Laminated structure solid-phase additive manufacturing method

A technology of additive manufacturing and laminated structure, which is applied in the field of additive manufacturing, can solve the problems of high cost of thin strips, achieve the effect of improving lap joints and optimizing the solid phase additive process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the present invention easier to understand, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

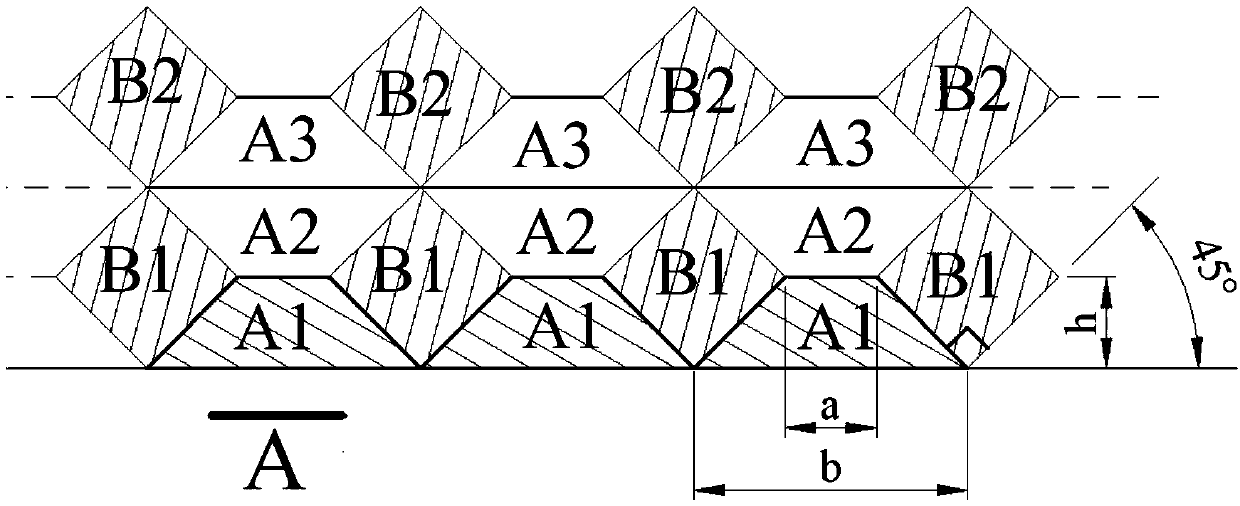

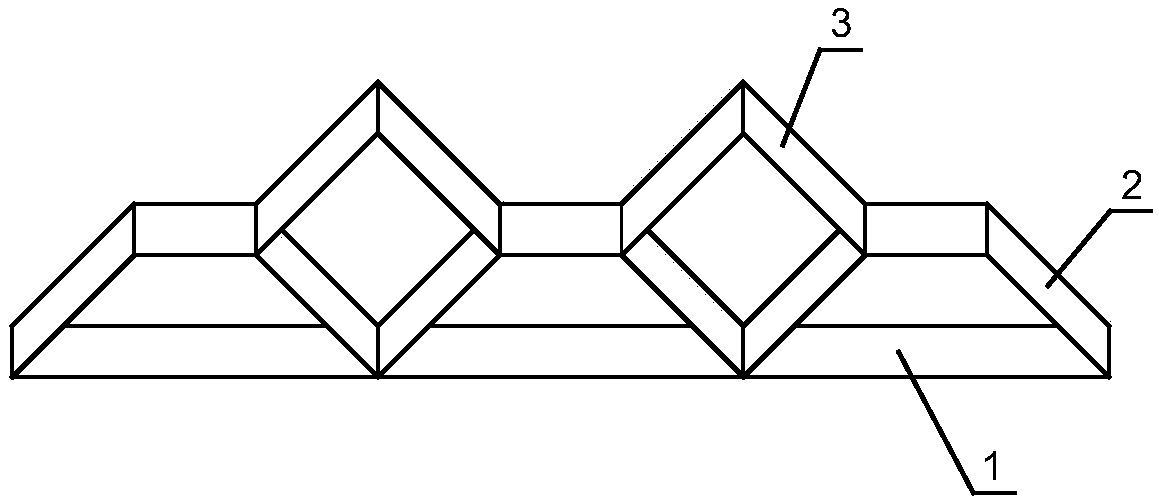

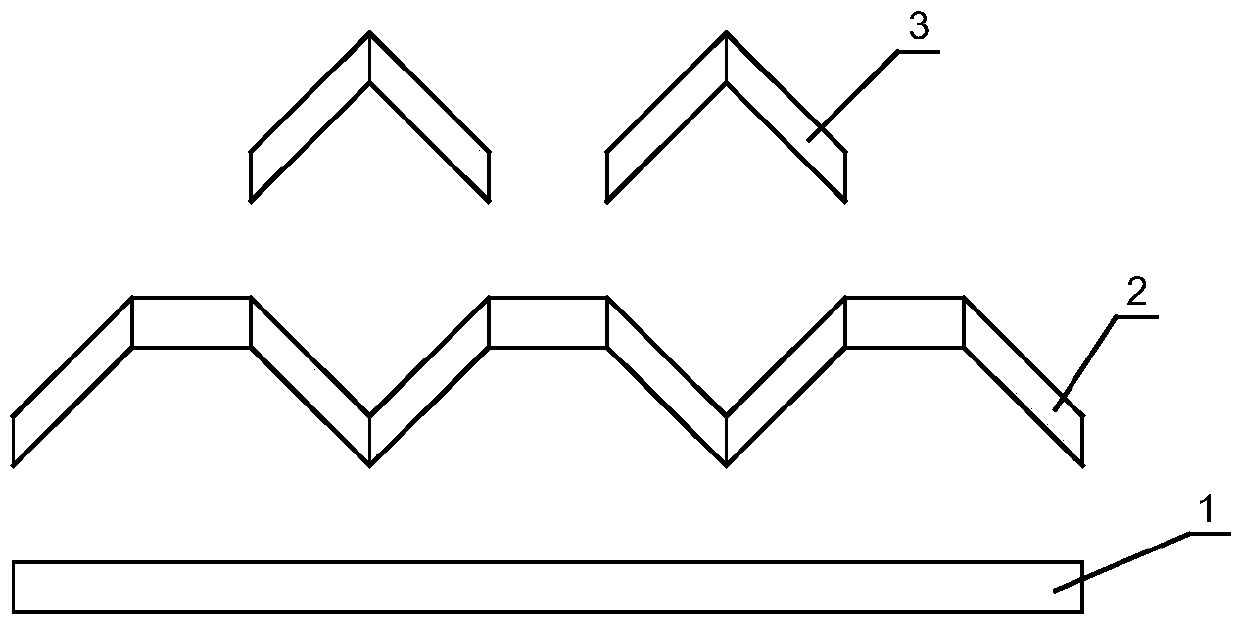

[0025] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 As shown, a solid-phase additive manufacturing method of a laminated structure of the present invention adopts molds corresponding to square and isosceles trapezoidal shapes, and alternately fills in and interpolates the blanks during the molding process of raw materials, so that the raw materials are formed layer by layer to form trapezoidal, square, Inverted trapezoidal, trapezoidal, sequentially reciprocating to add materials, the raw material is columnar wire; figure 1 shows a schematic diagram of the principle of a laminated structure solid-phase additive manufacturing overlapping method according to the present invention, wherein accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com