Mold-proof, antibacterial and waterproof coating and preparation method thereof

A waterproof coating, anti-mildew and anti-bacterial technology, applied in anti-fouling/underwater coatings, cement coatings, coatings, etc., can solve the problems of moldy coatings, failure of waterproof coatings, and breeding of bacteria and fungi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

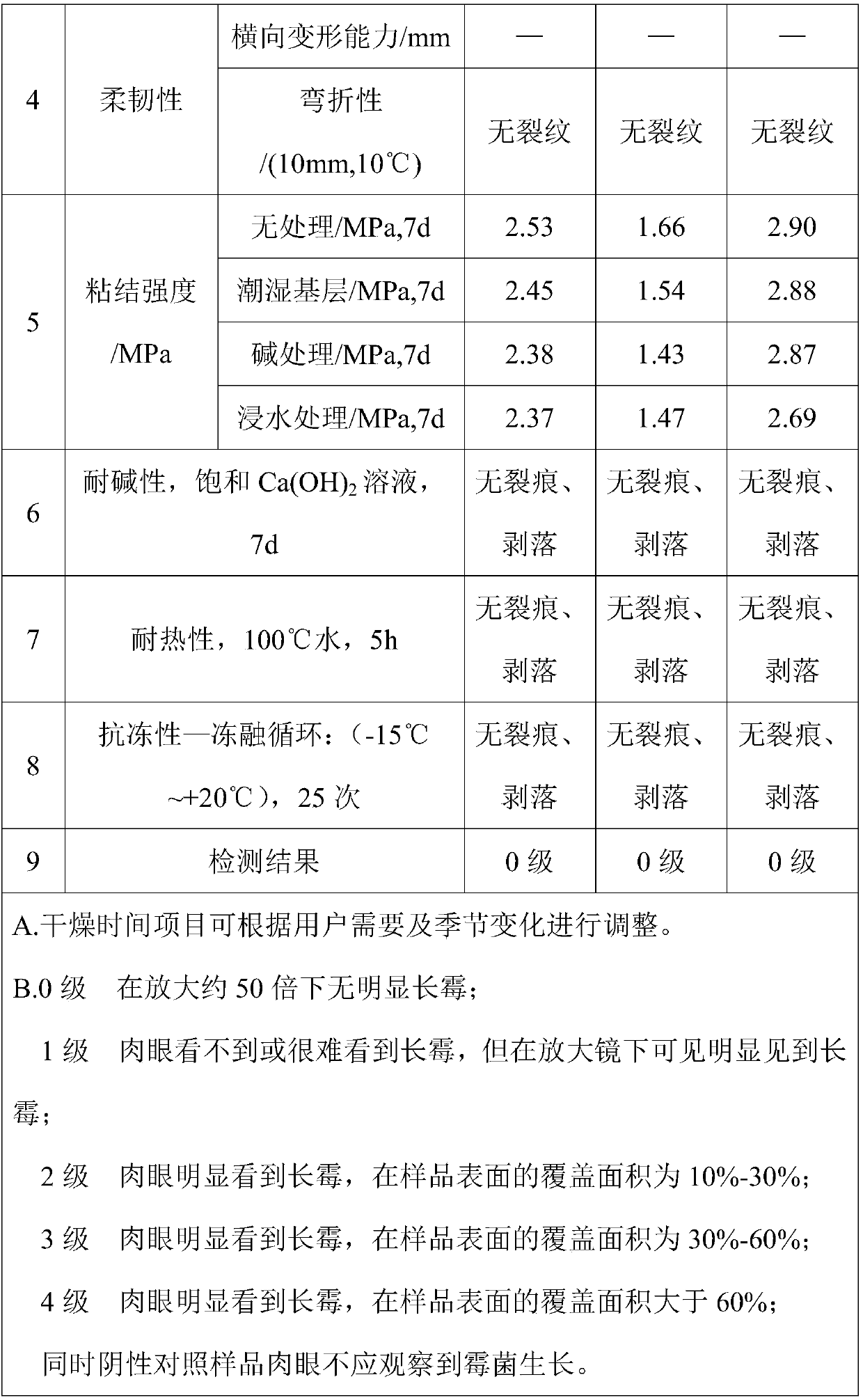

Embodiment 1

[0036] The antifungal, antibacterial, and waterproof coating described in this example, the formula is calculated by mass percentage, and consists of the following components, wherein the mass ratio of the added amounts of the two components is 1:4.0.

[0037] Liquid material composition: Propylene Emulsion No. 1 (RS-300SD) 20%, Propylene Emulsion No. 2 (BLJ-6088) 24.7%, wetting and dispersing agent (OROTAN 731A) 0.20%, defoamer (SN-DEFOAMER154 ) 0.10%, water 50%, copper sulfate pentahydrate 5%.

[0038] Powder composition: cement (No. 42.5 Portland cement) 45%, quartz sand (120 mesh) 49.58%, quartz powder (200 mesh) 3%, cellulose ether (MH60001P6) 0.02%, water reducer (F10 ) 0.4%, microsilica fume 1%, inorganic silver ion antibacterial agent (IONPURE) 1%.

[0039] In this embodiment, each component is prepared according to the following steps:

[0040] (1) The preparation of the liquid material component, according to the formula quantity, copper sulfate pentahydrate and wa...

Embodiment 2

[0045] The antifungal, antibacterial, and waterproof coating described in this example, the formula is calculated by mass percentage, and consists of the following components, wherein the mass ratio of the added amounts of the two components is 1:3.0.

[0046]Liquid material composition: Propylene Emulsion No. 1 (RS-300SD) 24.75%, Propylene Emulsion No. 2 (BLJ-6088) 24.75%, wetting and dispersing agent (OROTAN 731A) 0.30%, defoamer (SN-DEFOAMER154 ) 0.20%, water 40%, copper sulfate pentahydrate 10%.

[0047] Powder composition: cement (No. 42.5 silicate) 55%, quartz sand (120 mesh) 35.45%, quartz powder (200 mesh) 5%, cellulose ether (MH60001P6) 0.05%, water reducer (F10) 0.5%, microsilica fume 2%, inorganic silver ion antibacterial agent (IONPURE) 2%.

[0048] In this embodiment, each component is prepared according to the following steps:

[0049] (1) The preparation of the liquid material component, according to the formula quantity, copper sulfate pentahydrate and water ...

Embodiment 3

[0054] The antifungal, antibacterial, and waterproof coating described in this example, the formula is calculated by mass percentage, and consists of the following components, wherein the mass ratio of the added amounts of the two components is 1:3.8.

[0055] Liquid material composition: Propylene Emulsion No. 1 (RS-300SD) 25%, Propylene Emulsion No. 2 (BLJ-6088) 25%, wetting and dispersing agent (OROTAN 731A) 0.25%, defoamer (SN-DEFOAMER154 ) 0.15%, water 42.1%, copper sulfate pentahydrate 7.5%.

[0056] Powder composition: cement (No. 42.5 silicate) 50%, quartz sand (120 mesh) 42.5%, quartz powder (200 mesh) 4%, cellulose ether (MH60001P6) 0.05%, water reducer (F10) 0.45%, microsilica fume 1.5%, inorganic silver ion antibacterial agent (IONPURE) 1.5%.

[0057] In this embodiment, each component is prepared according to the following steps:

[0058] (1) The preparation of the liquid material component, according to the formula quantity, copper sulfate pentahydrate and wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com