Testing device for testing shield cutter head-soil body intermediate lateral adhesion force

A technology of shield cutter head and test device, applied in the field of tunnel engineering, can solve the problems of lack of test equipment, unreasonable structure, lack of basis for value selection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

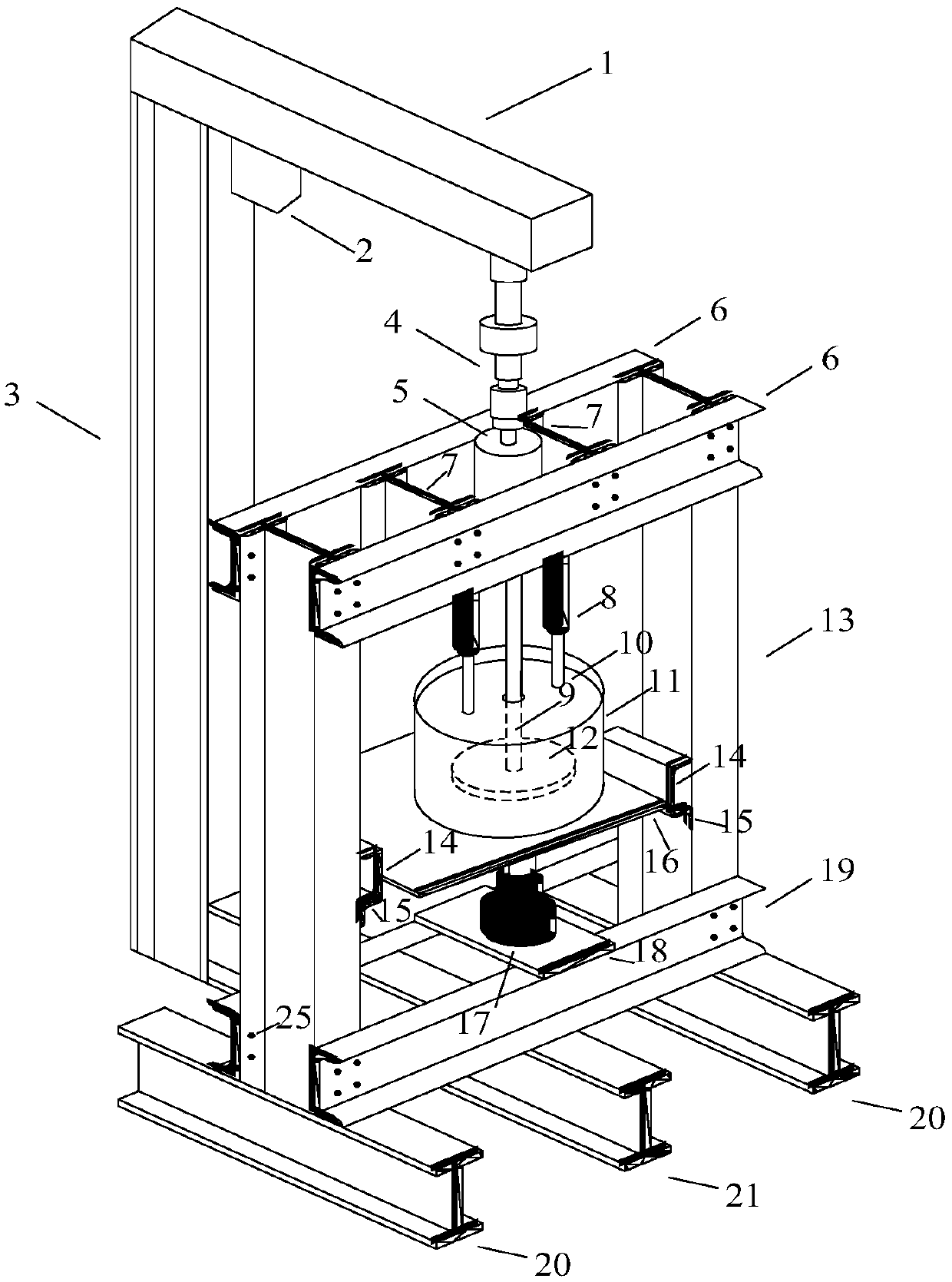

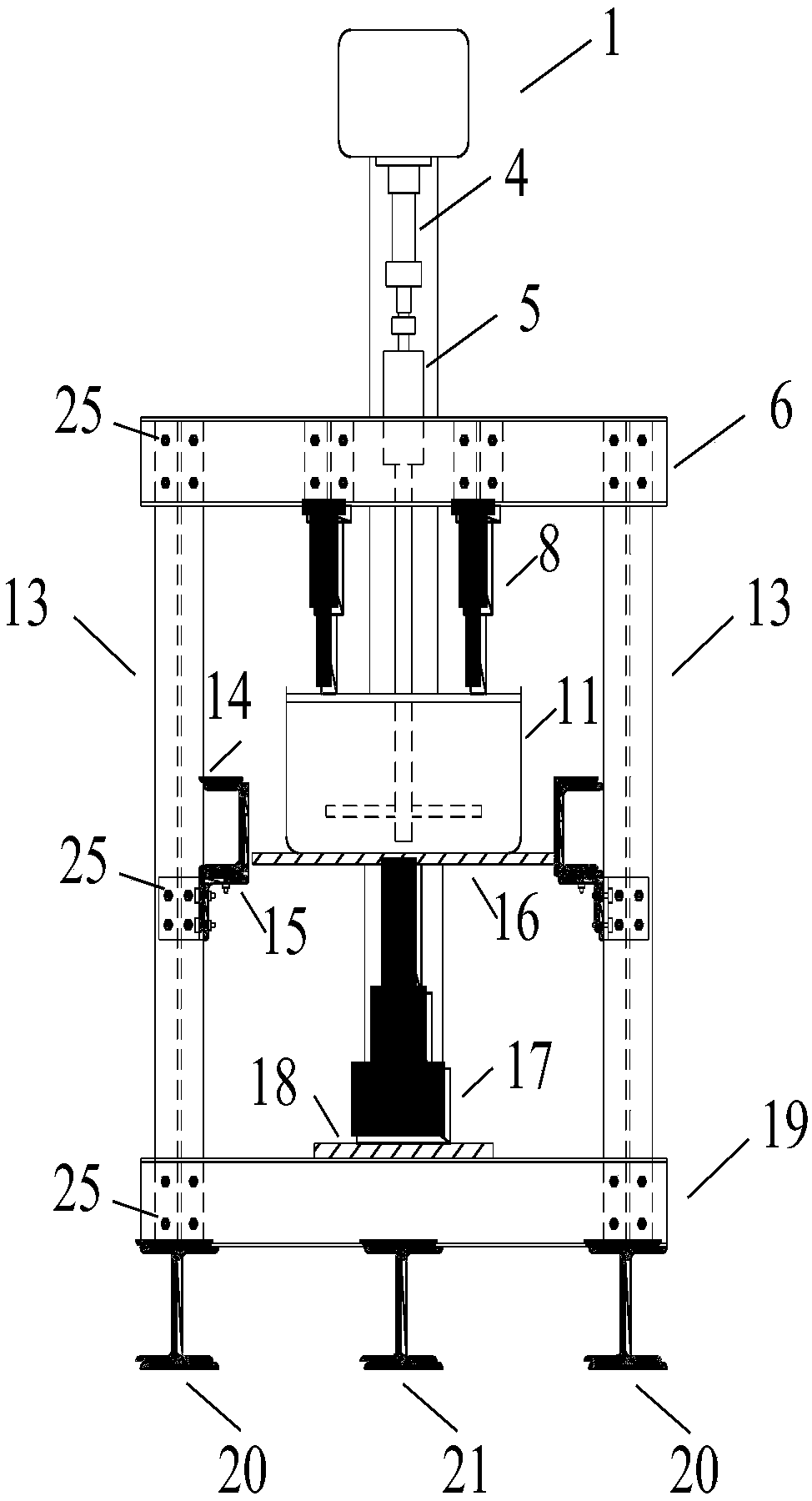

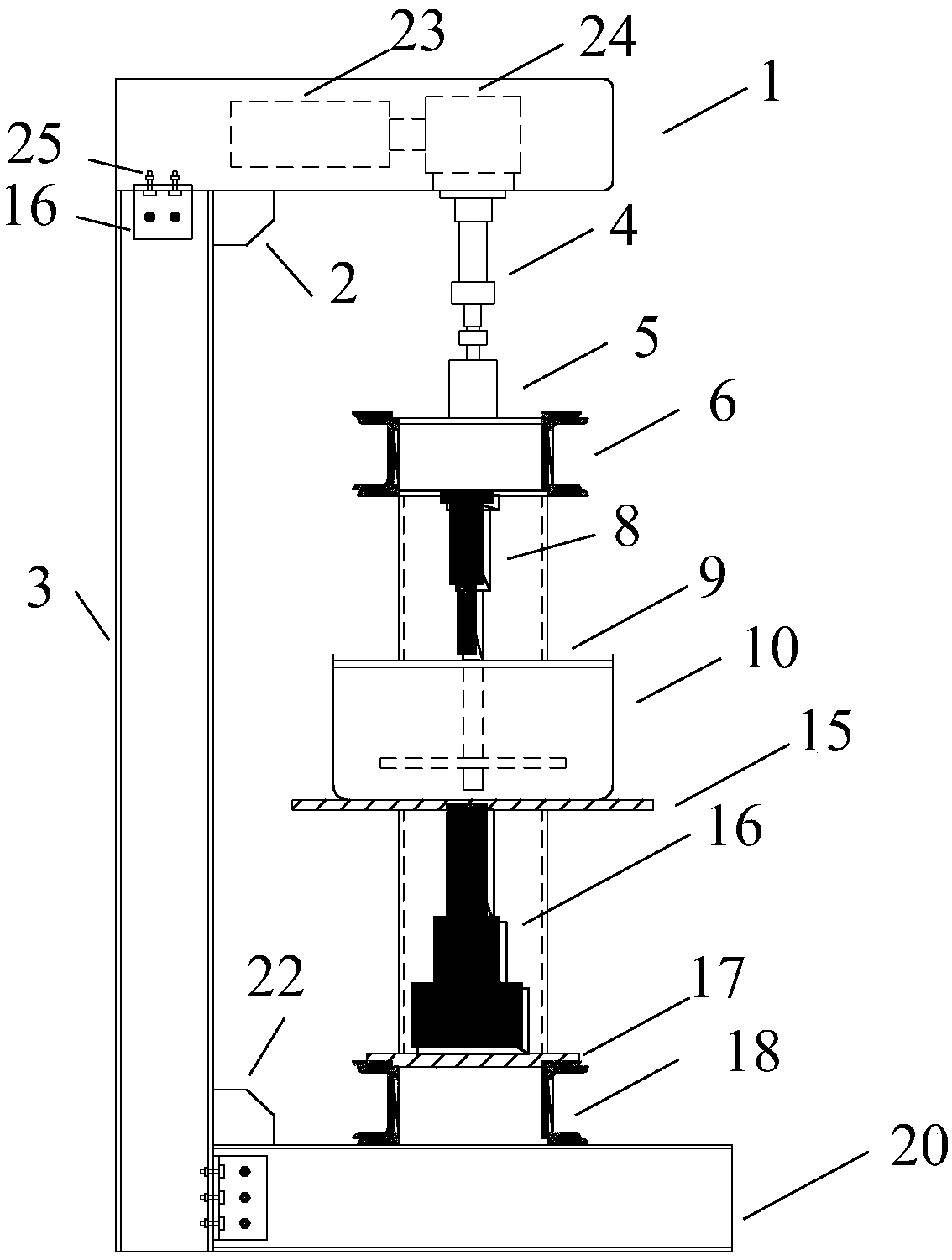

[0023] A test device for testing the dynamic lateral adhesion between shield cutterhead and soil, as attached figure 1 , 2 , Shown in 3, 4, the composition of this device is:

[0024] (1) Power rotation system: the rotating loading arm 1 and the base beam 21 are installed horizontally at both ends of the vertical load arm 3 respectively, and the rotating loading arm 1 and the base beam 21 are connected by angle steel 15, bolts 25 stiffening plate 2, stiffening plate The plate 22 is connected with the vertical bearing arm 3; a power mechanism 24, a reduction motor 23 and a shaft coupling 4 are installed on the rotating loading arm 1, and the shaft coupling 4 is connected with the vertical rotating shaft 9, and the rotating shaft 9 is driven by the rotating loading arm 1. The power mechanism 24 of the arm 1 is driven, and the rotation speed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com