Gasoline engine lubricating oil composition and preparation method thereof

A lubricating oil composition and gasoline engine technology, applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of catalyst poisoning and restriction, and achieve the effects of prolonging service life and excellent anti-oxidation and anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0025] Preparation Example 1 Preparation of Antioxidant and Antiwear Agent

[0026] In a 250ml three-necked flask with a stirring device, add 141.6g (0.4mol) of diisooctyl dithiophosphoric acid, keep the temperature at 60°C, and add 5.7g of 30% hydrogen peroxide solution dropwise within 30 minutes (equivalent to hydrogen peroxide is 0.05 mol), continue to react for 2 hours after the dropwise addition, then raise the temperature to 70°C, add 13.4g (0.165mol) of zinc oxide, raise the temperature to 75-90°C and react for 3-5 hours, continue to heat up to 95-105°C, and depressurize The residual moisture was distilled off, and the antioxidant and anti-wear agent of the present invention was obtained by filtration, which was designated as sample 1.

preparation example 2-4

[0027] Preparation Example 2-4 Preparation of Antioxidant and Antiwear Agent

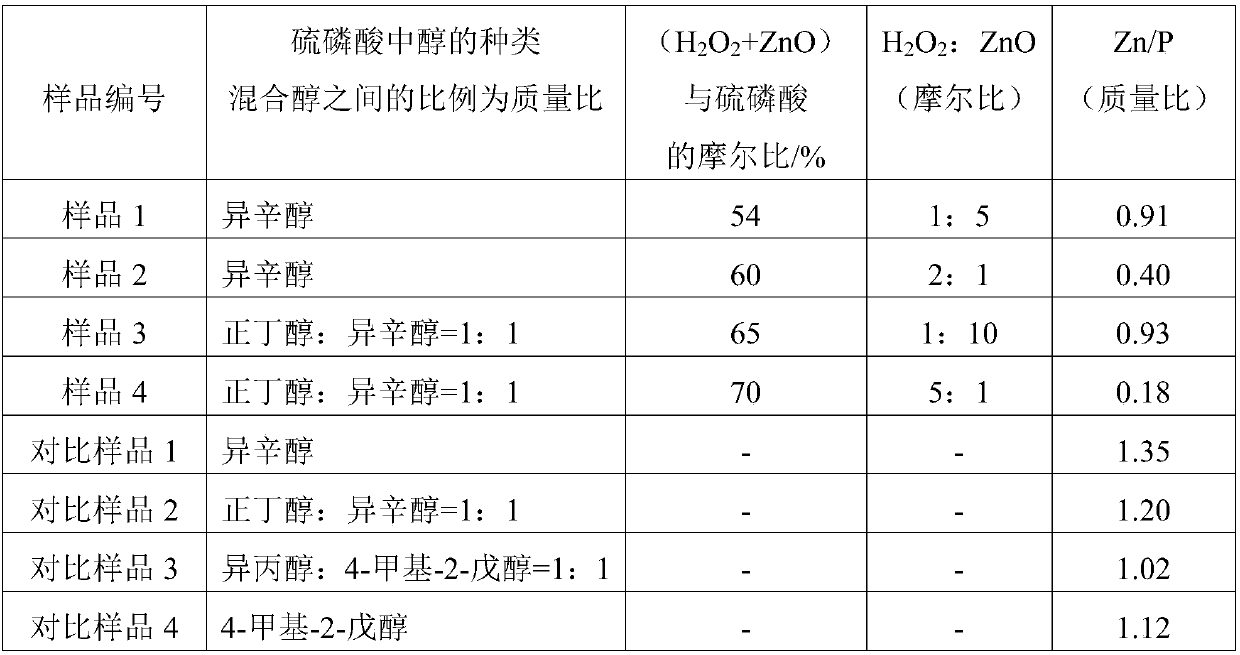

[0028] According to the method of Preparation Example 1, the antioxidant and anti-wear agent of the present invention is prepared by using sulfuric acid of different structures, different molar ratios of sulfuric acid to hydrogen peroxide, and different molar ratios of hydrogen peroxide to zinc oxide, which are respectively recorded as samples 2-4 , the reaction conditions are shown in Table 1.

[0029] Contrast Antioxidant and Antiwear Agents 1-4

[0030] Also listed comparative sample 1-4 in table 1, wherein comparative sample 1 is the zinc diisooctyl dithiophosphate (C8 primary alcohol ZDDP) of commercialization, domestic code name is T203; Comparative sample 2 is commercialized Butyl / isooctyl zinc dithiophosphate (C4 / C8 primary alcohol ZDDP), the domestic code is T202; comparative sample 3 is C3 / C6 secondary alcohol ZDDP, prepared according to the conventional ZDDP method; comparative sample 4 ...

