Preparation of a phosphorus-magnesium composite flame retardant and its application in the preparation of flame retardant copolyester materials

A compound flame retardant, flame retardant copolyester technology, applied in the fields of polymer materials and flame retardant materials, can solve the problems of scalding, poor thermal stability, high price, reduce dosage, improve flame retardant performance and mechanical performance, Enhanced thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

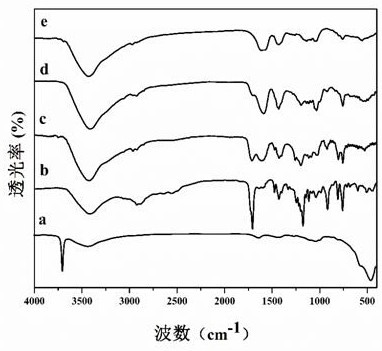

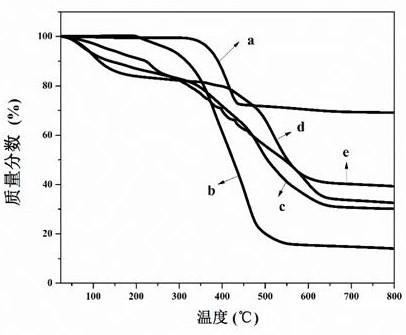

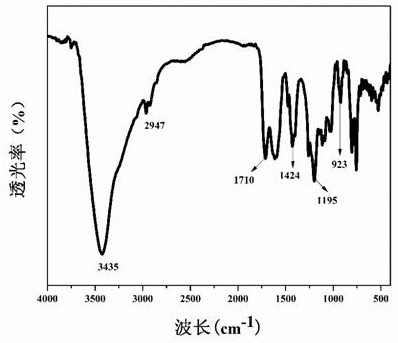

[0032] (1) Preparation of phosphorus-magnesium flame retardant: Weigh 10g of 2-carboxyethyl-phenylphosphinic acid, dissolve it in a mixed solution of 200mL distilled water and 200mL absolute ethanol, heat up to 60°C, add 4g hydrotalcite, and continue React for 4 hours; remove the distilled water after the reaction, and dry under vacuum at 80°C to obtain a phosphorus-magnesium flame retardant;

[0033] (2) Preparation of phosphorus-magnesium flame-retardant copolyester composite material: Take 403.4g of ethylene glycol, 830.6g of terephthalic acid, and 0.29g of antimony trioxide, and add them to a 1.5L reaction kettle, and then add 6.2g Phosphorus-magnesium flame retardant, check the airtightness of the system, pass in nitrogen to discharge the air in the kettle, and carry out esterification reaction at a temperature of 220°C and a pressure of 0.2MPa. When the column top temperature is lower than 100°C, after the esterification is complete, the system enters the vacuum polyconden...

Embodiment 2

[0036] (1) Preparation of phosphorus-magnesium flame retardant: Take 47g of 9,10-dihydro-9-oxa-10-phosphophenanthrene-succinic acid, dissolve it in a mixed solution of 400mL distilled water and 400mL absolute ethanol, Raise the temperature to 65°C, add 4g of magnesium hydroxide, and continue the reaction for 2 hours; after the reaction, remove the distilled water and dry under vacuum at 80°C to obtain a phosphorus-magnesium flame retardant;

[0037] (2) Preparation of phosphorus-magnesium flame-retardant copolyester composite material: Take 403.4g of ethylene glycol, 830.6g of terephthalic acid, and 0.29g of antimony trioxide, and add them to a 1.5L reaction kettle, and then add 12.3g Phosphorus-magnesium flame retardant, check the airtightness of the system, let in nitrogen to discharge the air in the kettle; carry out the esterification reaction at a temperature of 230°C and a pressure of 0.25MPa. When the column top temperature is lower than 100°C, after the esterification ...

Embodiment 3

[0040] (1) Preparation of phosphorus-magnesium flame retardant: Take 30g of aminotrimethylene phosphonic acid, dissolve it in a mixed solution of 250mL of distilled water and 250mL of absolute ethanol, raise the temperature to 70°C, then add 8g of magnesium hydroxide, and continue the reaction for 4h After the reaction, the distilled water was removed and dried under vacuum at 80°C to obtain a phosphorus-magnesium flame retardant;

[0041] (2) Preparation of flame-retardant copolyester composite material: Take 403.4g of ethylene glycol, 830.6g of terephthalic acid, and 0.29g of antimony trioxide, and add them to a 1.5L reaction kettle, and then add 18.5g of phosphorus-magnesium Flame retardant, check the airtightness of the system, pass in nitrogen to discharge the air in the kettle, and carry out esterification reaction at a temperature of 235°C and a pressure of 0.3MPa. When the column top temperature is lower than 100°C, after the esterification is complete, the system ente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| peak heat release rate | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com