements of battery life, low energy density, and insignificant improvement in energy density, and achieves increased lithium intercalation. The effect of reaction area, high energy density, and rapid diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Preparation of Li-ion power battery.

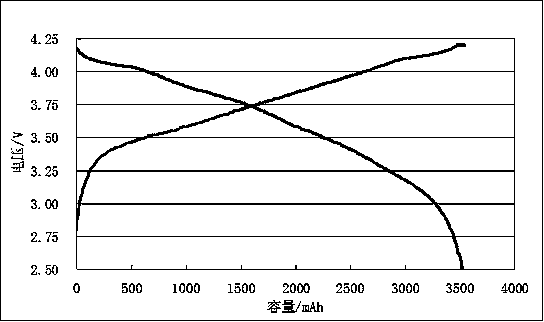

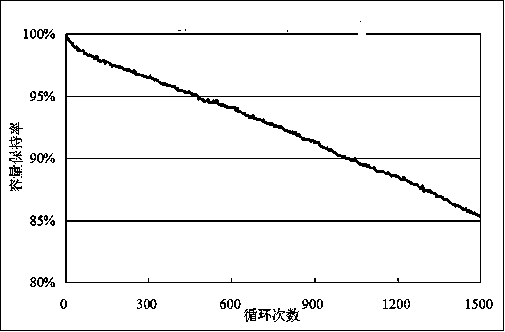

[0041] In this embodiment, a cylindrical 18650-3500mAh lithium-ion power battery is prepared, including a positive pole piece, a negative pole piece, a diaphragm, an electrolyte and battery auxiliary materials, wherein the positive pole piece, the diaphragm and the negative pole piece are wound together into a roll core, The winding core is placed inside the casing, and the roller groove is tested for internal short circuit, baked at 80°C for 24 hours, injected with electrolyte, sealed, then cleaned the casing, and coated with thermoplastic film. The cell is aged for 12 hours to obtain the finished cell. Then make the finished battery.

[0042] In this embodiment, the positive electrode sheet includes a positive electrode material layer, and the formula of the positive electrode sheet is composed of the following components: LiNi 0.92 co 0.05 al 0.03 o 2 (0.2C gram capacity 200mAh / g) ternary material (conductive carbon laye...

Embodiment 2

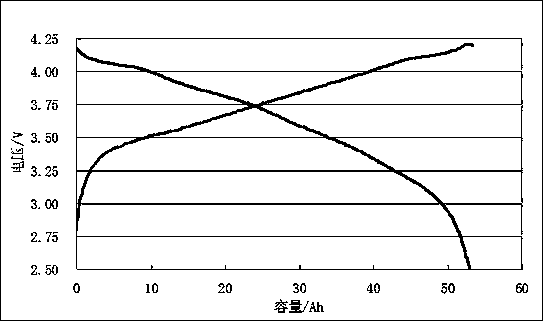

[0053] 1. Preparation of Li-ion power battery.

[0054] In this example, a square 2614891-52Ah lithium-ion power battery is prepared, including a positive electrode sheet, a negative electrode sheet, a separator, an electrolyte, and battery auxiliary materials, wherein the positive electrode sheet, the separator, and the negative electrode sheet are wound together into a core, and the core is multiple Tab design, the winding core is placed inside the shell, the internal short circuit is tested, baked at 80°C for 24 hours, the electrolyte is injected, the opening is formed, the seal is laser welded, and then the shell is cleaned. The cells are aged for 12 hours to obtain finished cells, and then made into finished batteries.

[0055] In this embodiment, the positive electrode sheet includes a positive electrode material layer, and the formula of the positive electrode sheet is composed of the following components: LiNi 0.80 co 0.15 al 0.05 o 2 (0.2C gram capacity 180mAh / g) ...

Embodiment 3

[0066]1. Preparation of Li-ion power battery.

[0067] In this example, a soft pack 2014891-40Ah lithium-ion power battery is prepared, including a positive electrode sheet, a negative electrode sheet, a diaphragm, an electrolyte, an aluminum-plastic film, and battery auxiliary materials, wherein the positive electrode sheet, the diaphragm, and the negative electrode sheet are wound together into a roll core , the winding core is placed inside the aluminum-plastic film, the internal short circuit is tested, baked at 80°C for 24 hours, injected with electrolyte, and sealed twice. The cell is aged for 12 hours to obtain the finished cell.

[0068] In this embodiment, the positive electrode sheet includes a positive electrode material layer, and the formula of the positive electrode sheet is composed of the following components: LiNi 0.80 co 0.15 Al 0.05 o 2 (0.2C gram capacity 180mAh / g) ternary material (conductive carbon layer coating modification), the dosage is 97.5wt%; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com