Ash clearing device for boiler flue

A technology for cleaning ash device and boiler flue, which is used in the removal of solid residues, combustion products treatment, combustion methods, etc., and can solve the problems of inability to remove oil stains, incomplete cleaning process of flue, and strong adhesion of oil stains. , to achieve the effect of convenient and fast removal process, thorough cleaning process and improved cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

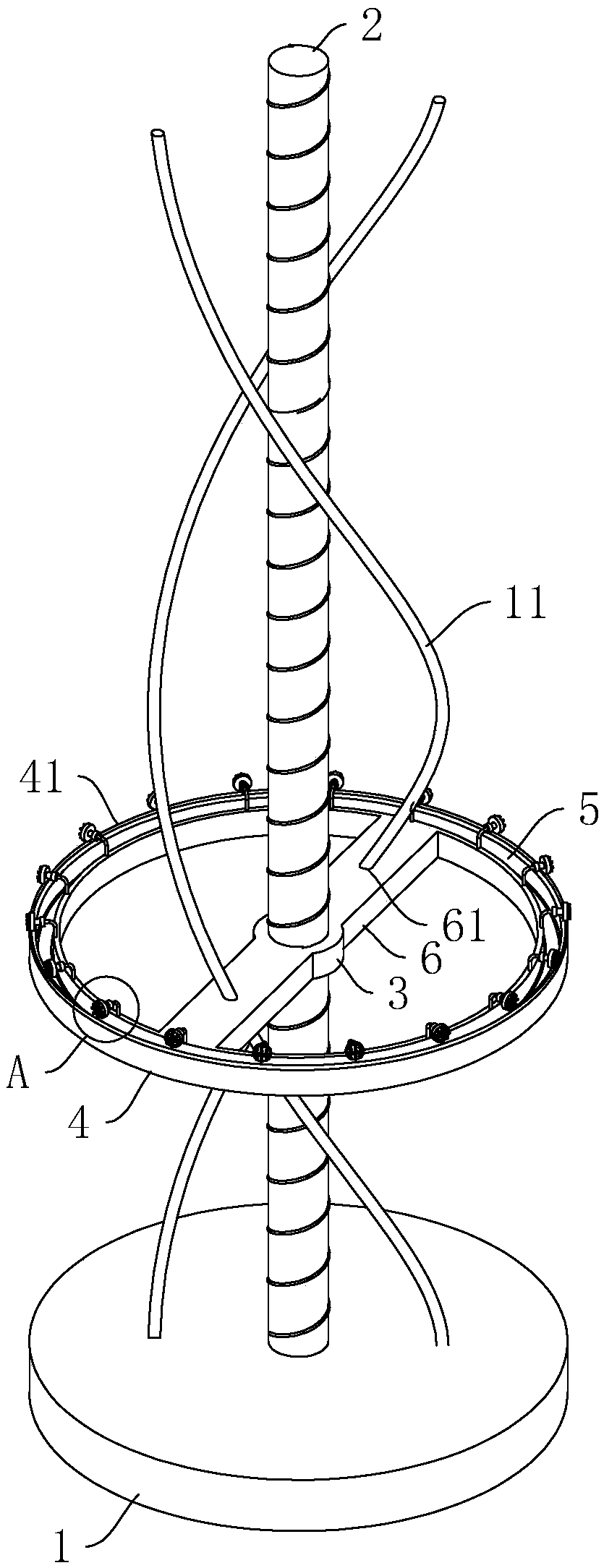

[0039] Such as figure 1 As shown, a boiler flue cleaning device includes a base 1, a transmission screw 2 vertically rotatably connected to the middle of the base 1, the outer wall of the transmission screw 2 is provided with a nut 3, and the screw and the nut 3 form a wire. pole vice.

