Thermoprinting and stitching method for bedsheet

A bed sheet and suture technology, applied in the direction of bed sheets, blankets, etc., can solve the problems of the suture line off-line gap, affect the aesthetics, low strength, etc., and achieve the effect of improving the stitching strength, improving the hot stamping quality, and improving the toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings.

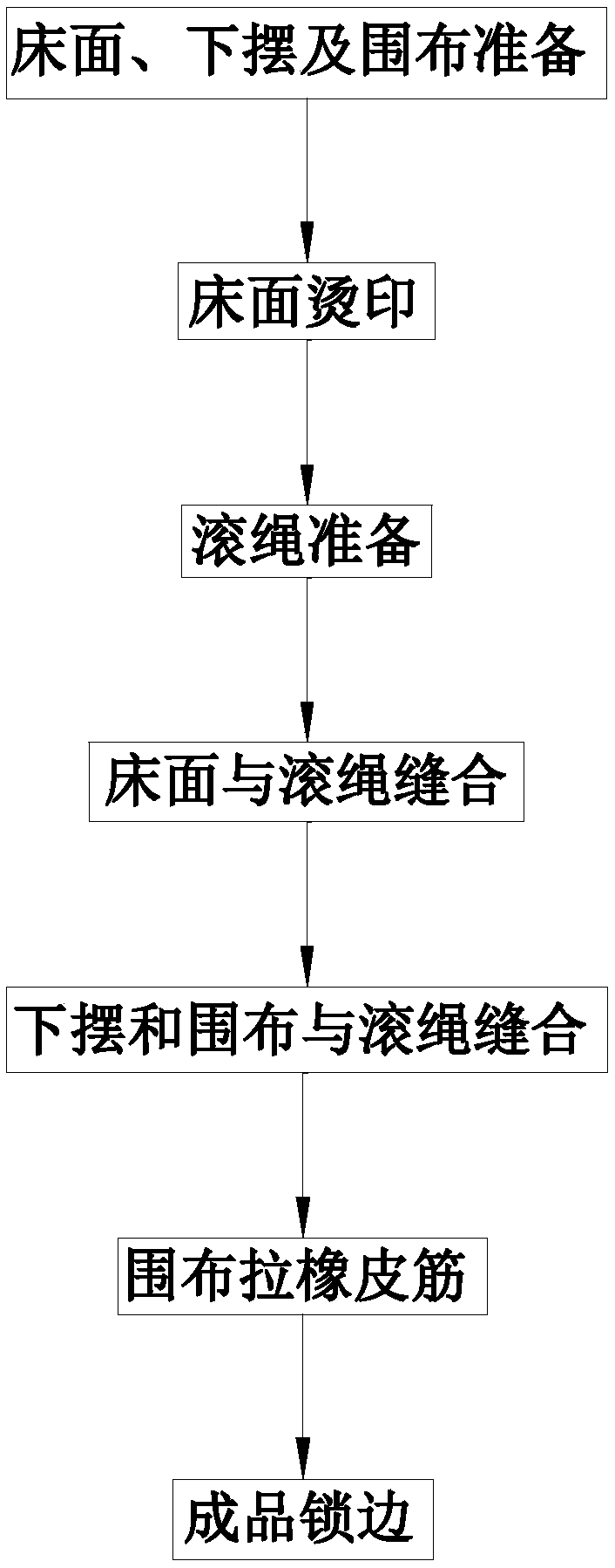

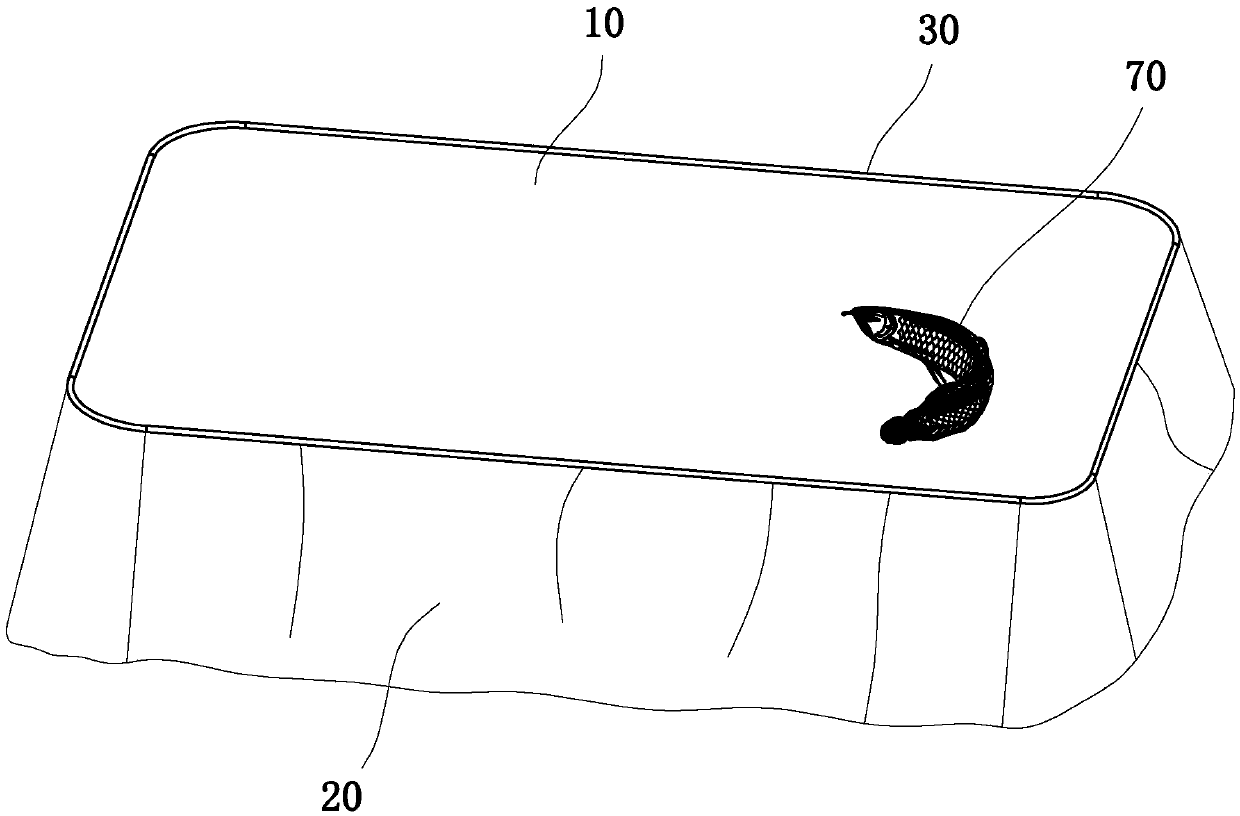

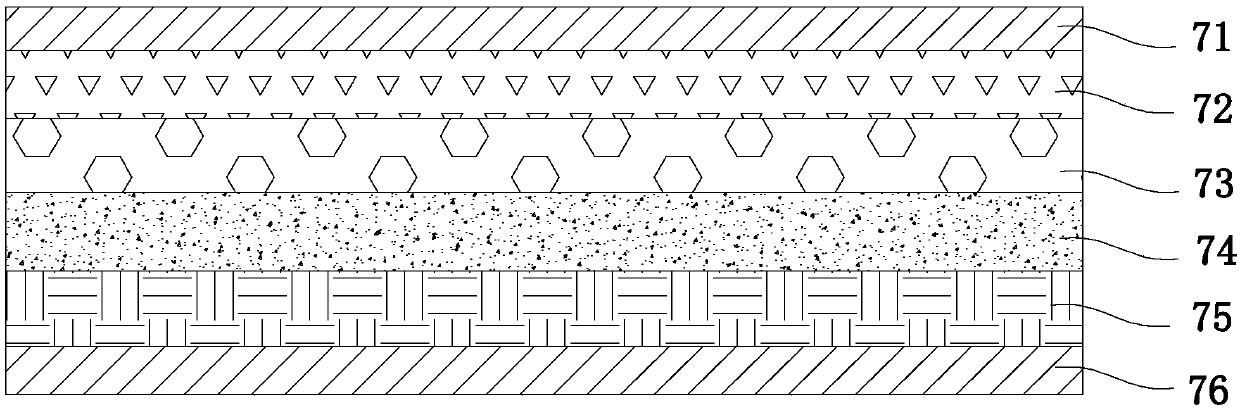

[0048] refer to figure 1 , a sewing method for a bed sheet, the structure of the bed sheet after sewing is as follows figure 2 Shown includes a split bed top 10 , a hem 20 adjacent to the bed top 10 , a wrap 40 connected to the inner side of the bottom 20 , and a rolling rope 30 connecting the bed top 10 , the bottom 20 and the wrap 40 . The rolling rope 30 is enclosed around the bed surface 10, and the shape and area of the bed surface 10 can be set to coincide with the upper surface of the mattress to be laid, and then the bed surface 10 can cover the whole mattress. At the same time, the bed surface 10 is woven from warp threads and weft threads, wherein the warp threads are polyester threads, and the weft threads are regenerated fibers.

[0049] The specific suturing method includes the following steps:

[0050] Step 1, bed surface, hem and cloth pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com