Cable extruded insulation online detection marking system

A technology of extruding insulation and detecting marks, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of low work efficiency, insufficient cable conductor core tension, and complicated operation, and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

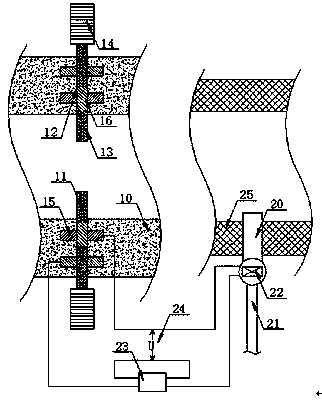

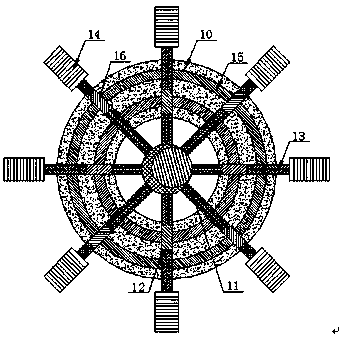

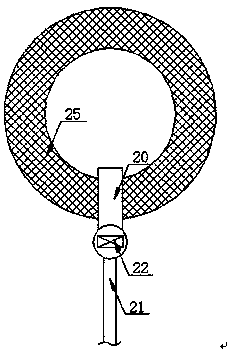

[0018] refer to Figure 1 to Figure 3 , Figure 1 to Figure 3 It is a structural schematic diagram of a specific embodiment of the present invention.

[0019] Such as Figure 1 to Figure 3 As shown, an on-line detection and marking system for cable extrusion insulation includes an insulation detection collar 10 and an abnormal marking ink nozzle 20 arranged sequentially from the upstream to the downstream of the production line. Probes 11, each of the insulation detection probes 11 is arranged along the radial direction of the insulation detection collar 10, and several of the insulation detection probes 11 are equidistant around the axis of the insulation detection collar 10 Distributed arrangement, any two adjacent insulation detection probes 11 are electrically connected to enable the abnormal marking ink spray head 20 to eject ink for marking.

[0020] Specifically, the insulation detection collar 10 is provided with several probe adjustment screw holes 12, each of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com