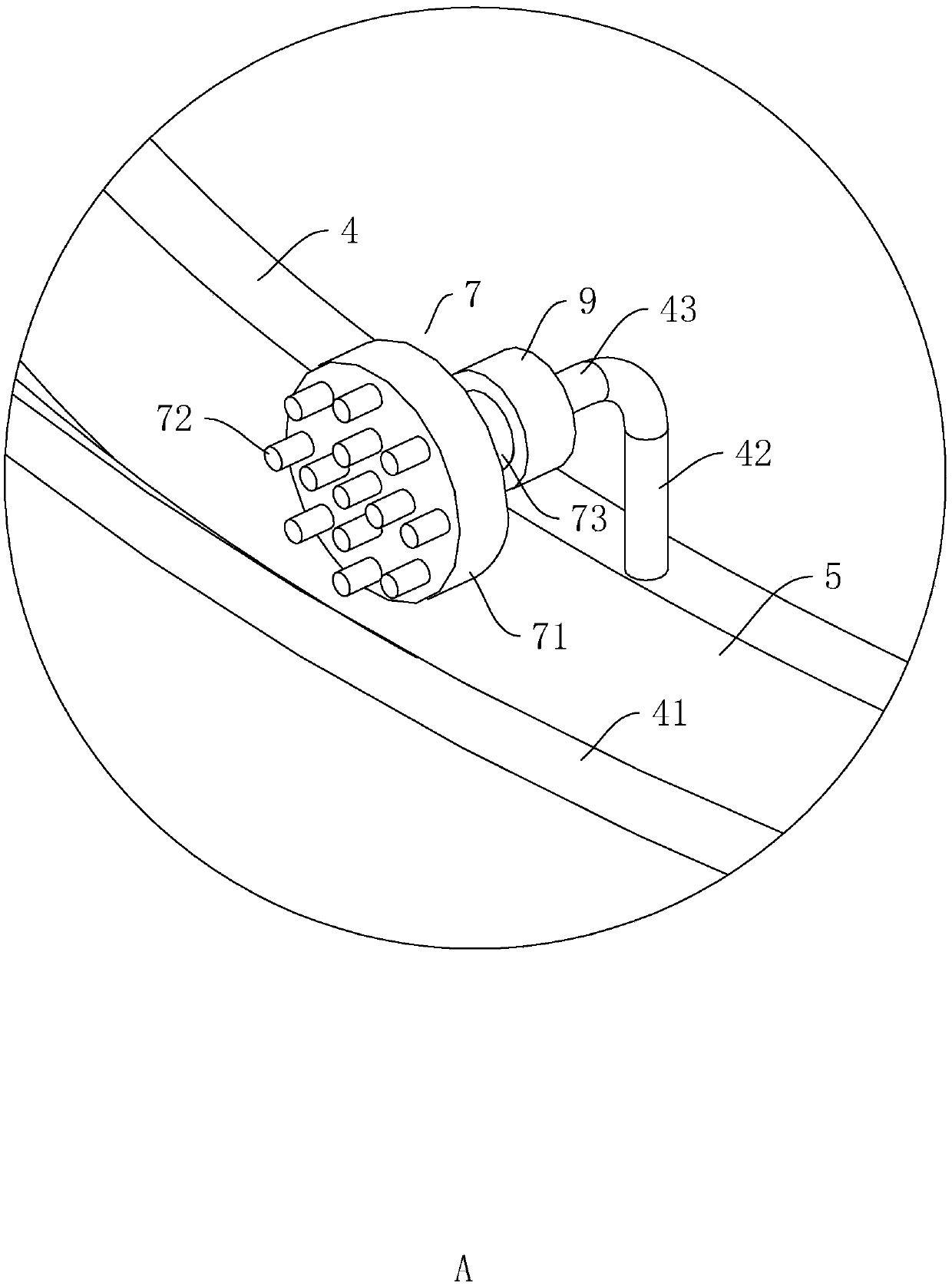

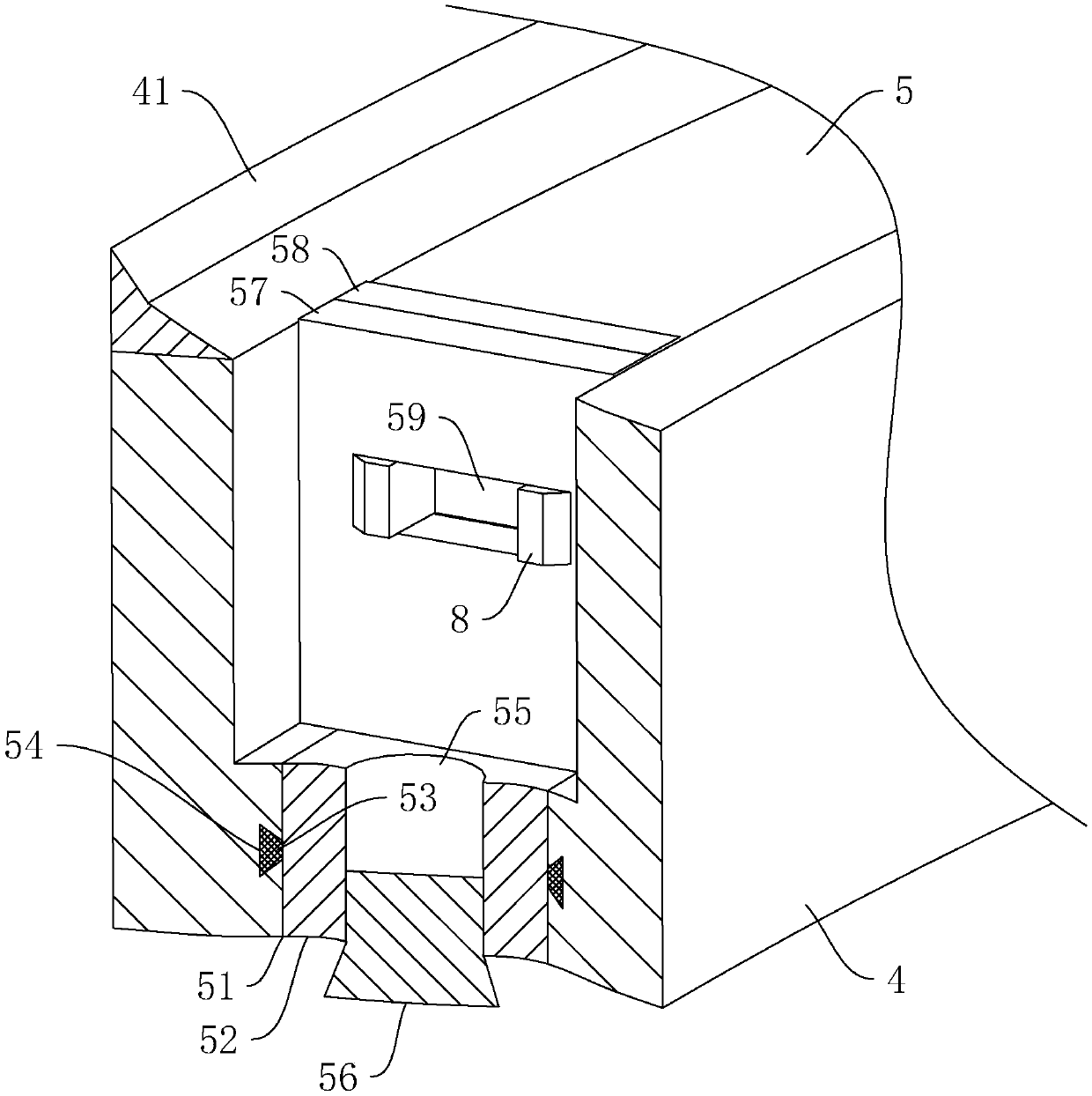

[0040] Such as figure 1 As shown, the device also includes a mounting ring 4 , and a ring of receiving grooves 5 is provided on the upper end surface of the mounting ring 4 . A pair of support plates 6 are arranged in front of the inner wall of the mounting ring 4 and the outer wall of the nut 3 , and the pair of support plates 6 are positioned opposite to each other. The upper end surface of the installation ring 4 is provided with a scraper 41 for abutting against the inside of the flue, and the scraper 41 is located at the outer edge of the installation ring 4 .

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com