Fixture structure

A side wall and arc angle technology, applied in the field of fixtures, can solve the problems of not being able to meet the design trend of four-sided curved glass, not easy to form, and prone to wrinkles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

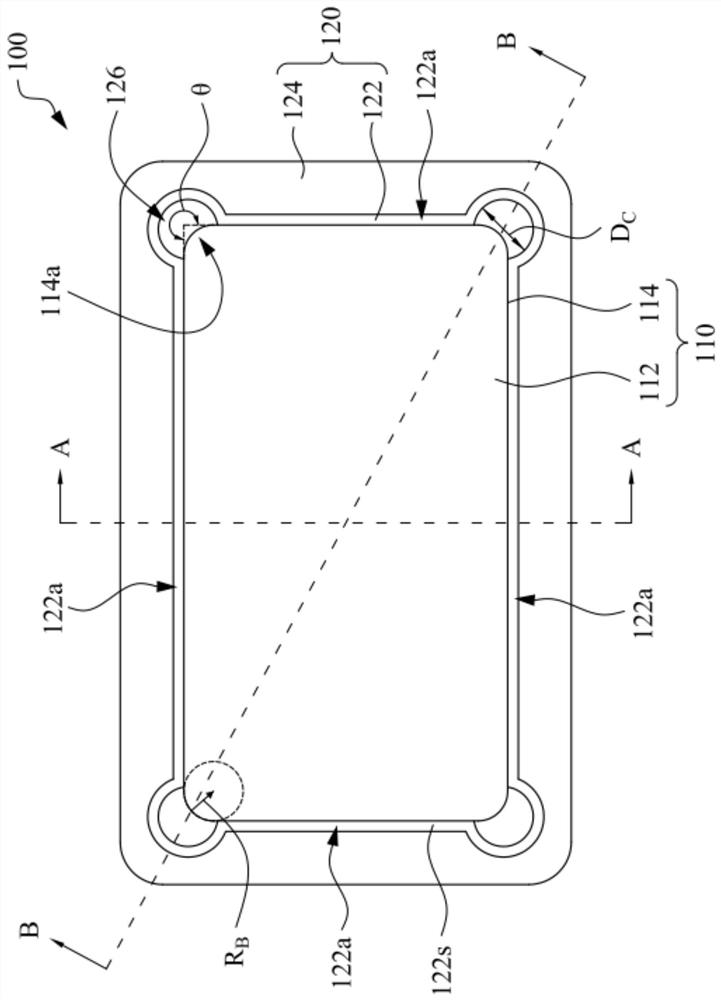

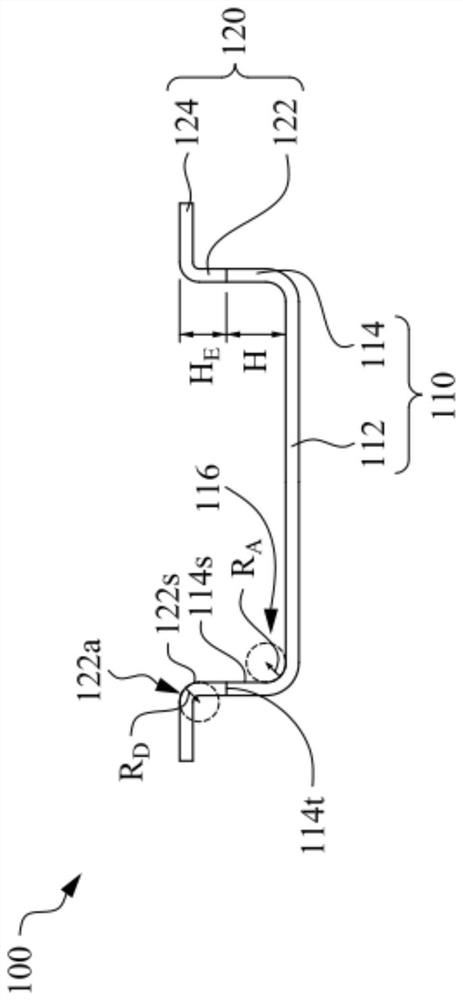

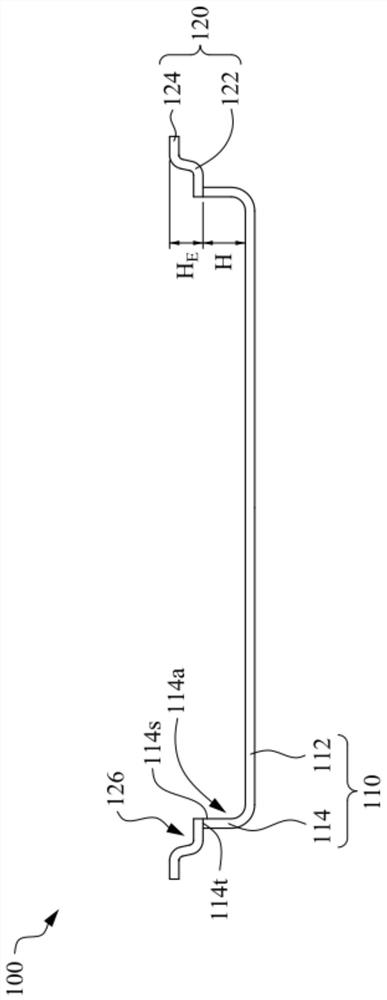

[0029] The jig structure 100 of this embodiment can be used for thermoforming a film, such as four-curved surface thermoforming. For example, the film base material that can be used for thermoforming processing can be a material with low dielectric constant, high light transmission and other properties suitable for touch sensing films, such as polyethylene terephthalate (PET), Cycloolefin polymer (COP), and polymethyl methacrylate (PMMA), etc.

[0030] Such as figure 1 and figure 2 As shown, in some embodiments, the jig structure 100 mainly includes a main body 110 and a spacer 120 . The internal shape and size of the main body 110 match the shape of the film to be formed. The main body 110 mainly includes a bottom plate 112 and a first side wall 114 , wherein the bottom plate 112 may have a square or rectangular plate-like structure. The first side wall 114 is erected on the edge of the bottom plate 112 and surrounds the bottom plate 112 in a peripheral manner. The mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com