Preparation method of latex plugging agent for drilling fluids, and drilling fluid

A technology of drilling fluid and plugging agent, which is applied in the preparation of latex plugging agent for drilling fluid and in the field of drilling fluid, which can solve the problems of easy foaming, poor stability, and easy demulsification, etc., achieve long stable period and reduce foaming Sex, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

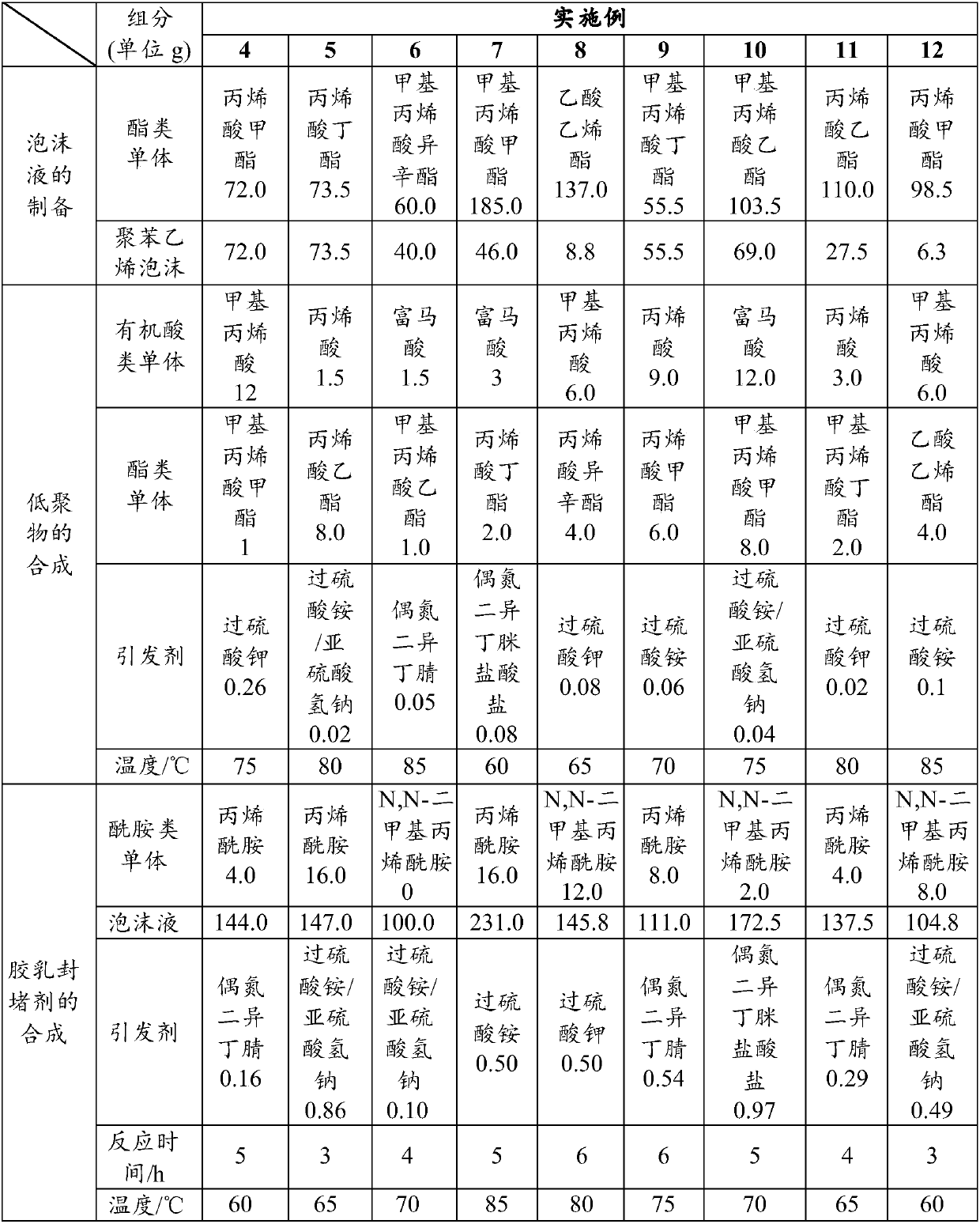

Examples

Embodiment 1

[0034] In parts by weight, 55.0 parts of polystyrene foam was pulverized, dissolved in 83.0 parts of ethyl acrylate under stirring, and mixed uniformly to obtain a foam liquid.

[0035]Weigh 184.0 parts of deionized water, 9.0 parts of acrylic acid, and 2.0 parts of vinyl acetate, stir and heat, when the temperature rises to 60°C, add 0.26 parts of azobisisobutyronitrile, the temperature rises to 80°C, and keep for 1 to 2 hours , the reaction system was neutralized to 7-8 with NaOH to obtain oligomers.

[0036] Cool down the oligomer system, add 2.0 parts of acrylamide aqueous solution under stirring, slowly add 138.0 parts of foam liquid dropwise, continue to stir and heat, when the temperature rises to 75°C, add 0.30 parts of azobisisobutyramidine salt The acid solution was incubated for 3 hours to terminate the reaction to obtain a soap-free latex plugging agent.

Embodiment 2

[0038] In parts by weight, 17.0 parts of polystyrene foam was pulverized, dissolved in 68.0 parts of butyl methacrylate under stirring, and mixed uniformly to obtain a foam liquid.

[0039] Weigh 155.0 parts of deionized water, 6.0 parts of methacrylic acid, and 4.0 parts of butyl methacrylate, stir and heat, when the temperature rises to 65°C, add 0.08 parts of ammonium persulfate, the temperature rises to 80°C, and keep the temperature for 1~ In 2h, the reaction system was neutralized to 7-8 with KOH to obtain oligomers.

[0040] Cool down the oligomer system, under stirring, add 8.0 parts of N,N-dimethylacrylamide aqueous solution, slowly add 85.0 parts of foam liquid dropwise, continue stirring and heating, when the temperature rises to 65 ° C, add 0.31 parts Potassium persulfate solution, the temperature was raised to 80°C, and the temperature was maintained for 4 hours to terminate the reaction to obtain a soap-free latex plugging agent.

Embodiment 3

[0042] In parts by weight, 8.0 parts of polystyrene foam was pulverized, dissolved in 125 parts of ethyl methacrylate under stirring, and mixed uniformly to obtain a foam liquid.

[0043] Weigh 286.0 parts of deionized water, 3.0 parts of fumaric acid, 6.0 parts of methyl acrylate, stir and heat, when the temperature rises to 70°C, add 0.036 parts of azobisisobutyramidine hydrochloride, and the temperature rises to 80°C , keep the temperature for 1~2h, and neutralize the reaction system to 7~8 with NaOH to obtain oligomer.

[0044] Cool down the oligomer system, under stirring, add 12.0 parts of acrylamide aqueous solution, slowly add 133.0 parts of foam liquid dropwise, continue to stir and heat, when the temperature rises to 85 ℃, add 0.62 parts of ammonium persulfate solution, the temperature rises. At 80°C, the temperature was kept for 6 hours, the reaction was terminated, and a soap-free latex plugging agent was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com