Method for generating Bezier-like light beam through optical fiber end face growth microcone

A Bessel beam and fiber end face technology, applied in optics, optical components, instruments, etc., can solve the problems of low height, surface roughness, time-consuming chemical process, etc., and achieve high quality, wide working wavelength range, and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to express the purpose and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings.

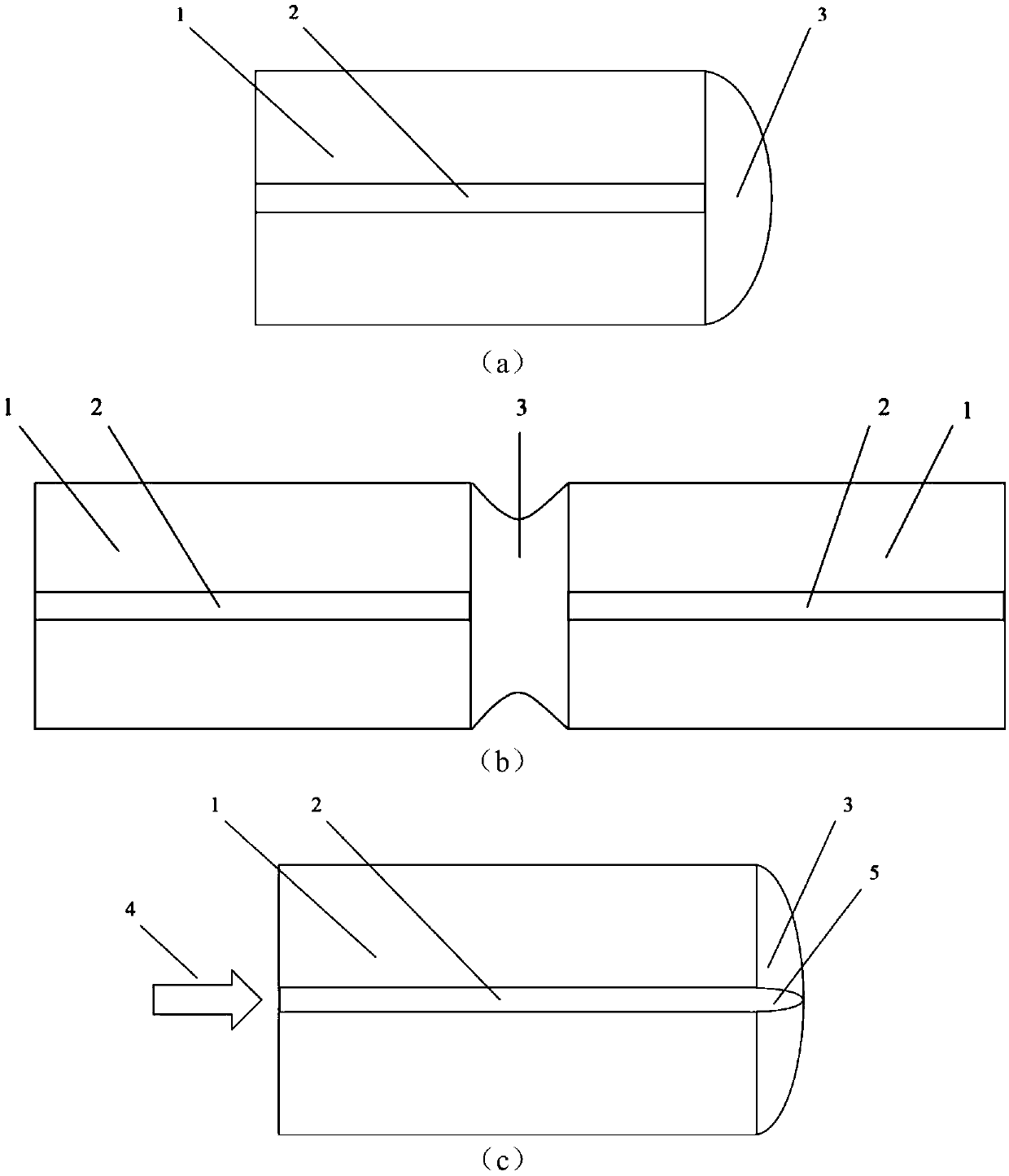

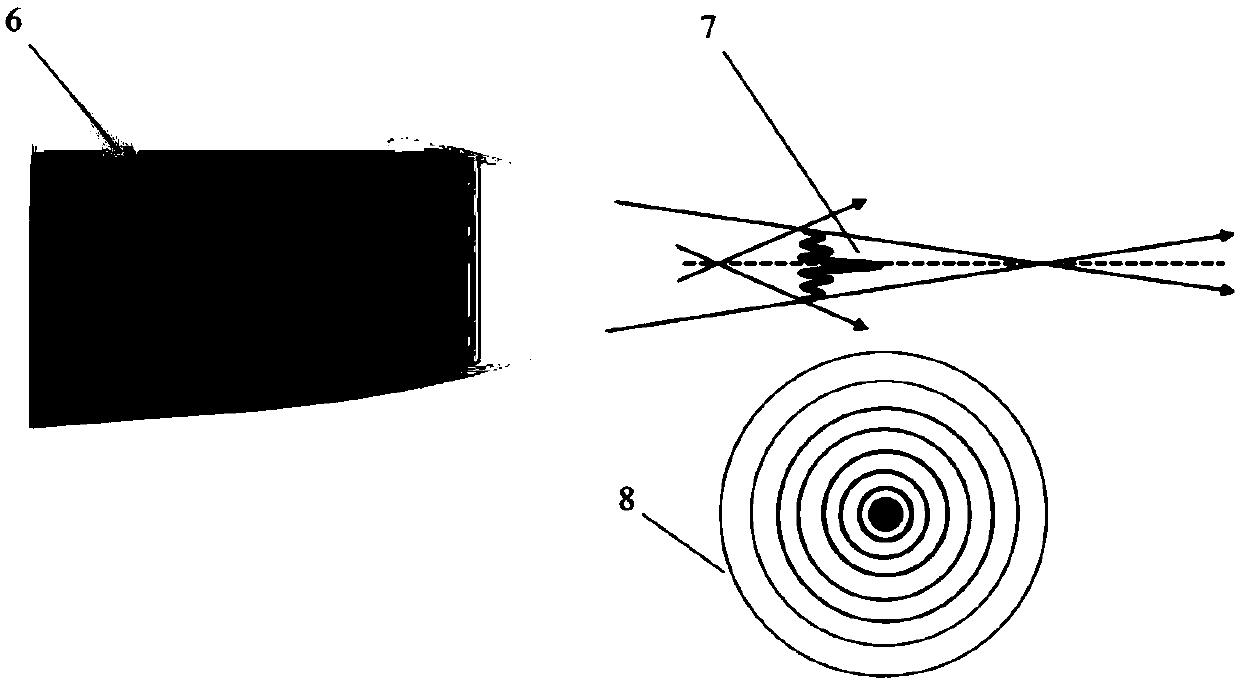

[0024] The technology for generating Bessel-like beams by polymer microcones proposed in the present invention is specifically to directly generate high-efficiency Bessel-like beams by growing photopolymer microcones on the end faces of optical fibers. A green laser is used to selectively solidify the liquid formulation on the fiber end face to form photopolymer microcones, and the length and shape of the microcones are precisely optimized for efficient Bessel-like beam generation. The length of the microcone is controlled by the choice of droplet height, and the shape of the microcone is controlled by photopolymerization parameters such as green laser power, laser exposure time and oxygen diffusion concentration. The working bandwidth of this microcone covers the entire vis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com