Anti-corrosion silicon core pipe

A corrosion-resistant, silicon-core tube technology, used in light guides, optics, instruments, etc., can solve problems affecting the protection of internal optical cables, corrosion and damage of the tube body, reduce the growth of microorganisms such as mold, increase the saturated moisture absorption, inhibit the The effect of growth of microorganisms such as mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

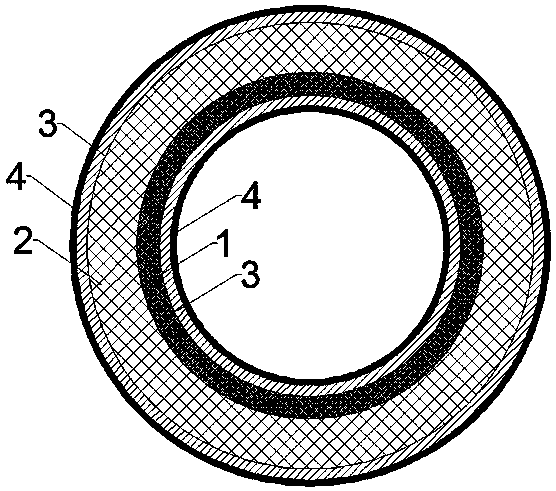

[0021] Such as figure 1 As shown, a corrosion-resistant silicon core tube includes an inner layer 1 and an outer layer 2; the inner layer 1 includes 95wt% of high-density polyethylene, 3wt% of silica gel masterbatch, and 2wt% of color masterbatch. The outer layer 2 includes 91 wt% of high-density polyethylene, 3 wt% of carbon nanofiber, 1 wt% of antioxidant, 1 wt% of heat stabilizer, 2 wt% of dispersant, and 2 wt% of color masterbatch.

[0022] The outer surface of the outer layer 2 and the inner surface of the inner layer 1 are provided with a corrosion-resistant protective layer 3; the corrosion-resistant protective layer 3 includes 80wt% high-density polyethylene, 10wt% activated carbon fiber, 8wt% antibacterial microcapsules, and 2wt% dispersant. Wherein the activated carbon fiber is loaded with magnesium sulfate solution, and the core material of the antibacterial microcapsule is garlic essential oil. The corrosion-resistant protective layer 3 is set by means of synchron...

Embodiment 2

[0025] Such as figure 1 As shown, a corrosion-resistant silicon core tube includes an inner layer 1 and an outer layer 2; the inner layer 1 includes 93 wt% of high-density polyethylene, 4 wt% of silica gel masterbatch, and 3 wt% of color masterbatch. The outer layer 2 includes 89.5 wt% high-density polyethylene, 4 wt% carbon nanofiber, 2.5 wt% antioxidant, 2 wt% heat stabilizer, 0.5 wt% dispersant, and 1.5 wt% color masterbatch.

[0026] The outer surface of the outer layer 2 and the inner surface of the inner layer 1 are provided with a corrosion-resistant protective layer 3; the corrosion-resistant protective layer 3 includes 74.5wt% of high-density polyethylene, 7wt% of activated carbon fiber, 15wt% of antibacterial microcapsules, and 3.5wt% of dispersant . Wherein the activated carbon fiber is loaded with magnesium sulfate solution, and the core material of the antibacterial microcapsule is mustard essential oil. The corrosion-resistant protective layer 3 is set by means...

Embodiment 3

[0029] Such as figure 1 As shown, a corrosion-resistant silicon core tube includes an inner layer 1 and an outer layer 2; the inner layer 1 includes 97wt% of high-density polyethylene, 1wt% of silica gel masterbatch, and 2wt% of color masterbatch. The outer layer 2 includes 92.5 wt% of high-density polyethylene, 2 wt% of carbon nanofiber, 1.5 wt% of antioxidant, 1 wt% of heat stabilizer, 1 wt% of dispersant, and 2 wt% of color masterbatch.

[0030] The outer surface of the outer layer 2 and the inner surface of the inner layer 1 are provided with a corrosion-resistant protective layer 3; the corrosion-resistant protective layer 3 includes 77wt% high-density polyethylene, 15wt% activated carbon fiber, 6wt% antibacterial microcapsules, and 2wt% dispersant. Wherein the activated carbon fiber is loaded with magnesium sulfate solution, and the core material of the antibacterial microcapsule is garlic essential oil. The corrosion-resistant protective layer 3 is set by means of sync...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com