Processing simulation display device and processing simulation display method

A display device and display method technology, applied in the direction of comprehensive factory control, program control, instruments, etc., can solve the problems of complexity, inability to master complex tool movement, difficulty in verification operations, etc., and achieve an easy-to-master effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

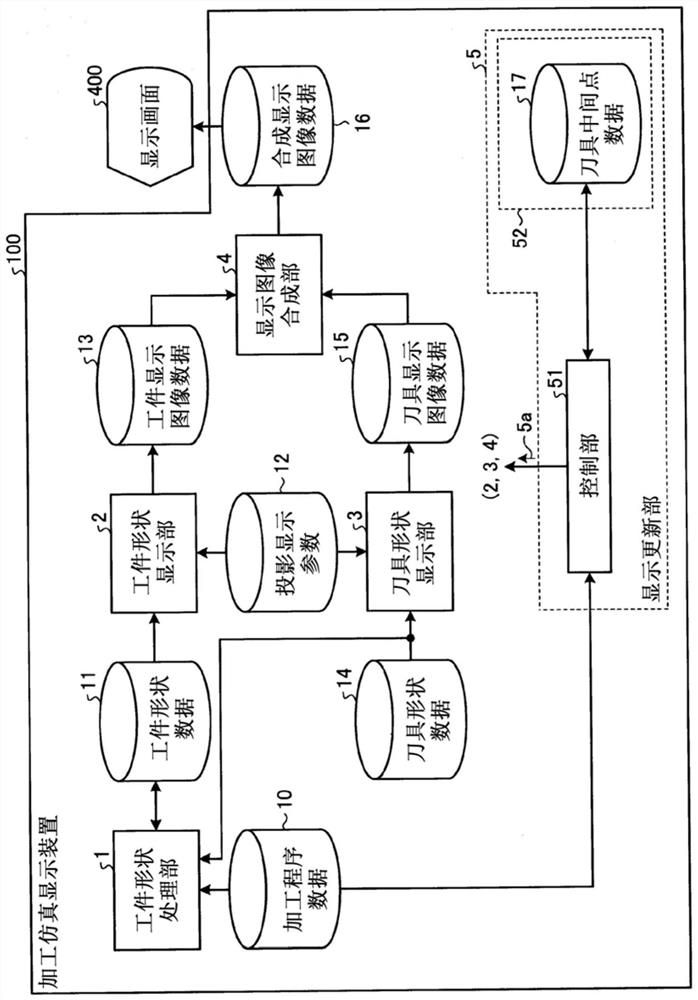

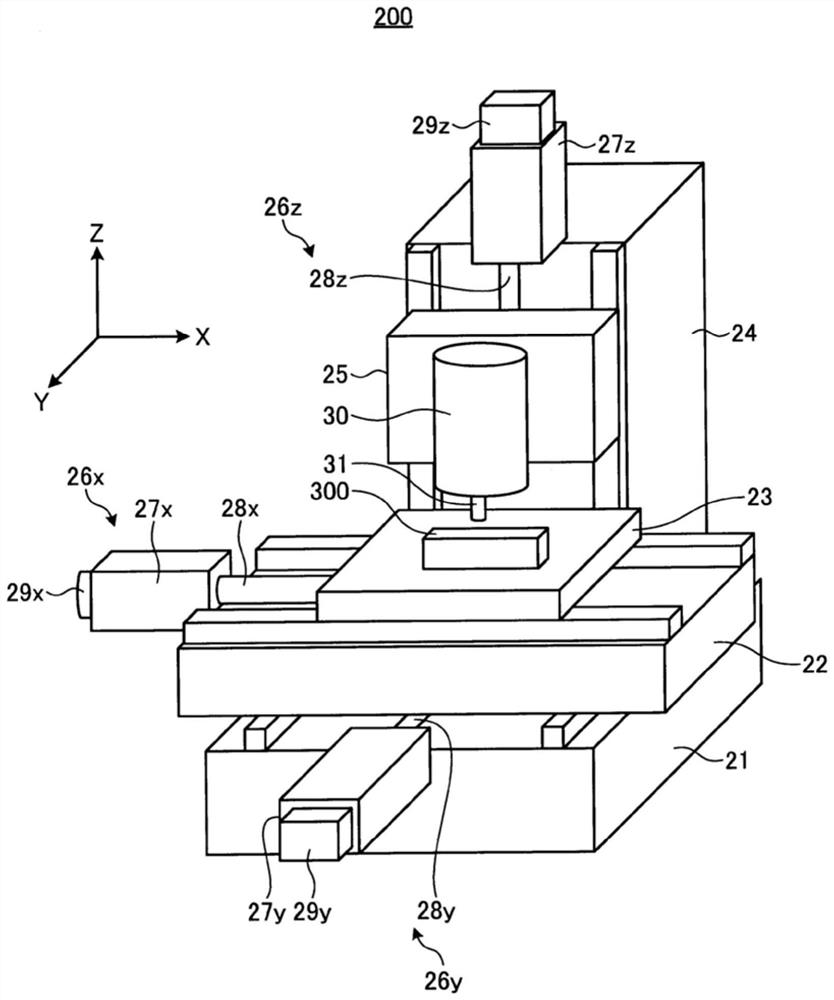

[0023] figure 1 It is a figure which shows the functional structure of the processing simulation display apparatus concerning Embodiment 1 of this invention. figure 2 It is a diagram showing an example of a machine tool and a workpiece to be machined, which are targets of verification work of a machining program. Below, using figure 2 Using figure 1 The function of the processing simulation display device 100 according to Embodiment 1 of the present invention will be described in detail. Hereinafter, the machining simulation display device 100 may be simply referred to as "the machining simulator 100".

