A kind of composite nanofiltration membrane and preparation method thereof

A technology of composite nanofiltration membrane and base membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

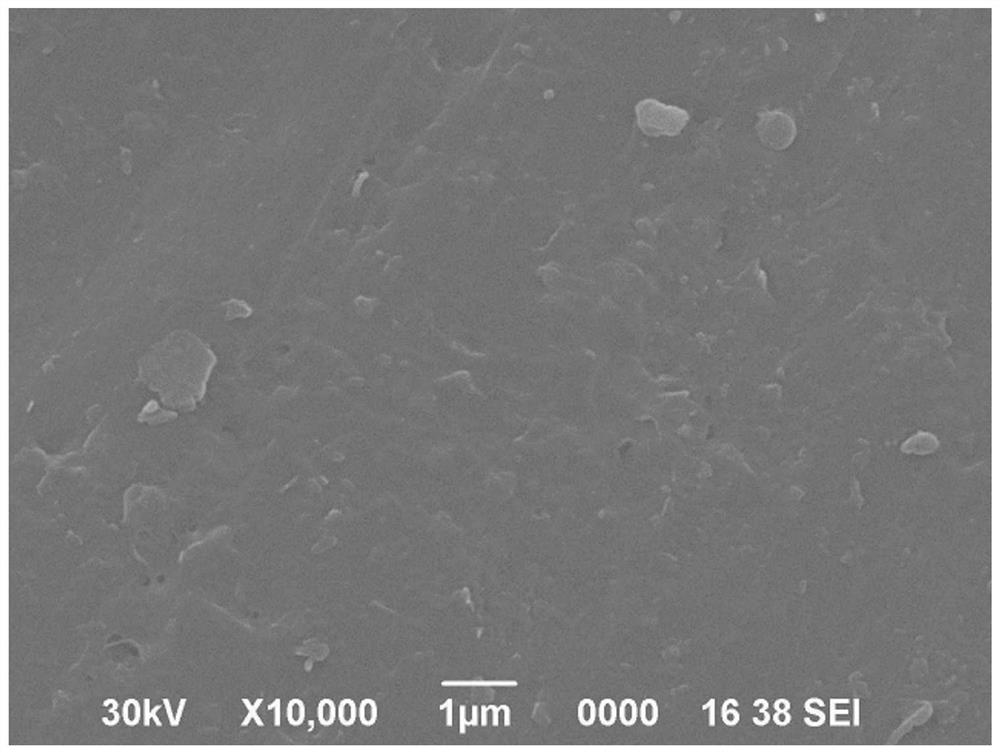

Image

Examples

preparation example Construction

[0076] (1) Preparation of modified meta-aramid polymer

[0077] Under nitrogen protection, add 80.383mL of DMAc solvent, 0.077mol of m-phenylenediamine, 0.0616mol of APBIA and 0.0154mol of 4-fluoro-1,3-phenylenediamine into a 1L four-necked flask equipped with mechanical stirring and a thermometer. Stir under nitrogen protection until the solute is completely dissolved. Use a freezing bath to adjust the reaction temperature to -15°C, add 0.1155mol of isophthaloyl chloride under stirring, control the reaction temperature of the reaction system below 0°C, and continue to add 0.0262mol of isophthaloyl dimethanol after reacting until the viscosity of the system is stable Acyl chloride, after the reaction until the viscosity of the system is stable, add 0.0123mol of isophthaloyl chloride at the end, the solution starts to thicken, the temperature rises, adjust the stirring speed to control the reaction temperature below 60°C until the reaction is complete, after adding 0.154mol of ...

Embodiment 1

[0104] (1) Prepare an aqueous solution: mix piperazine monomer (PIP), 2,5-diaminotrifluorobenzene monomer, SDS and triethylamine into deionized water to prepare an aqueous solution. In this aqueous solution, the content of piperazine monomer is 0.5% (w / v), the content of 2,5-diaminotrifluorobenzene monomer is 0.025% (w / v), and the content of SDS is 0.06% (w / v). v), the content of triethylamine is 0.2% (w / v).

[0105] (2) Preparation of organic solution: adding trimesoyl chloride into n-hexane to prepare an organic solution. The content of trimesoyl chloride in the organic solution was 0.3% (w / v).

[0106] (3) Immerse the modified meta-aramid hollow fiber base membrane in the aqueous solution, take it out after 1 minute, and dry it for 15 minutes after taking it out.

[0107] (4) Immerse the dried basement film in step (3) into an organic solution for interfacial polymerization, take it out after 1 minute, and dry it for 5 minutes after taking it out.

[0108] (5) heat-treat...

Embodiment 2

[0110] Except that the content of piperazine monomer in the aqueous solution was changed to 1% (w / v), other experimental conditions were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com