Washing machine window pad and washing machine

A technology for washing machines and window mats, applied in the field of washing machines, can solve the problems of mold breeding and washing machine window mats being dirty, etc., and achieve the effect of improving experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

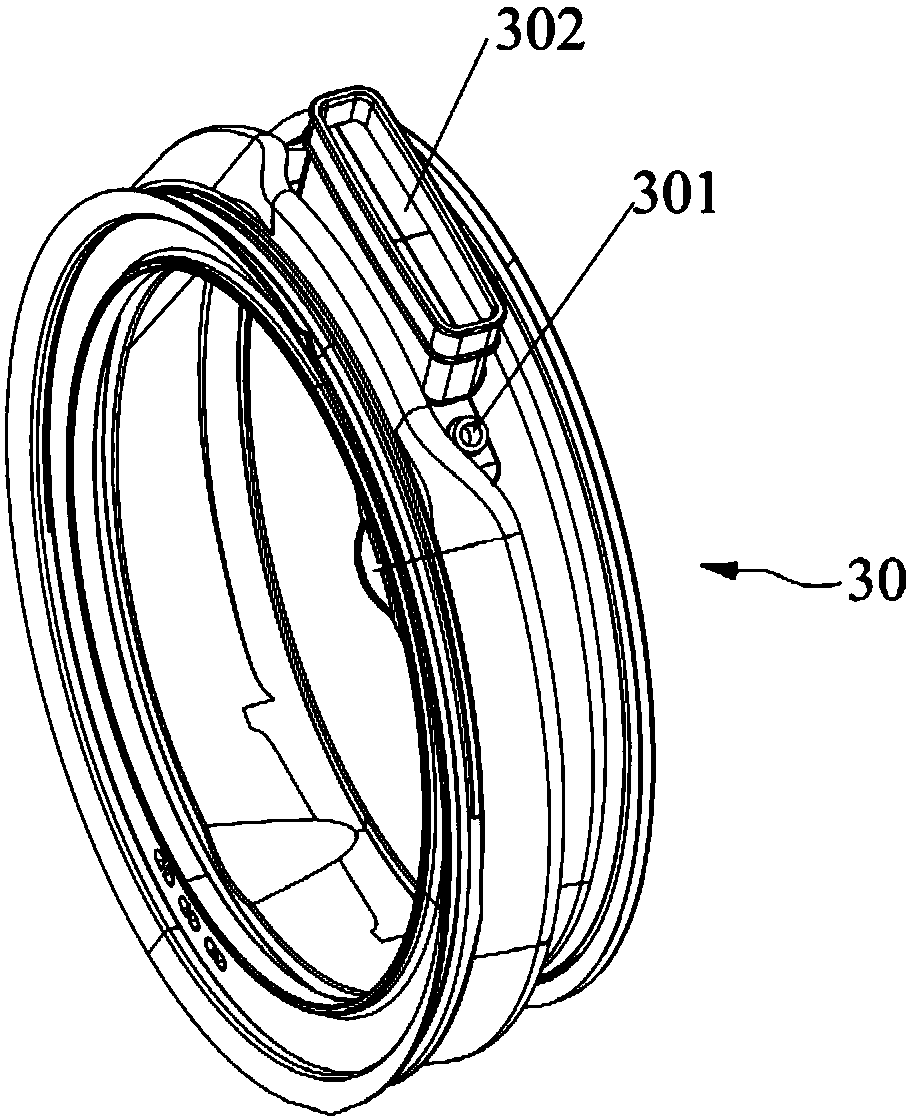

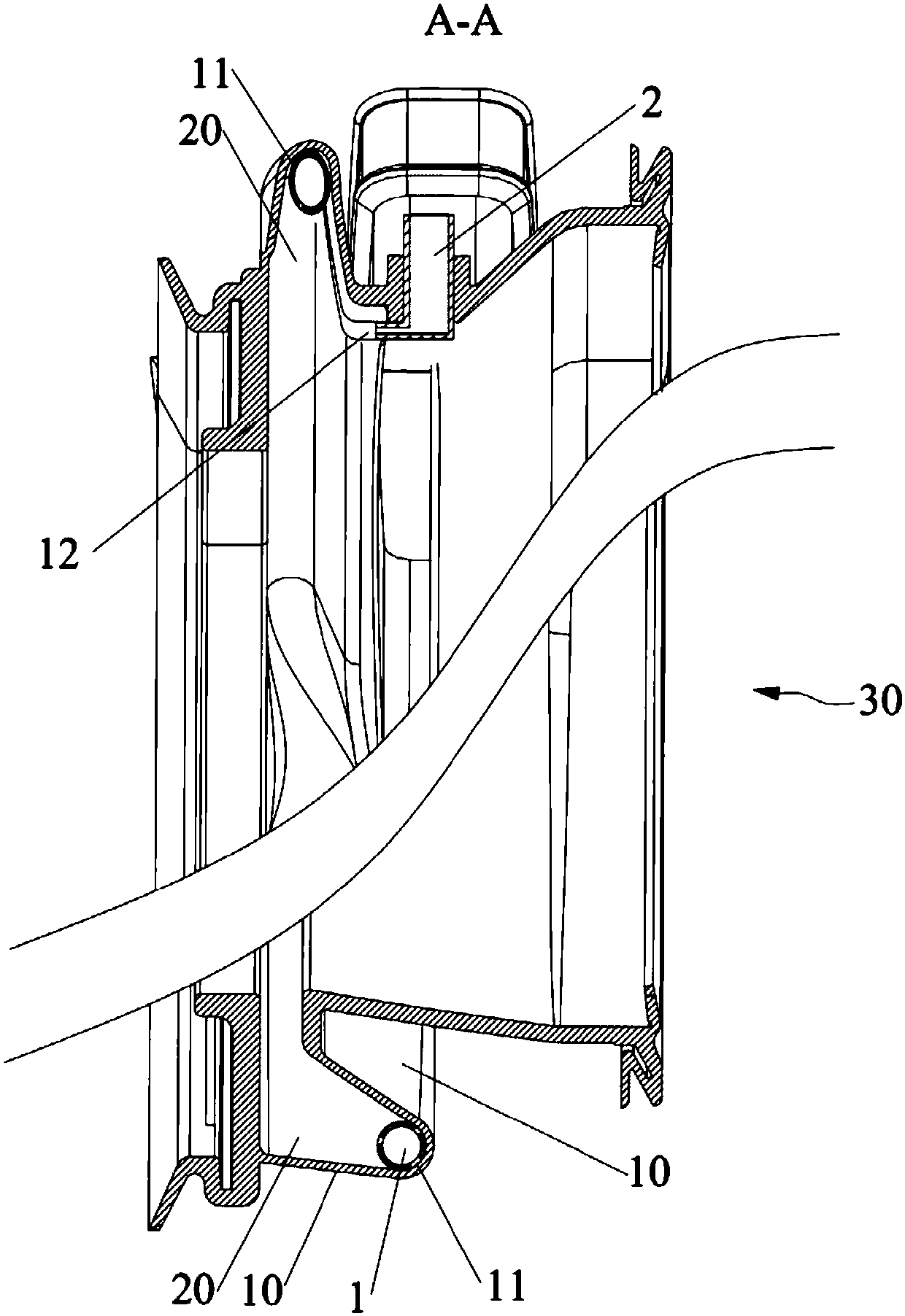

[0025] This embodiment provides a washing machine window pad, such as Figure 1-Figure 3 As shown, the washing machine window pad includes a spray part 1 arranged in the corrugated groove 20 formed by the folds of the window pad 10, the spray part 1 is an annular structure provided with a cavity, and the window pad 30 is provided with a water inlet pipe 2 , the spray part 1 is connected to the water inlet pipe 2 to spray and clean the corrugated groove 20 .

[0026] In this embodiment, the shower part 1 with a ring structure is arranged in the corrugated groove 20 formed by the window mat folds 10, and the spray part 1 is supplied with water through the water inlet pipe 2, thereby realizing the pairing of the corrugated groove by the spray part 1. 20, circular spraying is carried out, so that the window pad of the washing machine has a self-cleaning function, which avoids the time-consuming and laborious situation that the window pad of the washing machine in the prior art nee...

Embodiment 2

[0033] This embodiment also provides another structure of the shower part 1, such as Figure 4 As shown, the spraying part 1 is a special-shaped pipe adapted to the corrugated groove 20, and its circumferential direction is fitted with the corrugated groove 20, which can effectively prevent foreign matter residues from entering the corrugated groove 20, thereby avoiding the washing machine. The condition of the window mats was very dirty. At the same time, as the window pad folds 10 expand and contract, the spraying part 1 constantly rubs against the inner wall of the corrugated groove 20. Since the circumferential direction of the spraying part 1 fits with the corrugated groove 20, the friction area is increased, thereby further ensuring Cleaning effect of washing machine window mat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com