Embodiment 1~4

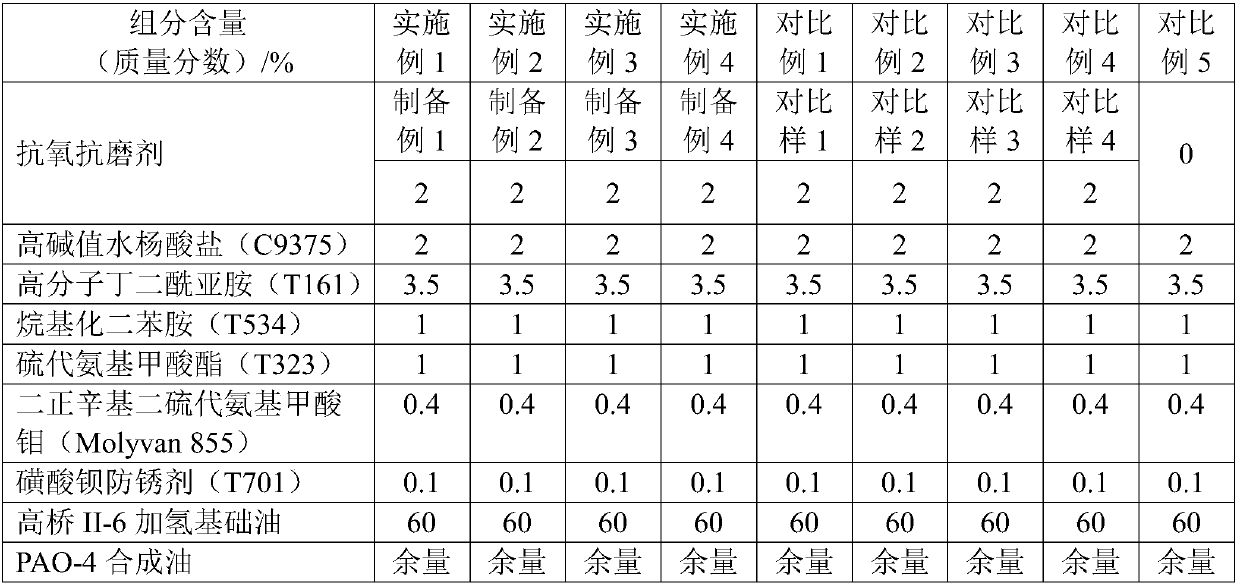

[0051] Embodiment 1~4 and comparative example 1~5

[0052] The antioxidant and antiwear agents of Preparation Examples 1 to 4 of the present invention and the other four comparative antioxidant and antiwear agents were mixed at 70°C for 1 hour according to the compositions and proportions in Table 2 to obtain the antioxidative and antiwear agents of Examples 1 to 4. Lubricating oil composition and the lubricating oil composition of Comparative Examples 1-4. Wherein, based on the total mass of the lubricating oil composition, the addition amount of the antioxidant and anti-wear agent is 2.0%. The oil sample without antiwear agent was taken as the blank sample, i.e. comparative example 5. Examples 1-4 and Comparative Examples 1-5 are the same except for the anti-wear agent. Comparative examples 6 and 7 are API SN refined oils sold on the market.

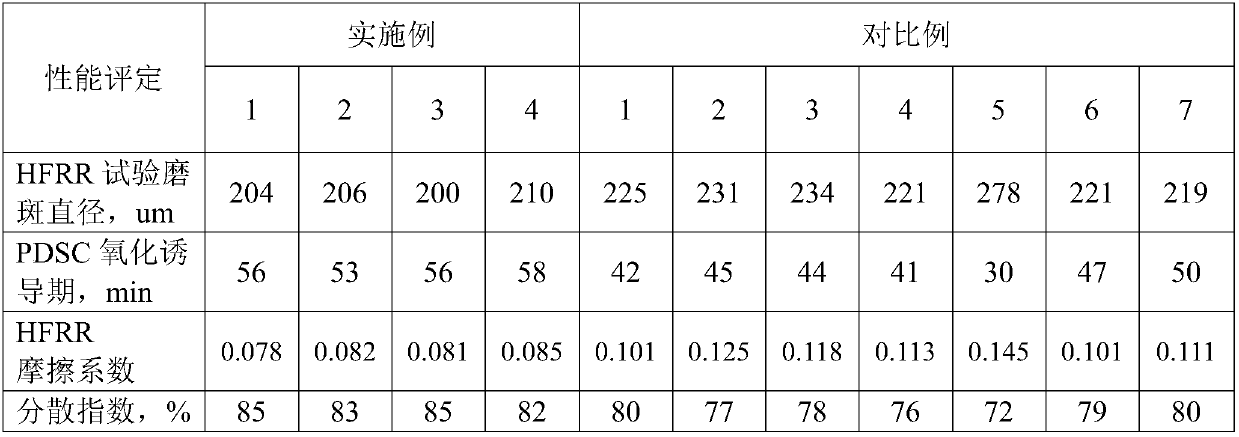

[0053] Using the lubricating oil compositions of Examples 1-4 and the lubricating oil compositions of Comparative Examples 1-7 as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com