[0024] exist figure 2 The appearance of the working machine 200 is shown, and the working machine 200 is an example of a vertical three-axis orthogonal working machine. The working machine 200 has: a stand 21; a saddle 22, which is arranged on the stand 21, and is driven in the y-axis direction; a table 23, which is arranged on the saddle 22; and a column 24, which is ...

Embodiment approach 2

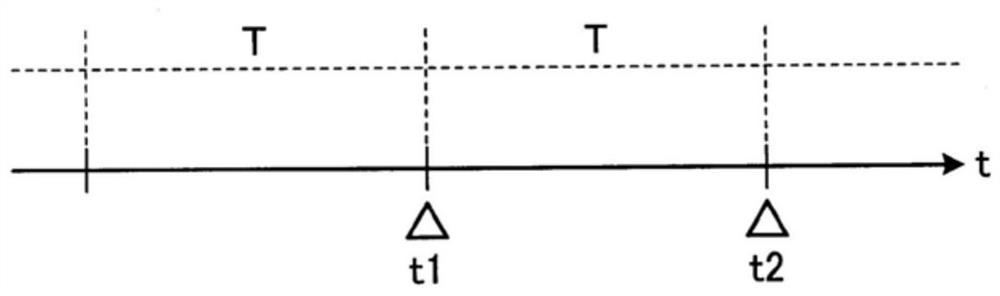

[0054] In Embodiment 1, a configuration example in which the tool display image data 15 generated at the intermediate point is combined with the workpiece display image data 13 generated at the second display update timing t2 was described, but the tool display image generated at the intermediate point The data 15 is combined with the workpiece display image data 13 generated at the first display update timing t1 to obtain the same effect as that of the first embodiment. In Embodiment 2, the structural example which updates the display of the tool display image data 15 based on an intermediate point using the workpiece display image data 13 produced|generated at 1st display update timing t1 is demonstrated. The functional configuration and figure 1 The machining simulators 100 shown are the same, but their operations are different. Use the following Figure 7 , 8 The operation of the machining simulator 100 according to the second embodiment will be described.

[0055] Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com